Bolt & Nut, Japan, Takenaka Seisakusho

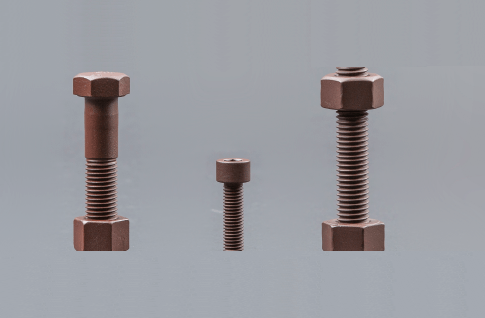

Takenaka Seisakusho TAKECOAT® – CERAMIC1 Coating Bolt

Import from: Japan

Manufacturer: Takenaka Seisakusho

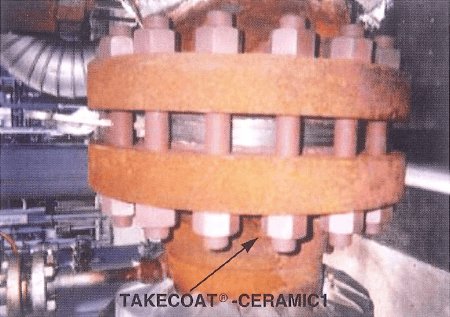

TAKECOAT® – CERAMIC1 Surface Treatment

Realizing prevention of high temperature oxidation at 450°C

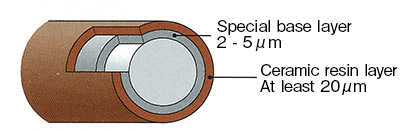

TAKECOAT® -CERAMIC1 is a product featuring heat resistance and long-term durability obtained by the combination of the under-treatment technology and the original ceramic film coating technology. The inorganic heat resistant resin coat film is as thin as 20 to 30.um and is high in lubricity as well. When used in fasteners, its fitting is smooth, the tightening is excellent and the processability is superior. It has been be favorably used in heat-resisting parts demanding prevention of high-temperature oxidation for a long term, such as bolts, nuts, washers and metal members used in heat exchangers and industrial plants.

Features

High heat resistance: No deterioration occurs in long-term continuous use at a maximum temperature of 450’C (in atmosphere) on low alloy steel. The film continues to maintain stability and sound after heating. So, TAKECOAT® -CERAMIC1 protects the seizing of nuts and bolts.

Cold and heat resistance (thermal shock test): Films do not peel off by thermal shock test (100 cycles) of heating to 450’C and cooling in water.

Stable fastening of bolts: In spite of ceramic coating, it is excellent in lubricity, low in torque and uniform making fastening of bolts is easier.

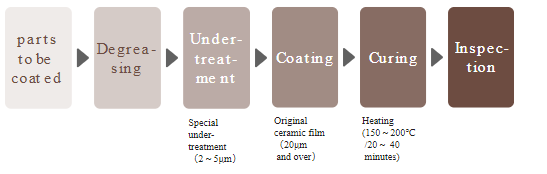

Treating process

By the manufacturing method of Takenaka’s original treatment technology, a thin and uniform film is formed.

There is no danger of hydrogen embrittlement because there is no pickling process.

Related Products

-

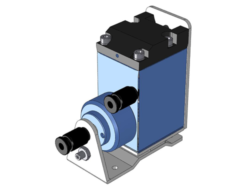

Vessel No.GT-NT05-4 Slide-Off Air Nipper Vertical-type

-

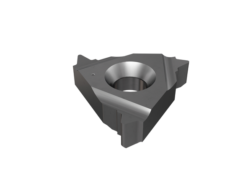

SAKUSAKU 11IR 19BSPT Outer Diameter Threading Insert Tapered Pipe Thread 55°

-

TONE MX200 Mix Socket Wrench Set

-

Line Seiki M16-600 Tally Counters ( Sensor Input Device)

-

BIX BP4/BX4 Long-type/Extension-type Impact Sockets 12.7sq[1/2″]

-

YOSHITAKE TSF-8 Steam Trap/Air Trap