Japan, Taseto

TASETO COLOR CHECK

Product Made In Japan

Manufacturer: TASETO

Model: Color Check

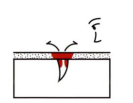

TASETO COLOR CHECK is a Penetrant testing material that is widely used in the inspection of surface discontinuities of Welds, Forgings, Pressure Vessels, Casting, General Metal Work, Power Plant Construction, and Leak Testing.

| Pre-cleaning | Penetrant application | Removal of excess penetrant | Developing | Interpretation |

|  |  |  |  |

| Remove oil, grease and dirt off the test surface with the remover to let flaws open, and then dry the surface well. | Apply the penetrant over the test surface. Dwelling time is in the range of 5 to 60 minutes. | Wipe off excess penetrant with a cloth dampened with the remover. If you use the water washable penetrant, spray shower water. | Apply a thin coat of the well-agitated developer to the test area. Development time is between 10 to 30 minutes. | Find a flaw indication after the developer has dried. |

| Type | Symbols | Properties | Applications | ||

|---|---|---|---|---|---|

| Standard type | Penetrant Remover / Developer | FP-S FR-S FR-Q FD-S | Solvent removable FR-S: Slow drying FR-Q: fast drying | For General Use (-10℃~50℃) | |

| Water washable type | Penetrant | FAW-6 FD-S | Solvent-based penetrant Non-aqueous developer | Water Washable High sensitivity Inspection | |

| PM-6 3W-2 | Water-based penetrant Water-based developer | For Slab Inspection | |||

| Low halogens, low sulfur | Standard type | Penetrant Remover Developer | FP-U FR-U FD-U | Solvent removable type | For nuclear power equipment. Few impurities.S:≦10ppm F:≦30ppm Cl:≦100ppm |

| Water washable type | Penetrant Remover Developer | FPW-U RW-U FD-U | Water washable penetrant Refined Water(aerosol) Non-aqueous developer | ||

| High temp, type | Penetrant Remover Developer | P-HE R-HE D-HE | Testing welds and heat-treated surfaces under high temperatures. (working range 100~200℃) | ||

Standard:

TASETO Color Check standard type meets the requirements of the following standard.

・ MIL-I-25135E/AMS-2644

・ JIS Z2343-2/ISO 3452-2

・ MIL-STD-6866

・ ASTM 1417

・ ASME Boiler & Pressure Vessel Code, Section Ⅴ、Article 6

Coating area:

(Estimates)

| ype | Aerosol (420mL) | Liter Can package |

|---|---|---|

| Penetrant | 5m² | 35 m²/L |

| *Remover | – | – |

| Developer | 4m² | 30m²/L |

The

*The wiping area of the remover differs largely depending on how it is applied.

● Packing units:

420ml Aerosol cans、4-L or 18-L can