Japan, Kanetec, Lifting

Kanetec LEP Electro-Permanent Magnetic Lifma

Products Made in Japan

Manufacturer: Kanetec

Model: LEP

Application

These are electro-permanent magnetic type lifting and transporting magnets that enable the magnetization and demagnetization of the built-in permanent magnet to be controlled electrically. Suitable for steel plates and iron products that have a flat attractive face and can be held on the whole area.

Features

- Using a permanent magnet maintains the holding power during a power failure, enhancing safety.

- Electric controls manage the holding and releasing of these magnets, allowing users to operate them remotely with pushbuttons.

- A system demagnetizes the permanent magnet to release the lifted workpiece. Thus, these magnets don’t attract iron products in other operations, which enhances safety.

- Use the dedicated power source LEPH.

Precautions for use

Rust and scratches on the attractive face adversely affects the holding power.

Inspect/check periodically and make repairs.

Inspect/check periodically and make repairs.

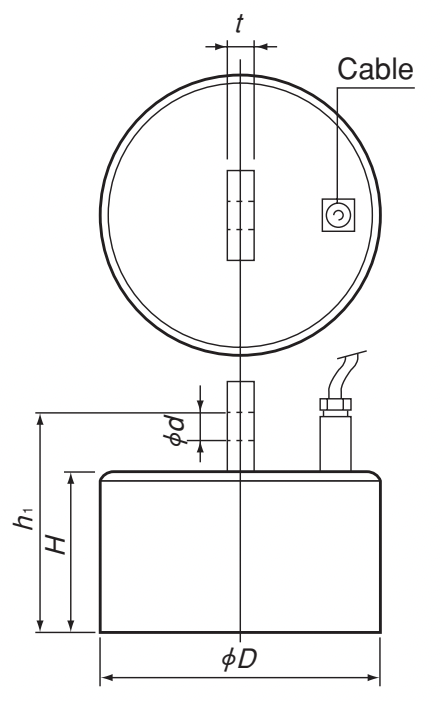

| Model | Lifting Capacity | Dimensions | ||||

| D | H | h | d | L | ||

| LEP-15 | 100kg/ 2201 b | 156(6.14) | 105 (4.13) | 138(5.43) | 16(0.62) | 16(0.62) |

| LEP-20 | 150kg/ 330 lb | 206 (8.10) | 115(4.52) | 154(6.06) | 20(0.78) | 19(0.74) |

| LEP-25 | 350kg/ 771 lb | 246 (9.68) | 125(4.92) | 170(6.69) | 22(0.86) | |

| LEP-30 | 500kg/1102 lb | 296(11.6) | 135(5.31) | 198(7.79) | 25(0.98) | 28(1.10) |

| LEP-35 | 700kg/1543 lb | 354 (13.9) | 150(5.90) | 224 (8.81) | 27(1.06) | 32(1.26) |

| Model | Applicable Shackle |

Rated Voltage | Power Consumption |

Mass | Applicable Control Unit |

| LEP-15 | BC12 (0.47) | 160VDC | 0.38kW | 12kg/ 26.4 lb | LEPH-MW210A |

| LEP-20 | BC14(0.55) | 0.47kW | 22kg/ 48.5 lb | ||

| LEP-25 | BC16(0.62) | 0.45kW | 37kg/ 81.5 lb | ||

| LEP-30 | BB20 (0.78) | 0.57kW | 60kg/132.0 lb | ||

| LEP-35 | BB22 (0.86) | 0.73kW | 85kg/187.4 lb |

- A value indicating a quarter of the max. holding power indicates the lifting capacity.

- Use the Lifma in such a way that workpieces are fully held on the whole attractive face.

- ※Including Cable 3 m.

Kouei is Distributor/Agent of Kanetec.

Other items of Kanetec

Request the quotation for Kanetec