Anchor Bolt, Bolt & Nut, Chuo Tekko

Tie Rod

Product Made in Japan

About Tie Rod

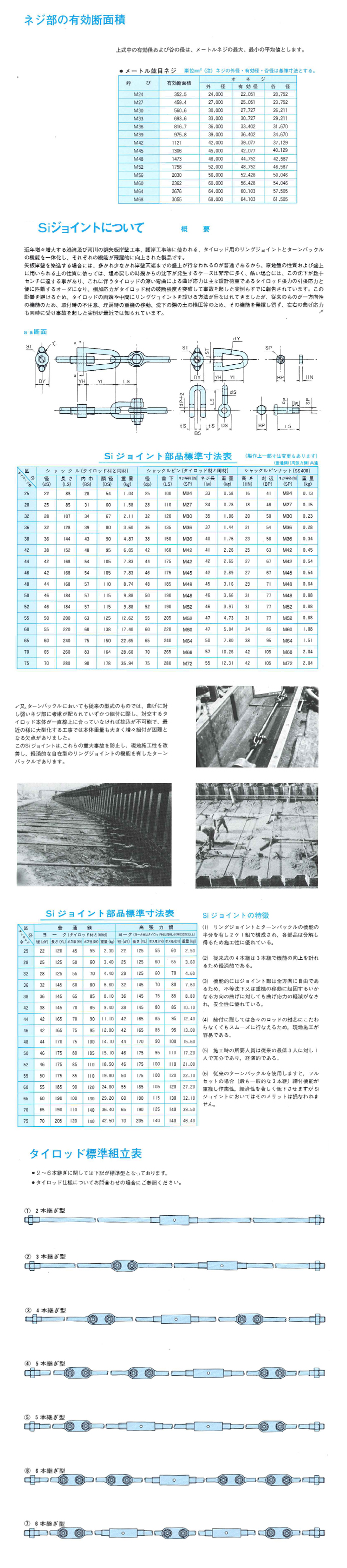

Conventional steel has been used for tie rods used for quays, revetment construction, etc.

In recent years, the size of the construction has been increasing more and more and the size of the tie rod to be used also increases proportionally.

In conventional ordinary steels, problems have arisen in economic efficiency and workability.

As a breakthrough measure, due to recent progress in steelmaking technology, high-tensile steel which is inexpensive and easily available is being used.

Although both companies have merits and demerits, we will list the main features.

Features of ordinary steel (SS material) tie rod

- Results for over forty years

Excellent safety supported by long-term use record

- Excellent ductility and uniform elongation

Even if external stress (bending, etc.) outside the design is added due to excellent rigidity, even when stress concentration occurs, the stress becomes more uniform due to plasticity and it is difficult to break.

- Easy construction management

With the above characteristics, it is well suited for relatively rough use and has high safety, so it is optimal for seawalls of soft ground, erection work, small quay wall and the like.

Characteristics of high tension steel tie rod

- High strength, excellent elongation

It has a high yield point and tensile strength nearly twice that of ordinary steel and has a relatively large elongation rate, so it can be reduced in diameter, and there is no anxiety on handling.

- Ease of handling

Because of its high strength, handling becomes easier as the product weight can be reduced by half compared with ordinary steel.

- High economy

With the above characteristics, if you use high tension steel tie rods, you can save production cost and transportation cost compared to ordinary steel tie rods of the same size. Also, because the tie rods themselves are also lighter in weight, construction is easier, especially at large quay walls, shortening the construction period and reducing construction costs.

With the above characteristics, if you use high tension steel tie rods, you can save production cost and transportation cost compared to ordinary steel tie rods of the same size. Also, because the tie rods themselves are also lighter in weight, construction is easier, especially at large quay walls, shortening the construction period and reducing construction costs.