The cell-shaped cross-sectional casing structure of the KITO TD rail helps secure high rigidity, while the lightweight, touch design allows up to a 5-pole conductor to pass through.

Japan, KITO, Lifting

KITO TD Electrical Supply Rail

Product Made in Japan

Manufacturer: KITO

Model: TD Rail

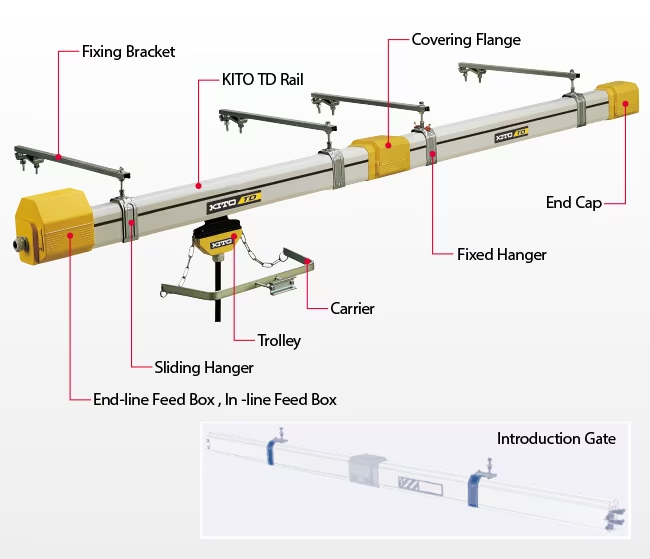

Easily Installable and Removable Electrical Supply Rail

Features

- Lightweight, tough TD rail

- Secure, simple rail joint

- Accessories swiftly fitted and removed.

- Installers: simplicity and flexibility

| Material Used | Self-extinguishing Vinyl Chloride Resin (PVC) |

|---|---|

| Rated Voltage | 750V |

Technical Characteristics

Standard Specification

| Voltage | 750V | Applicable Standards | JIS C8373, EN60439-2, EN60204-32 |

|---|---|---|---|

| Rated Current | 4P/5P-60A, 4P-100A | Ambient Temperature | -20 to 55℃ |

| Protection Grade | IP23 | Ambient Humidity | 90%RH or Less |

Easy-to-USE, Simple KITO TD Rail

Lightweight, Tough TD Rail

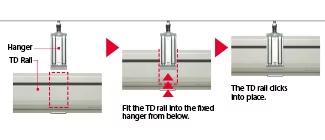

Secure, Simple Rail Joint

Our original special-purpose connection bolt is used on the KITO TD rail joints, allowing easy installation of the rail via firm tightening, even if no torque wrench is used. With a 2-step-structure head, this special-purpose connection bolt separates the 1st-step bolt head when a specified torque is attained, securely connecting the TD rail.

Accessories Swiftly Fitted and Removed

To facilitate fitting and maintenance, the main accessories have been designed for simpler, swifter, tool-free installation. The feeding box and covering flange are clipped on manually, but cannot be removed without the use of a tool, in accordance with regulations.

Innovation is our aesthetic

TD rail offers ergonomics without forgoing aesthetics. Elegant lines, harmonious colors, and coordinated elements result in a dynamic and smart end product, all combining to make this rail an aesthetically successful innovation.

Degree of Protection: High Performance

TD rail simplifies the user choice by offering a complete range of accessories, all ensuring protection of the line against rain (IP23), thanks to an integrated watertight system.

Users: Security and Reliability.

As well as complying with relevant standards and regulations, the TD rail also stands out for its hard-wearing qualities and ease of maintenance, thanks to the use of toll-free fitting of accessories.

Installers: Simplicity and Flexibility.

Thanks to its limited number of parts, the systematic use of easily removed connections, and rapidly fitted accessories (without tools), TD rail offers installers a system which is simple and quick to set up, whatever the location.

Specifications & Dimensions

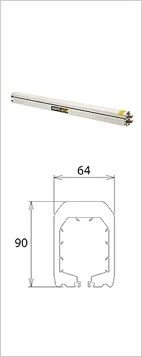

TD Rail

- Self-extinguishing vinyl chloride resin (PVC)

- 4P/5P-60A, 4P-100A

- Rated voltage: 750V

Specifications

※Major capacities example

| Code | Standard Length (m) | Poles-Rating | Mass (kg/m) |

|---|---|---|---|

| ME4604KT | 4 | 4P-60A | 1.8 |

| ME4603KT | 3 | ||

| ME4602KT | 2 | ||

| ME4601KT | 1 |

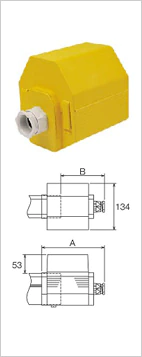

Covering Flange

- Self-extinguishing plastic

- Used to cover the joint of the TD rail.

Specifications

※Major capacities example

| Code | Type | Mass (kg) |

|---|---|---|

| ME1000 | common | 0.2 |

End Cap

- Self-extinguishing plastic

- Mounted to the end of the TD rail.

Specifications

※Major capacities example

| Code | Type | Mass (kg) |

|---|---|---|

| ME1400 | common | 0.3 |

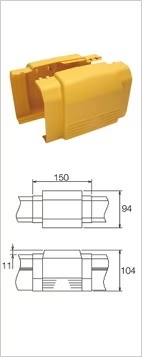

End-line Feed Box

- Self-extinguishing plastic

- Used for supplying the electricity to the TD rail from the end.

Specifications

※Major capacities example

| Code | Cable Connector | Applicable Cable 0.D (mm) |

Mass (kg) | Dimensions (mm) | |

|---|---|---|---|---|---|

| A | B | ||||

| ME1200 | M25 | 13~19 | 0.4 | 181 | 126 |

| ME1230 | M32 | 15~25 | 183 | 128 | |

| ME1250 | M40 | 21~32 | 186 | 132 | |

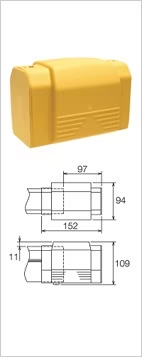

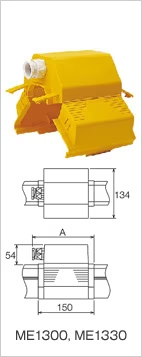

In-line Feed Box

- Self-extinguishing plastic

- Used for supplying the electricity to halfway the TD rail from the line.

Specifications

※Major capacities example

| Code | Cable Connector | Applicable Cable 0.D (mm) |

Poles | Mass (kg) | Dimensions (mm) |

|---|---|---|---|---|---|

| A | |||||

| ME1300 | M25 | 13~19 | – | 0.3 | 169 |

| ME1330 | M32 | 15~25 | 170 | ||

| ME1332 | M40 | 21~32 | 4P | 1.5 | – |

| ME1329 | 5P |

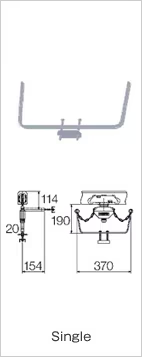

Trolley

- Travels within the TD rail, and provided with a current-collecting brush for receiving the electricity.

- The traveling speed should be 100 m/min. or less.

Specifications

※Major capacities example

| Code | Cable Connector | Type | Poles-Rating | Mass (kg) |

|---|---|---|---|---|

| ME3043KT | M25 | Single | 4P-35A | 0.6 |

| ME4042KT | Double | 4P-35A × 2 | 1.1 | |

| ME5040KT | Triple | 4P-35A × 3 | 1.6 | |

| ME3051KT | Single | 5P-35A | 0.6 | |

| ME4050KT | Double | 5P-35A × 2 | 1.1 | |

| ME5050KT | Triple | 5P-35A × 3 | 1.6 |

Cleaning Trolley

- Used for cleaning the conductor within the TD rail.

Specifications

※Major capacities example

| Code | Poles | Mass (kg) |

|---|---|---|

| ME4514 | 4P | 0.4 |

| ME4525 | 5P |

Sliding Hanger

- Used for fixing the TD rail.

Specifications

※Major capacities example

| Code | Type | Mass (kg) |

|---|---|---|

| ME1510 | common | 0.1 |

Fixed Hanger

- Used for fixing the TD rail.

Specifications

※Major capacities example

| Code | Type | Mass (kg) |

|---|---|---|

| ME1500 | common | 0.1 |

Carrier

- Used for coupling the trolley and a mobile object (crane or/and hoist).

Specifications

※Major capacities example

| Code | Type | Mass (kg) |

|---|---|---|

| ME1600 | Single | 0.6 |

| ME1610 | Double | 1.1 |

| ME1630 | Triple | 2.6 |

Fixing Bracket

- Used for fixing the hanger onto shaped steel, and so on.

Specifications

※Major capacities example

| Code | Length (L) (m) | A × B (mm) | Mass (kg) |

|---|---|---|---|

| ME1700 | 380 | 15 × 20 | 0.5 |

| ME1750 | 500 | 0.6 | |

| ME1760 | 600 | 30 × 30 | 1.0 |

| ME1780 | 850 | 1.2 |

Introduction Gate

- Self-extinguishing vinyl chloride resin (PVC)

- 4P,5-60A, 4P-100A

- Used for mounting/dismounting the trolley halfway the line.

Specifications

※Major capacities example

| Code | Length (m) | Poles-Rating | Mass (kg) |

|---|---|---|---|

| ME4706KT | 2 | 4P-60A | 4.2 |

| ME4756KT | 5P-60A | 4.4 | |

| ME4710KT | 4P-100A | 4.6 |

Options

Current-collecting Brush

- Special-purpose current-collecting brush for the trolley

- The current-collecting brush may be partly worn out.

- Replace the current-collecting brush before it reaches the wear limit.

Cleaning Brush

- Special cleaning brush for the cleaning trolley

- The cleaning brush may be partly deformed or worn out.

- Replace the cleaning brush when it is deformed or worn out.

Connection Bolts

- Special connection bolts used for the TD rail

- When the pre-existing connection bolts are removed while inspecting the TD rail or trolley, ensure they are replaced with new ones.