Japan, Showa Measuring Instruments

Showa Measuring Instruments Strain Gages

Made in Japan

Manufacturer: SHOWA MEASURING INSTRUMENTS Co., Ltd.

Features

In our modern society, machines and structures are essential for safe, smooth living, requiring confirmed functionality and safety. Strain gages are key sensors that detect and measure strain and stress, ensuring these facilities remain safe.Strain gages, fundamental sensors for detecting and measuring strain and stress, play a key role in ensuring the safety of these facilities.

The history of strain gages dates back to 1938 when Simmons & Ruge first designed bonded type strain gages in America. In 1962, SHOWA Company began manufacturing foil grid type strain gages in Japan, marking the first of its kind. These devices are essential for assessing the strength and properties of materials like metals, rubber, plastics, and ceramics used daily.

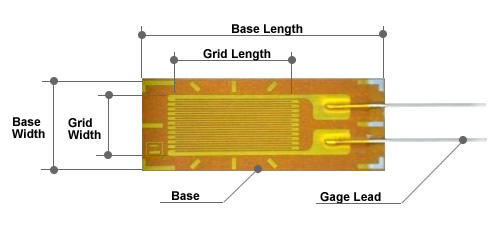

Basic Structure

Strain gages are made of a metallic foil film, a few microns thick, attached to an insulated sheet like polyimide or polyester. Manufacturers use photo-etching to cut the foil into strain gage shapes based on patterned negative film masks. They then trim these patterns to achieve a standard resistance value that meets strain gage requirements. For general applications, manufacturers also categorize the thermal resistance factors of the foil films into three groups. These correspond to the thermal elongation factors of three popular materials: mild steel at 11ppm, stainless steel at 16ppm, and aluminum alloy at 23ppm, allowing the strain gages to self-compensate for temperature effects when specified in orders.

Standard Specifications

The table categorizes strain gage bases by material: polyester (FA series) and polyimide (MA series). The FA series, with its diverse types and specifications, is perfect for general strain measurements over a wide range. Conversely, the MA series excels in medium and high-temperature measurements and fits well in industrial or scientific sensors. It lists model names, ratings, dimensions, frequency responses, and masses (in mm).

| Specification | FA series | MA series | Unit and Note |

|---|---|---|---|

| Gage Length | 0.3mm to 60mm | 0.3mm to 60mm | standard |

| Gage Resistance | Within ±0.3% of the nominal resistance | Within ±0.3% of the nominal resistance | 120Ω to 1000Ω |

| Foil Material | A : Cu-Ni Alloy | A : Cu-Ni Alloy | |

| Base Material | Polyester | Polyimide | |

| Gage Factor | 2.00 (Nominal) | 2.00 (Nominal) | 1.90 to 2.10 |

| Measurable Strain | 2 to 4% maximum | 2 to 4% maximum | Up to 10% with yielding strain |

| Temperature Range | -30℃ to +80℃ | -30 to +180℃ | |

| Thermal Output | ±2μst/℃(RT to +80℃) | ±2μst/℃(RT to +160℃) ±5μst/℃(+160℃ to higher) | Compensated temperature range |

| Gage Factor Change with Temperature | ±0.015%/℃ | ±0.015%/℃ | Refer to “Tech Information” |

| Fatigue Life | More than 1×105 reversals | More than 1×105 reversals | at ±1000×106 strain |

| Applicable Linear Expansion Coefficient | Common steel Stainless steel Aluminum alloy | Common steel Stainless steel Aluminum alloy | 10.8ppm/℃ 16.2ppm/℃ 23.4ppm/℃ |

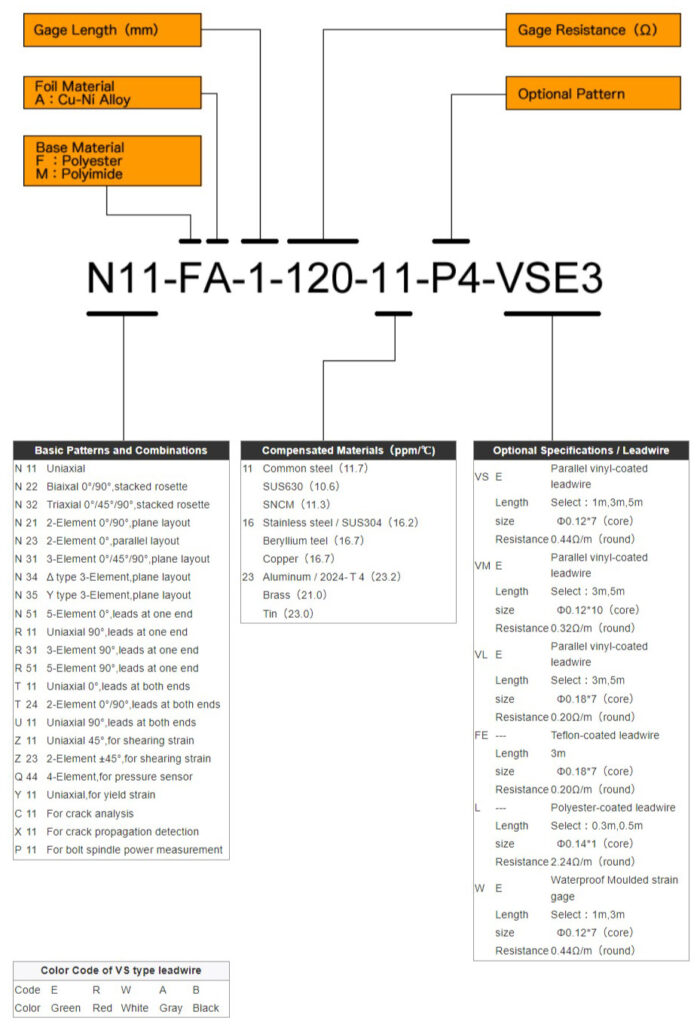

Configurations

Showa Measuring Instruments Co., Ltd. designates its strain gages based on basic grid patterns and additional signs that indicate the material of the grid holder, the foil material, the grid length, and other characteristics

The vinyl color of parallel leadwires of uniaxis strain gages is green (standard) and its symbol is “E”. Vinyl color can sometimes be changed if required.

The vinyl colors of parallel leadwires of biaxes strain gages are green (Symbol: “E”) and red (Symbol: “R”).

Triaxial strain gages have parallel leadwires in green (“E”), red (“R”), and white (“W”).

However, their designations, like VS1 or VS3, do not include these color symbols.