Kyodo Yushi

Kyodo Yushi GC Grease 350

Product Made in Japan

Manufacturer : Kyodo Yushi

Model: GC Grease 350

High performance grease for couplings which was developed focusing on resistances to wear and leakage especially. Using heat resistance urea thickener, special adhesive, EP agent and solid lubricant, GC Grease 350 excels in resistance to oil separation and adhesion. It offers superior lubrication effect under high surface pressure sliding lubrication conditions.

Characteristics of GC Grease 350

- 1.Extreme pressure property

- In high-load operation, it shows excellent resistance to seizure or wear.

- 2.Flow properties

- Recommended for sliding lubrication under a high surface pressure conditions for its excellent inflow performance onto lubrication surface.

- 3.Leakage resistance

- The separation between the thickener and the base oil is small in amount which prevents leakage from couplings.

- 4.Adhesive properties

- Containing highly adhesive thickener and special adhesive, the grease controls metal contact and spattering caused by centrifugal force.

Main applications and applicable components

- Joints such as gear couplings and spindle shafts of universal joints

Applying a general purpose grease frequently results in softening and leakage due to shearing or centrifugal force caused by rotation, and it could trigger off gear troubles including wear/seizure.

Use of GC Grease 350 reduces the grease amount in use, enabling the life of the machine to extend in addition to preventing environment from pollution caused by grease spattered.

Moreover, it could be applied to lubrication points which require grease to equip inflow performance, adhesion and extreme pressure property.

Typical Property

| Test item | Test method | Test results | |

|---|---|---|---|

| Thickener | – | Urea | |

| Base oil | – | Mineral oil Polymer | |

| Working penetration | ASTM D 217 | 350 | |

| Service temperature range | – | −20°C – 150°C | |

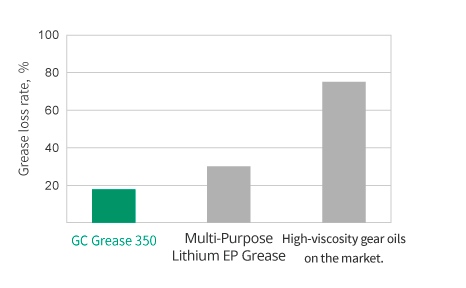

Adhesive properties

- GC Grease 350 boasts the rate of grease loss which is nearly 1/3 of that of high-viscosity gear oils on the market.

ASTM D 2596: Test on grease loss caused by centrifugal force

- Apply 25g of a grease evenly on a 200m diameter steel plate.

- Rotate a plate vertically placed on the test machine at a speed of 500 rpm for 10 min. Then, calculate grease loss rate.

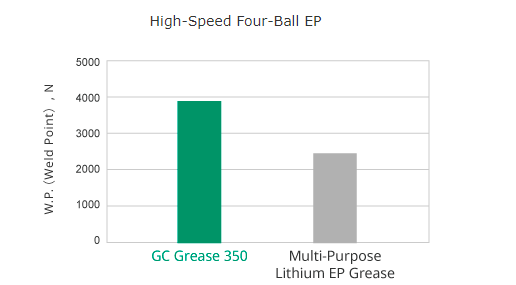

Load carrying capacity

- GC Grease 350 has load carrying capacity higher than those of general purpose EP lithium greases.

High-Speed Four-Ball EP

- The above values are typical properties and we cannot guarantee the applicability of this information in any individual situation. Information regarding the application and service temperature range or typical property values are provided as a guide in selecting the appropriate grease. It is recommended that the user makes its own assessment and determination of the safety and suitability of the product performance/properties for the intended purposes prior to use.

- ※Safety Data Sheet (SDS) of the product should be consulted prior to the use.

- ※The information contained herein is subject to change without notice.

- ※All images used are for illustrative purposes only. (excluding test results).

Related Products

-

Kyodo Yushi Multemp ET-R Rolling Bearing Grease

-

Kyodo Yushi Fluotribo AR-P Special-Purpose Grease

-

Kyodo Yushi Unilite M Water-Resistant Grease

-

Kyodo Yushi Multemp SG Grease For Electromechanical Parts

-

Kyodo Yushi Multemp AC-M Grease For Electromechanical Parts

-

Kyodo Yushi Multemp HL-D Grease For Electromechanical Parts