IHARA SCIENCE CORPORATION

IHARA PSD-B Pre-set Device for Bite Type Fittings

Product Made in Japan

Manufacturer: IHARA SCIENCE CORPORATION

Model: PSD-B

PRE-SETTING DEVICE

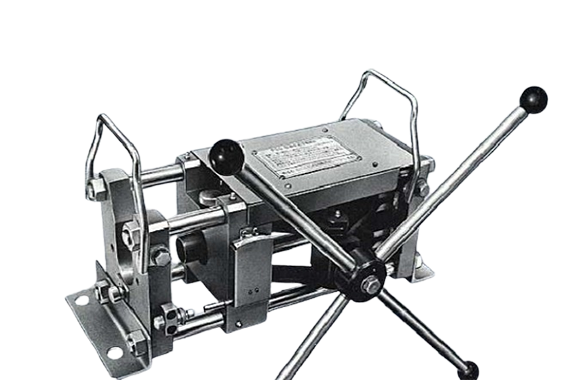

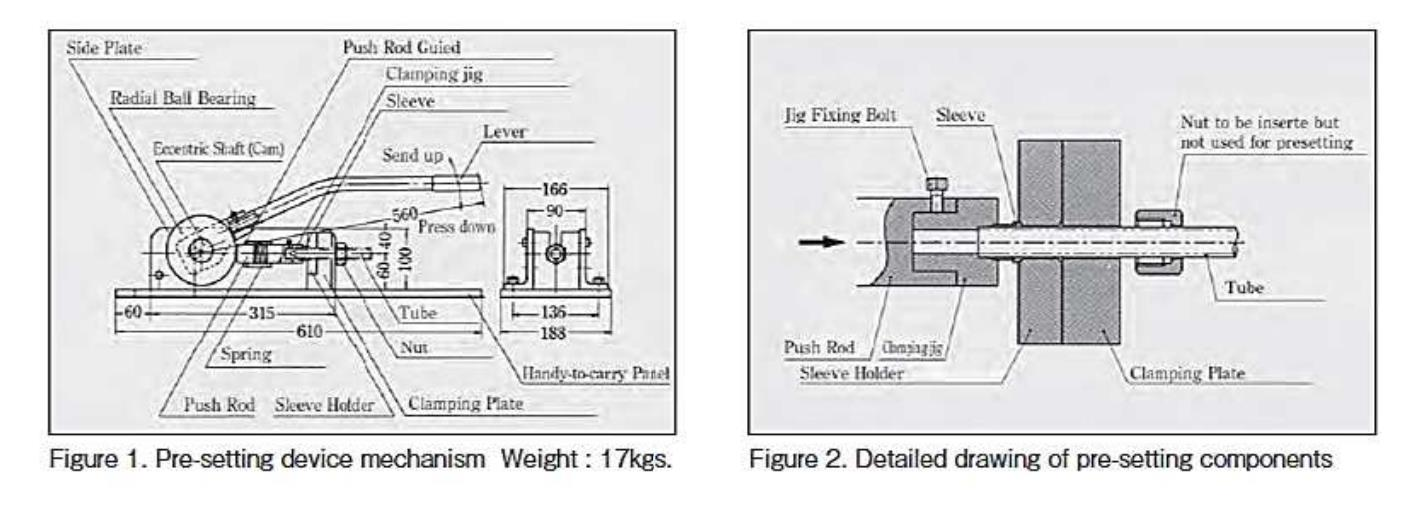

Structure and Function of Pre-Setting Device PSD-B This device performs pre-setting of bite-type fittings within the tube range of 22 to 50mm outside diameter or 1/2B to 1–1/2B by toggle mechanism application as illustrated in the figure below. Upon request, the device for 6mm to 20mm diameter will be available.

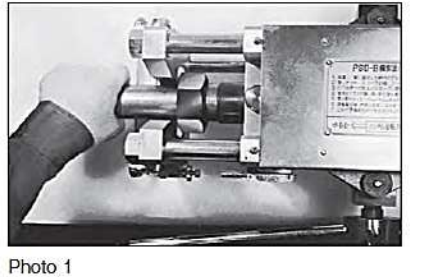

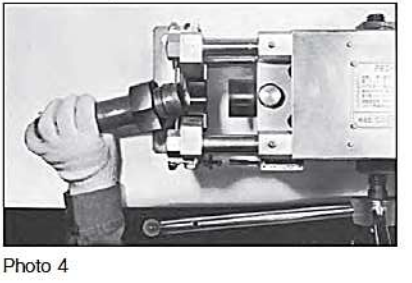

By turning the handle in the right direction, the clamping jig attached to the moving flange slides toward the fixed flange A by the toggle mechanism and forces the sleeve to bite into the tube.

| Outside of Tube | Clamping Jig | Sleeve Helder | Outside of Tube | Clamping Jig | Sleeve Holder |

|---|---|---|---|---|---|

| 22 | PJB22-000E (PSD-BJ-22E) | PJU22—00BE (PSD-BU-22E) | 42 | PJB42-000N (PSD-BJ-42N) | PJU42-00BN (PSD-BU-42) |

| 25 | PJB25-000E (PSD-BJ-25E) | PJU25-00BE (PSD-BU-25E) | 50 | PJB50-000N (PSD-BJ-50N) | Useless |

| 28 | PJB28-000E (PSD-BJ-28E) | PJU28-00BE (PSD-BU-28E) | 1/2B | PJB22—OOOE (PSD-BJ-21N) | PJU22—OOBE (PSD —BU—22) |

| 30 | PJB30—000E (PSD-BJ-30E) | PJU30-00BE (PSD—BU-30E) | 3/4B | PJB27-000N (PSD-BJ-27N) | PJU28—OOBE (PSD —BU—28) |

| 35 | PJB35-000E (PSD-BJ-35E) | PJU35-00BE (PSD—BU-35E) | 1B | PJB34- 000N (PSD-BJ-34N) | PJU35—OOBE (PSD—BU—35) |

| 38 | PJB38-000N (PSD-BJ-38N) | PJU38-00BE (PSD—BU—38) | 11/4B | PJB43-000N (PSD-BJ-43N) | PJU42-00BN (PSD-BU-42) |

| 40 | PJB40—000N (PSD-BJ-40N) | PJU40-00BN (PSD—BU—40) | 11/2 | PJB48-000N (PSD-BJ-48N) | Useless |