- Home

- Products

- Kimoto Acty Dripper (Wastewater Treatment System) Slope and furnace spraying construction materials

Japan, Kimoto Rubber Industry Co.

Kimoto Acty Dripper (Wastewater Treatment System) Slope and furnace spraying construction materials

Product Made in Japan

Manufacturer: Kimoto

Model: Acty Dripper (Wastewater Treatment System)

What are slope and furnace spraying construction materials?

Hoses, nozzles, couplings (fittings), ropes, and safety products used for slope and furnace spraying work. In addition, we handle all hoses and construction materials such as resin hoses, hydraulic and high-pressure hoses.

What is Acty Dripper?

* The main unit has been discontinued. We only sell special “sandbag bags”, “filtration bags” and “neutralizers”.

It is a product that can easily treat cement wastewater on site. The replenishment rate of cement powder is more than 95%. The neutralization process is also easy. Since the neutralized water is discharged into the river, environmental measures are perfect. In addition, cement filtration bags become waste bags, and cleanup after them can be done in a short time.

feature

- ・ Cement wastewater can be easily treated at various sites.

- ・ Pressure drainage can be treated by a spraying machine.

- The capture rate of cement powder is more than 95%, and the neutralization work is easy.

- ・ The cement filtration bag becomes a disposal bag as it is, and it is easy to clean up.

Storage status during transportation

Usage status

Filtration treatment and neutralization methods

Water and cement powder are separated by filtration treatment.

Water and cement powder are separated by filtration treatment.

Fill the neutralization tank with a neutralizer. After stirring and checking the pH value, discharge.

Fill the neutralization tank with a neutralizer. After stirring and checking the pH value, discharge.

filtered cement powder. Dispose of it as it is.

filtered cement powder. Dispose of it as it is.

specification

| size | 1,000 mm × 1,300 mm× H 2,310 mm (H 1,560 mm at the time of delivery) |

|---|---|

| Shipping weight | 260㎏ |

| Tank capacity | Top: 665 liters Bottom: 840 liters |

| Wastewater Treatment Capacity | 7~20 l/min *Varies depending on material concentration |

| Cement powder recovery capacity | Maximum volume: 70 liters / 1 time (4 bags × 17.5 liters) |

| Dimensions (inner diameter× total length) | φ200×750mm (20 sheets as standard) |

|---|---|

| material | polyester |

| ingredient | Citric acid (main component) |

|---|---|

| Neutralization Capacity | 1 piece/5 liters of treated water pH 12~13 |

| Quantity | 10g/piece (375 pieces as standard) |

| Filtration Bag | 20 sheets/case or 100 sheets/case |

|---|---|

| Acty sandbags | 100 sheets/case *No neutralizer |

| Neutralizers | 375 pcs/case (with pH measuring paper) |

| other | Neutralization tank, greywater pump, agitator |

* For sandbags, only part of the cement and sand is removed by filtration. Please note that it does not filter completely.

Usage

- Attach sandbags to the activi ripper.

- Drain the gun wash water.

- Filter some of the cement and sand with sandbags.

- Wastewater accumulates in the circulation tank.

- The circulating water is used again for cleaning, etc. (Not available for kneading water)

- Finally, a filtration bag is installed to capture the cement content of the wastewater.

- Carry out neutralizer work and drain.

Related Products

-

Saitama Seiki U-TOOL U-810-8 Low-speed Screwdriver

-

SANKO TITAN PACN-10A-SI Pangaea Canyon Stylish LightWeight

-

SAKUSAKU 16ER 11W Outer Thread Cutting Insert Whitworth 55°

-

Organo D-7 DS-10C Filters

-

Watanabe AP-101 Digital panel meter for DC voltage/current – DC Meter

-

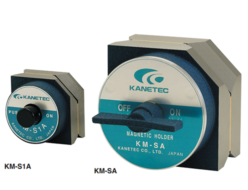

Kanetec KM-SA HEXAGONAL MAGNETIC HOLDER