Daiichi Keiki, Japan

Daiichi Keiki DDIT/DDIP Diaphragm Digital Pressure Gauge

Manufacturer: Daiichi Keiki

Model: DDIT/DDIP

Features

The diaphragm digital pressure gauge, particularly the DI series, is equipped with a diaphragm device, enabling it to measure pressures of corrosive fluids and gases, which was previously challenging. These gauges excel in applications such as etching processes, developing devices, and stripping equipment in LCD and PDP manufacturing plants. By integrating a diaphragm device with a digital pressure gauge, it becomes possible to handle measurements in environments where corrosive fluids and gases are present.

Structure

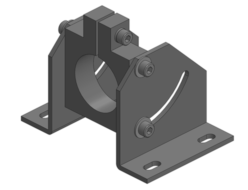

The display section is isolated from direct contact with the measurement fluid by a diaphragm, and a suitable liquid is enclosed to smoothly transmit the pressure applied to the diaphragm to the display section. The diaphragm has a simple plate-like shape, allowing for the selection of various materials that match the measurement fluid.

Application

This device is commonly used as a pressure gauge for highly corrosive fluids, and due to its structural ability to increase the pressure transmission area and the diameter of the connection part, it is also widely used for measuring the pressure of high viscosity substances. It is suitable for industries such as petroleum, paper manufacturing, and chemical production.

Features of the Diaphragm Digital Pressure Gauge:

The flange part of the diaphragm digital pressure gauge integrates a diaphragm device directly connected to the pressure-receiving part, with liquid sealed inside under vacuum.

A wide range of lower flange materials is available, including PVC, HT-PVC, PP, and Teflon.

| ||||||||||||||||||||||||||||||||||

| Digital pressure gauge display | |||||

| Connection | Flange material | Diagram material | Lower flange material | Tightening bolt material | Filled liquid |

| R3: R3/8 G3: G3/8B R4: R1/2 G4: G1/2B F10: 10k-10A F15: 10k-15A F20: 10k-20A F25: 10k-25A F40: 10k-40A F50: 10k-50A | 1:PVC2: SUS304 3: S25C | 1: Teflon2: Tantalum 3: SUS316L + Teflon 4: SUS316L + rubber lining 5: EPDM rubber | 1:PVC2: HT-PVC (heat-resistant vinyl) 3: PP4: Teflon | 1:PVC2: SUS304 | 1: Ultra pure water2: Propylene glycol 3: Glycerin4: Silicon 5: Daifroil |

*Please refer to the diaphragm pressure gauge catalog for details.

Specification

| Display specifications | |||||

| DDIT | DDIP | ||||

| Display | 1999 31/2 digit red LED (character height 14.2mm) | 4-digit red LED (character height 14.2mm) | |||

| Sampling rate | – | 1 to 500 times/sec changeable | |||

| Display conversion speed | Approximately 2.5 times/second | 1 to 25 times/second, changeable | |||

| Comparison setting output | Number of output points | – | 2 points (setting values can be set arbitrarily) | ||

| Comparison conditions | – | Hi setting: Measured value ≧ Set value = Output ON Lo setting: Measured value ≦ Set value = Output ON (Hi or Lo can be set arbitrarily for each of the two points) | |||

| Comparison setting range | – | -5000~5000 | |||

| Hysteresis setting range | – | 0-999 | |||

| Contact rating | – | Photomos relay output AC/DC combined load voltage 240V, load current 120mA or less | |||

| Operating temperature and humidity range | 0~50℃, 35~85%RH (no freezing or condensation) | ||||

| Sensor type specifications | ||||

| Model | L:General low pressure | T:General medium pressure | Q:General-purpose medium pressure | |

| Pressure span | 50・100・200 ・500kPa 50・100・200 ・500kPa abs | 1MPa | 1MPa | |

| Nonlinearity | ±0.2%RC | ±0.3%RC | ±0.8%RC | |

| Hysteresis | ±0.1%RC | ±0.3%RC | ±0.8%RC | |

| Allowable overload | 300%RC | 150%RC | 150%RC | |

| Limit overload | 400%RC | 200%RC | 200%RC | |

| Temperature effect at zero point | ±0.02%RC/℃ | ±0.02%RC/℃ | ±0.02%RC/℃ | |

| Temperature effect on output | ±0.02%RC/℃ | ±0.02%RC/℃ | ±0.1%RC/℃ | |

※R.C. (Rated Capacity) refers to the pressure range.