Bolt & Nut, High Tension Bolt, Kobelco Bolt, Material

KOBELCO BOLT- F8T Hot Dip Galvanized High Strength Hexagon Bolts

Made in Japan

Maker: Kobelco Bolt

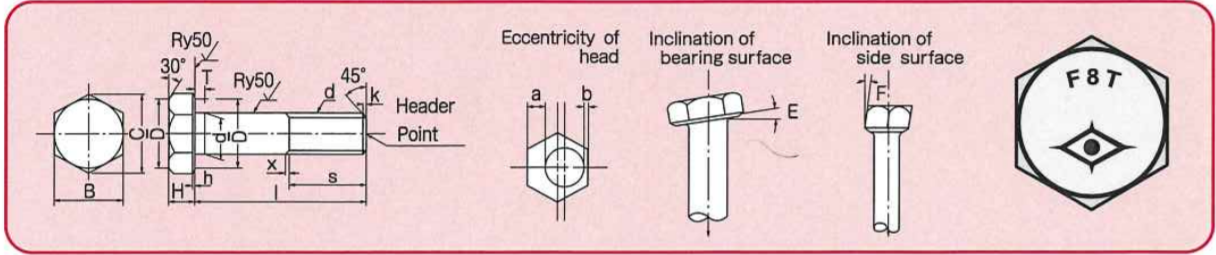

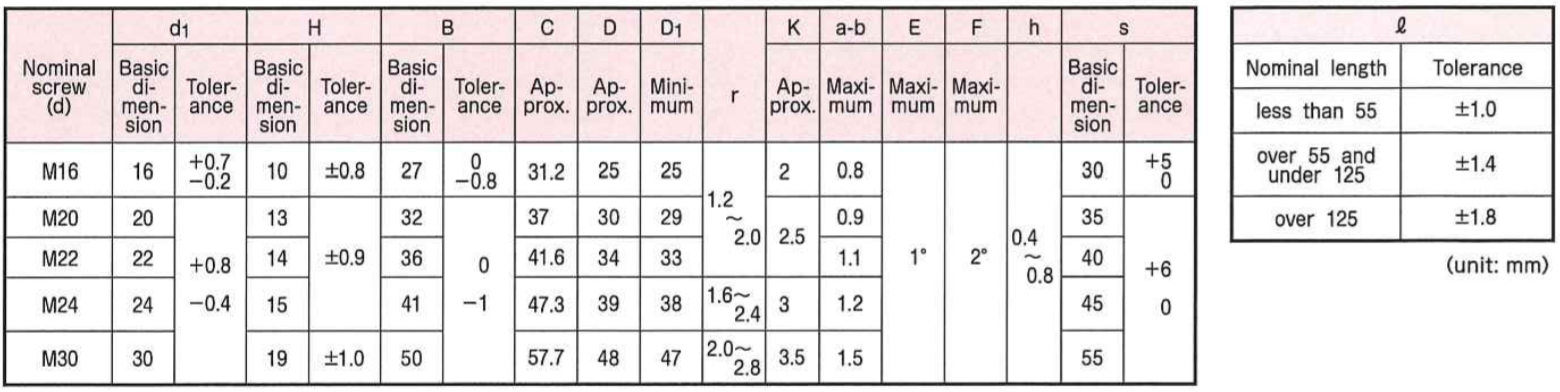

Shape and Dimensions

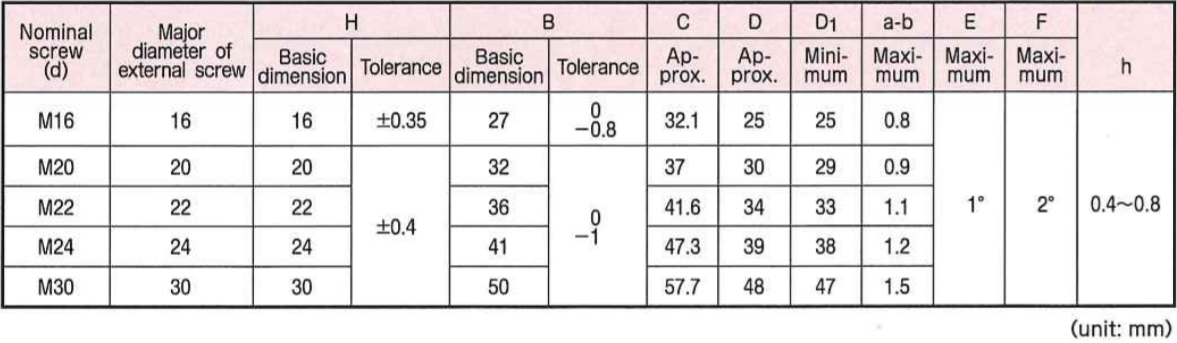

Bolt

Nut

- Over-tap the nuts before galvanizing.

- Overtapping should be less than 0.6mm for M16 and M20 and less than 0.8mm for M22, M24 and M30

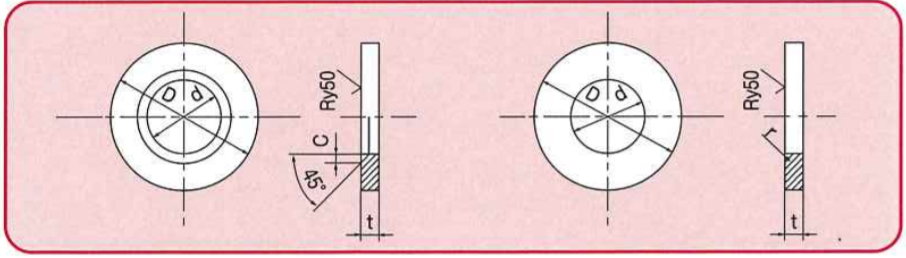

Washer

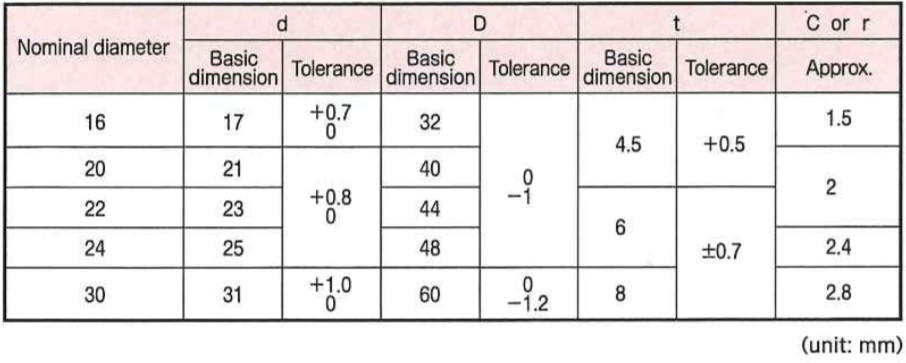

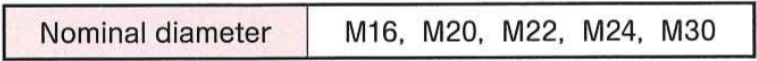

Type and Nominal Diameter

The set observes the Grade 1 (F8T) A standard or JIS B 1186 (sets of high strength hexagon bolt, hexagon nut and plain washer for friction grip joints).

Hot Dip Galvanizing Method

JIS H 8641 Grade 2 HDZ55

Zinc deposit over 550g/m²

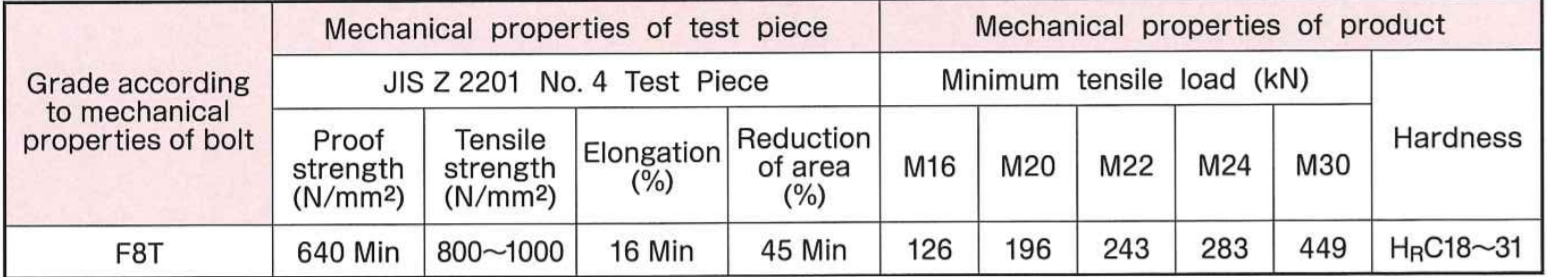

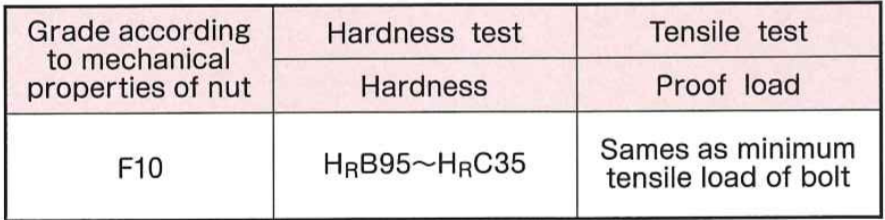

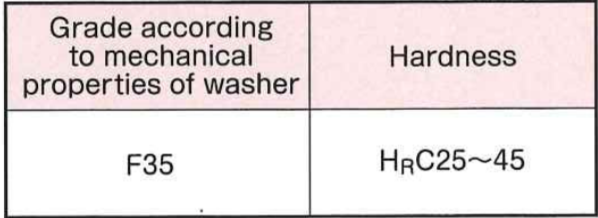

Mechanical Properties

Bolt

Nut

Washer

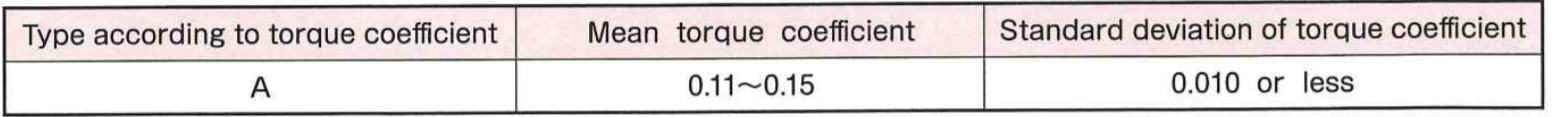

Torque Coefficient of Set

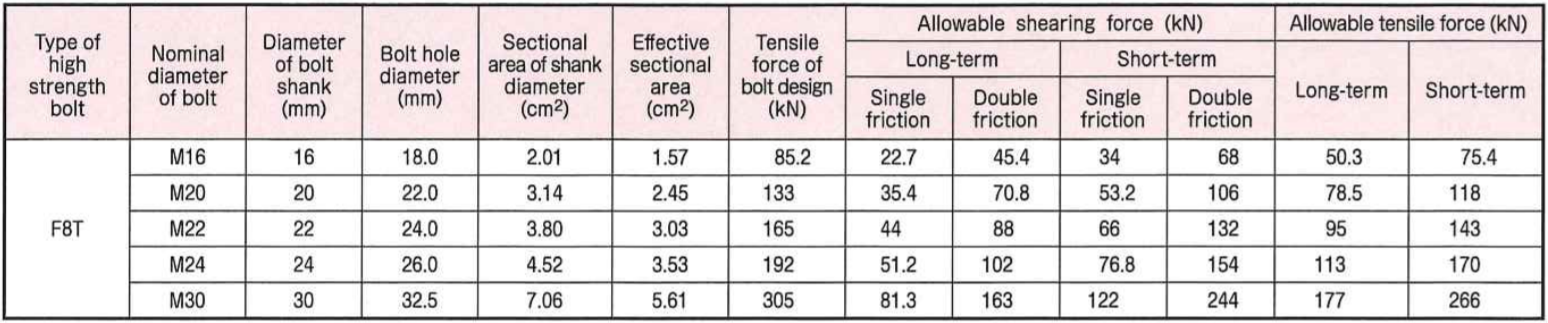

Design (Architecture)

The allowable shearing force of high strength bolts

The allowable shearing force is calculated in accordance with the following equation in which slip factor is regarded as a constant of 0.4, the allowable tensile force observes the “Standard Design of Rigid Structures” indicated by the Japan Architecture Society.

Allowable shearing force = 0.4 x B0 (Tensile force of bolt design)

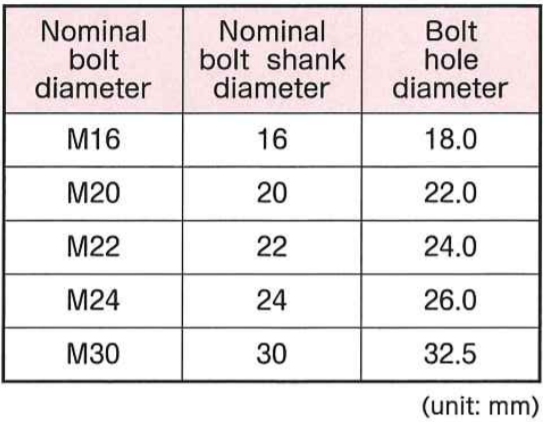

Bolt hole diameter

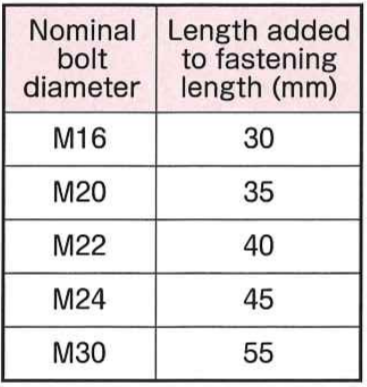

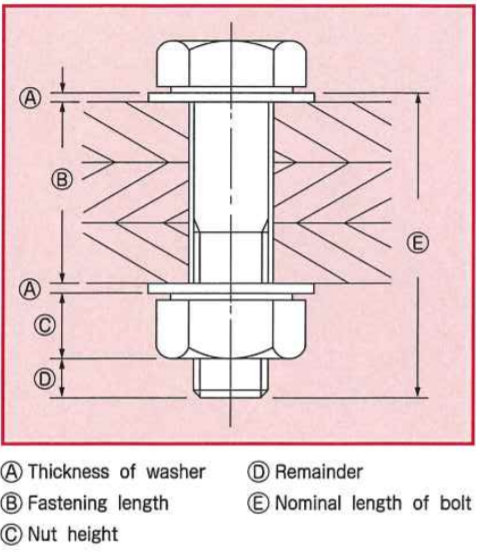

Length of bolt

The nominal length of bolt is determined by adding the value in the table to fastening length

Execution Work

Fastening the high strength bolt

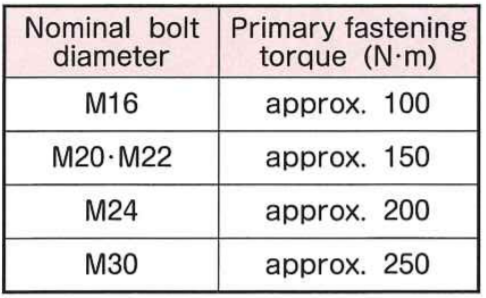

Primary Fastening: Primary fastening includes tightening the temporary fastening bolt, checking the contact with the parts and then turning the nut according to the torque value indicated right, for all bolts.

Marking: Mark the bolt, nut, washer and parts after primary fastening to check the degree of primary fastening, measure the tightness of the nut, check to see all bolts are tightened and to discover any bolts, nut, washer turning together.

Final Fastening: Final fastening is conducted by turning the nut 120°, after primary fastening and marking a group unit. Determine how many times the nut should be turned if the bolt length is over 5 times larger than the nominal diameter of the bolt.

Inspection after fastening: Visually examine the nut to confirm that it is within a -30° ~ +30° range of the specific nut rotation degree.

Characteristics

Over 550g/m² of zinc deposit.

The zinc deposit observes similar thickness as in other materials and boasts of long-term anticorrosive effect since the deposit is thicker than 350g/m² of zinc deposit of the middle strength bolt.

Screw portion of bolts and nuts are threaded before galvanizing

These parts are resistant against electrolytic corrosion since the screw is threaded before galvanizing and then finished with thorough galvanizing to the screw portion of the nuts.

Acid brittleness is eliminated to prevent delayed fracture

There is no danger or delayed fracture since acid brittleness has been eliminated.

Stable Strength

An F8T strength and high toughness is maintained before and after galvanizing. No change in strength is seen as in galvanizing F10T bolt.

Superior Enforcement.

Ideal to enforce nut fastening since the low and stable torque coefficient makes it highly effective in preventing the nut and bolt turning at the same time.

Ideal for Architectural and Civil Engineering Works.

These nuts and bolts have passed the Minister of Construction’s general approval and this can be safely used in buildings. What’s more, hot-dip galvanizing high strength bolt bonding can widely be applied in the accessory facilities of the bridged roads and their accessory facilities such as access corridors, as well as steel radio towers.