IHARA SCIENCE CORPORATION

IHARA DVKA Series Diaphragm Valve For High Pressure Service

Product Made In Japan

Manufacturer: IHARA SCIENCE CORPORATION

Model: DVKA Series

DVKA Metal Diaphragm Seal Valve(21MPa

Features

DVKA Series Diaphragm Valves are designed compact to be applied for UHP high-pressure services.

Diaphragm made of Co-Ni alloy is mounted to realize highly airtight and high durability.

Oil or Grease-free treatment through precise cleaning on the internal media contact surface.

Assembly and Packaging in the clean room.

An indicator to find Open/Close easily is installed on the handle of the manual valve.

Please let us know when you need High-pressure gas products.

| Nominal Size | Size | 1/4″ |

|---|---|---|

| Work Pressure | Pressure | Vac. ~ 21MPa |

| Work Temperature | Temperature | -10°C ~ +80°C (Manual), -10°C ~ +40°C (Pneumatic) |

| Cv Value | Value | 0.1 |

(※1) In the case of PCTFE sheet

(※2) In the casef VTF Male connection.

| Detected Leak Inner | Leak Rate | ≤ 3 x 10^-10 Pa m³/sec |

|---|---|---|

| Detected Leak Outer | Leak Rate | ≤ 1 x 10^-10 Pa m³/sec |

| Weight | Weight | 270g (Manual), 350g (Automatic) |

| Internal Volume | Volume | 1.0cc |

| Work Durability | Durability | Over 50,000 (Manual), Over 400,000 (Automatic) |

(※3) In the case of VTF Male connection under valve Open.

(※4) In-house Test:21MPa N2 gas sealed

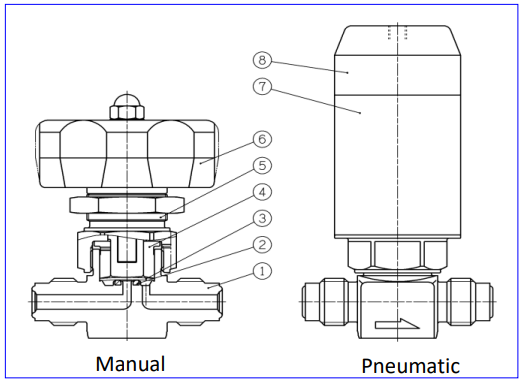

Materials of Main Parts

| Parts Name | Material | |

| 1 | Body | 316L SS |

| 2 | Seat | pctfe’*1’ |

| 3 | Diaphragm | Co-Ni Alloy |

| 4 | Diaphragm Retainer | 630 SS |

| 5 | Bonnet | 304 SS |

| 6 | Handle’*2’ | Aluminum Alloy |

| 7 | Cylinder | |

| 8 | Cylinder Cover |

(※1)PI, PEEK, PFA, etc. are available on option.

(※2)Contact us for Lock Out Tag Out (LOTO) options.

Nomenclature of Part Number

DVKA – ① ② – ③ – ④

Ex) DVKA – 4VM – NC – EP [1/4″VTF Male connectin, Automatic, Normal Close, Electrolytic polishing]

1. Size

| Mark | Size |

|---|---|

| 4 | 1/4″ |

2. Connection

| Mark | Connection |

|---|---|

| VM | VTF (Male) |

| VF | VTF (Female) |

| D | BI-Lok |

3. Operation

| Mark | Operation |

|---|---|

| Manual | |

| NC | Normal Close |

| NO | Normal Open |

4. Internal Finishing

| Mark | Internal Finishing |

|---|---|

| EP | Electro-Polish (≤ Ra 5 µ inch) |

| BA | Machining (≤ Ra 10 µ inch) |

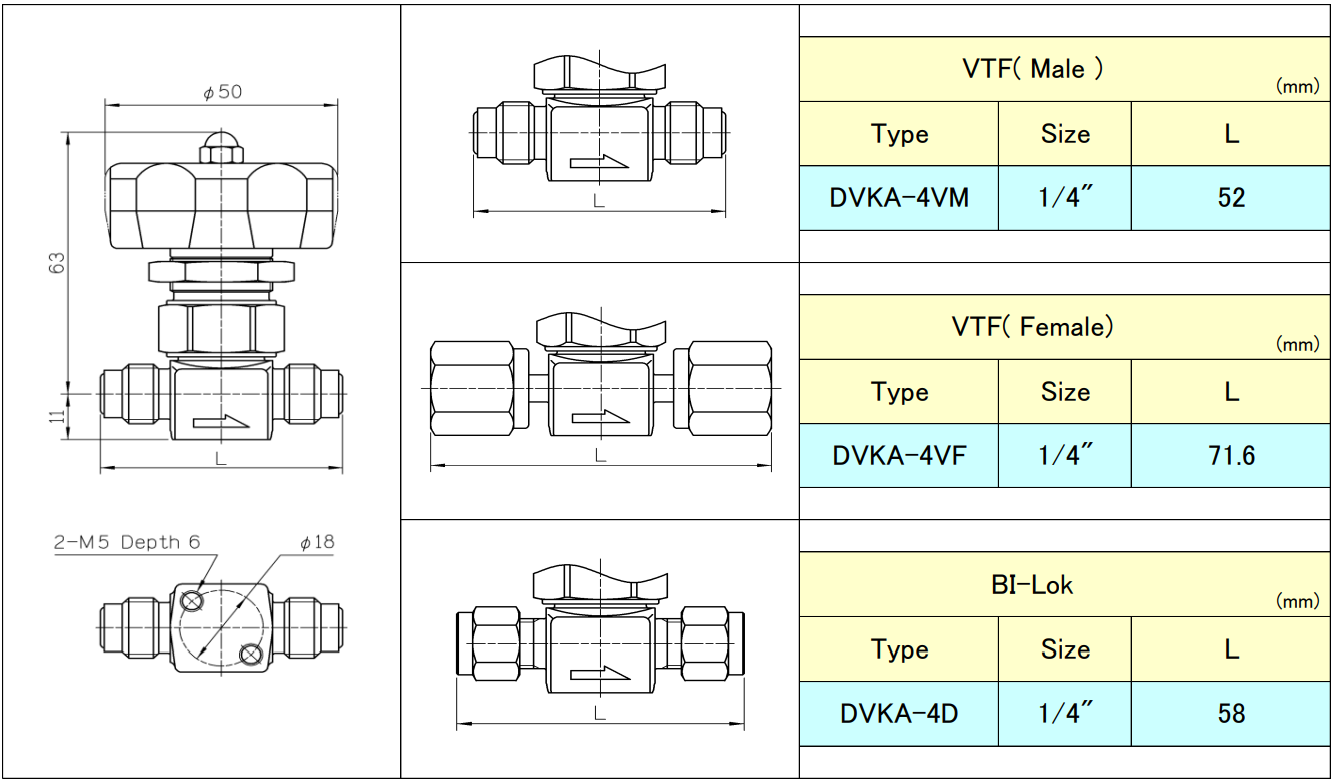

Dimensions (Manual)

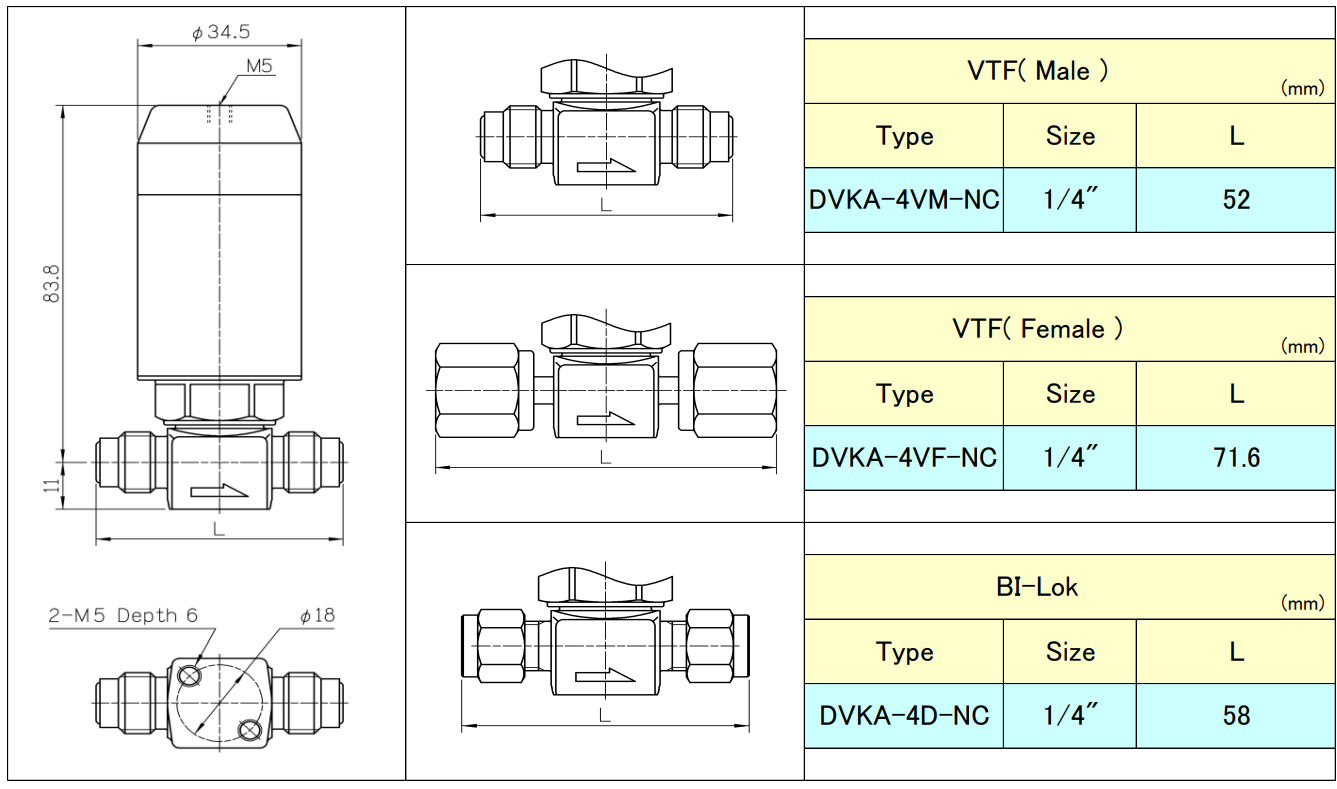

Dimensions ( Pneumatic )

Related Products

-

IHARA WEARLESS SINGLE ACTION PISTON VALVE ADAPTED FOR HEMING SEALER

-

IHARA VNN Series Needle Stop Valves

-

IHARA VH series Union Bonnet Needle Stop Valves for High Temperature Service

-

IHARA DVF Series Lightweight and Compact Metal Diaphragm Valve

-

IHARA PSD-H Series Hydraulic Pre-Setting Device for Steel Tube Bite Type Fitting

-

IHARA I-Fit Single Ferrule Fitting For Stainless Tubing