Japan, Kimoto Rubber Industry Co.

Kimoto Test Facilities Factory Equipment

Product Made in Japan

Manufacturer: Kimoto

Model: Test Facilities

Features

Rubber vulcanization tester

We measure the storage stability of compound rubber and look at the guidelines for processability when molding. Perform a physical property test (K6300-1) of unvulcanized rubber. For use in quality control and formulation research, it measures the initial viscosity, minimum viscosity, scorch time, and vulcanization rate of compound rubber.

We measure the storage stability of compound rubber and look at the guidelines for processability when molding. Perform a physical property test (K6300-1) of unvulcanized rubber. For use in quality control and formulation research, it measures the initial viscosity, minimum viscosity, scorch time, and vulcanization rate of compound rubber.

Automatic Mooney Viscometer

Perform a physical property test (K6300-1) of unvulcanized rubber. We look at the stability of the kneading condition and use it as a guide for the moldability in the mold. It is mainly used for quality control to measure the viscosity, minimum viscosity, scorch time, and vulcanization rate of compound rubber under specified conditions.

Perform a physical property test (K6300-1) of unvulcanized rubber. We look at the stability of the kneading condition and use it as a guide for the moldability in the mold. It is mainly used for quality control to measure the viscosity, minimum viscosity, scorch time, and vulcanization rate of compound rubber under specified conditions.

Universal testing machine

Vulcanized rubber is stretched to measure strength and elongation, or compressed to determine the stress that changes over time. Tensile test (K6251), tear test (K6252), stress and strain test at low deformation (K6254), adhesion test (K6256), stress warming test (K6263), and heat aging specimens in gear ovens can be performed for tensile testing.

Vulcanized rubber is stretched to measure strength and elongation, or compressed to determine the stress that changes over time. Tensile test (K6251), tear test (K6252), stress and strain test at low deformation (K6254), adhesion test (K6256), stress warming test (K6263), and heat aging specimens in gear ovens can be performed for tensile testing.

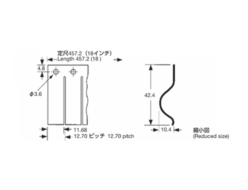

Nominal capacity: Maximum load 1000kgf Tensile

speed: 0.5mm~500mm/min, 13 levels of speed change possible

Gear oven with air change meter

Tensile test specimens, test pieces for compression set, immersion test to determine the oil resistance of vulcanized rubber (K6258), contamination test to check the degree of discoloration due to contact with rubber and different materials (K6267) It is used for heat aging treatment and heating acceleration to speed up the effect. In addition, the air change meter can be used to change the air replacement rate (times/hour) in the chamber to add warmth to the aging process in addition to temperature and time.

Tensile test specimens, test pieces for compression set, immersion test to determine the oil resistance of vulcanized rubber (K6258), contamination test to check the degree of discoloration due to contact with rubber and different materials (K6267) It is used for heat aging treatment and heating acceleration to speed up the effect. In addition, the air change meter can be used to change the air replacement rate (times/hour) in the chamber to add warmth to the aging process in addition to temperature and time.

Test Presses

It is used to produce test pieces, compression set, and test specimens for adhesion tests with the optimum vulcanization time obtained from the vulcanization behavior of the compound rubber.

It is used to produce test pieces, compression set, and test specimens for adhesion tests with the optimum vulcanization time obtained from the vulcanization behavior of the compound rubber.

Digital hardness tester

There are various types of vulcanized rubber, from soft to hard, but this is objectively displayed in numbers. A durometer hardness test (K6253) is performed to measure the hardness of vulcanized rubber. The photo shows what is called a Type A durometer.

There are various types of vulcanized rubber, from soft to hard, but this is objectively displayed in numbers. A durometer hardness test (K6253) is performed to measure the hardness of vulcanized rubber. The photo shows what is called a Type A durometer.

Electronic hydrometer

It is used to measure the specific gravity of vulcanized rubber and check whether it is providing a stable material supply. Specific gravity is an important value that is also used to calculate the weight of materials in making products.

It is used to measure the specific gravity of vulcanized rubber and check whether it is providing a stable material supply. Specific gravity is an important value that is also used to calculate the weight of materials in making products.