| industry | steel, ships |

|---|---|

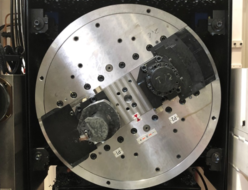

| Work name | Engine (crankshaft) |

| Processing details | Composite machining (oil hole, balance weight mounting surface hole machining) |

| Machine configuration | Single-use machine |

| Transport format | manual |

| specification | φ1250×L13000 Max |

| Made date | 2009.09 |

- Home

- Products

- Yamashina Seiki Horizontal Column Traverse Type Machining Center for Large Crankshaft Processing

Yamashina Seiki

Yamashina Seiki Horizontal Column Traverse Type Machining Center for Large Crankshaft Processing

Product Made In Japan

Manufacture: Yamashina Seiki

This machine is a horizontal column traverse type machining center specially designed to efficiently process the crankshafts of large marine diesel engines. It is possible to continuously machine the inclined oil hole, orthogonal oil hole, balance weight mounting surface, and mounting hole of the crankshaft. The machine includes a column traverse type machining center unit with swivel function, two ejector drill units placed on both the left and right sides of the column, a workpiece mounting bed and six workpiece holders, a positioner and chuck for workpiece indexing. It is made up of more.

Related Products

-

Yamashina Seiki Automatic Fuel Oil Switching Device

-

Yamashina Seiki Deep Hole Drilling Machine For Connecting Rod Lubricating Oil

-

Yamashina Seiki Air Extractor

-

Yamashina Seiki Opposite 500 2-pod Type CNC Facing Machine

-

Yamashina Seiki Column Traverse Method BT50 Spindle Machining Center

-

Yamashina Seiki Conrod/Cap Mating Surface Machining, Horizontal Twin-spindle Machining Center