Exen, Preumatic Blaster

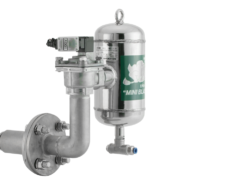

EXEN MMB40 Micro Mini Blaster (MMB)

Products Made In Japan

Manufacturer: EXEN

Model: MMB40

Micro mini blaster for elimination of adhesion, producing an effect with pinpoint accuracy

This product is used for the following applications:

- 01.Prevention of clogging in PVHO piping in the pharmaceutical plant

- 02.Prevention of buildup in grass plant conveyance chute after pruning

- 03.Prevention of adhesion of tonner raw material in piping

-

Features

Mini Mini Blaster is a pneumatic micro mini blaster with a tank capacity of 400mL. This blaster comes with nozzle which provides easy installation, and is suitable for prevention of adhesion of dry powder to the wall surface or for prevention of blockage in a small container.

Suitable for elimination of minor adhesion or blockage

Because of its small body size, Mini Mini Blaster is suitable to be installed to a small tank, hopper, chute section, etc. It is generally suitable for automating the elimination of adhesion and blockage to such an extent that lightly striking the outer surface of container eliminates the problem.。

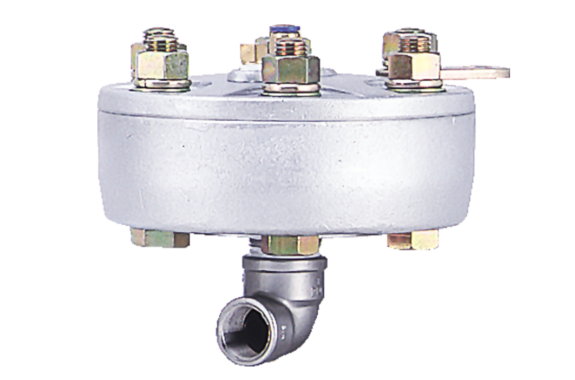

Equipped with two types of nozzles as standard

After drilling a hole in hopper or tank, attach the injection nozzle to the pneumatic Mini Mini Blaster. Nozzles are available in two types: tank welding type and adhesion type if welding is impossible, which is friendly to the site.

Installation without welding

For the welding type of injection nozzle, the reinforced plate and socket are welded to the container and then the nozzle and body are installed form outside of tank. For the no-welding type, the reinforced plate is mounted to the outer surface of tank with adhesive agent and then the socket and body are installed form outside of tank.

1. Check the injection direction with a punch mark.

2. Perform screwing with consideration for co-rotation of nozzle.

3. Screw the nozzle adapter to the edge face of socket.*If the thickness of installation section is less than the standard value, stick the reinforced plate in accordance with the table below.

1. If the injection direction is fixed accurately, perform the spot welding.

2. Check the injection direction with a punch mark.

3. Screw the nozzle adapter until the nozzle insertion portion is pressed.

4. Perform screwing with consideration for co-rotation of nozzle.*If the thickness of installation section is less than the standard value, stick the reinforced plate in accordance with the table below.

Model MMB40 Nozzle plug 5 Nozzle screwing 7 (Imperial System)

Model MMB40 Nozzle plug 5 Nozzle screwing 7 Support for relay piping

Multiple pneumatic Mini Mini Blaster can be operated simultaneously only by installing piping from the subport of tank to the tank in relay. The position where spot injection is required can by operated by one operating valve, which allows reduction in facility cost.

Control by relay knocker control panel

Because the operating principle is the same as pneumatic relay knocker, the operation panel lineup dedicated to pneumatic relay knocker can be used. One control panel can operate multiple knockers, which save the facility cost.

*For the combination of flow aid system, also refer to “Flow aid equipment combination”.Adjustable impact force by the pressure of supply air

In the pneumatic Mini Mini blaster series, just changing the pressure of supply air allows the impact force to be changed by the special mushroom valve (patented). The air pressure is increased if the blockage cannot be eliminated, and is decreased if the impact force is too strong.

* The blue portion in the center is “mushroom valve”

Various types of dedicated controllers for knockers are available

The dedicated control panel is available for operation of Mini Mini blaster series. The control panels include the air operation controller AOC-1B type that can start operation readily without electric power, the timer control panel for solenoid valve control KSE1 type that controls the interval between impacts and the number of impacts, and the control panel HKE series, or the control panel EKE5000 with free input voltage specification from 100 to 240VAC. In addition, the fully air controlled control panel HKA5000A for explosion-proof area is available. (Option)

From left、AOC-1B/KSE1/HKE1100A/HKE5100/EKE5000/HKA5000A Specification

MMB

Model Outlet dia.

Insertion (Screwing)×Nubmer

(mm)Working pressure (MPa)

Injection cycle (Times/min)

Tank capacity

(mL)Air consumption

(L/Time(ANR)Nozzle Assen Weight

(kg)Common models Material MMB40 5.0(5.0)×2 0.3 ~ 0.7 1 ~ 60 400 0.98~2.28 MMB40 Tank portion

(AC7A)4.7 (Imperial System)

Model Outlet dia.

Insertion (Screwing)×Number.

(in)Working pressure (PSI)

Injection cycle (Times/min)

Tank capacity

(Cu.ft)Air Consumption

(cf/time)Nozzle Assen Weight

(lb)Common models Material MMB40 0.2(0.2)×2 43.5 ~ 101.5 1 ~ 60 0.014 0.034-0.080 MMB40 Tank portion

(AC7A)10.4 Two types of discharge port nozzles are included as standard equipment, and two discharge ports are available.

Dimensions, installation, control panel

Product dimensional drawings

Product dimensional table

Model φA B C D E F” G MMB40 175 (149) (103) 76 (18) 3/4 1/4 (Imperial System)

Model φA B C D E F” G MMB40 175 (149) (103) 76 (18) 3/4 1/4 Installation method

MMB40

Model/Number of units selection chart In the case of A: Three units of MMB40 are selected.

In the case of B: Two units of MMB05/12/40 are selected.

Kouei is the Official Distributor/Agent of EXEN.

Other items of Exen

Request the quotation for Exen