IHARA SCIENCE CORPORATION

IHARA MHM-MMF-MCF-MHF Metal Flexible Hose

Product Made In Japan

Manufacturer: IHARA SCIENCE CORPORATION

Model: MHM-MMF-MCF-MHF Series

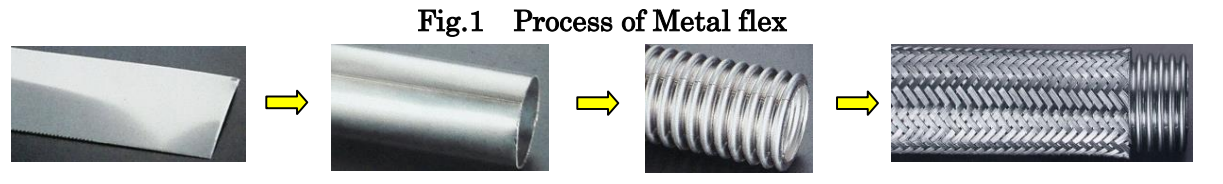

Metal Flexible Hose (abbreviated Metal flex)

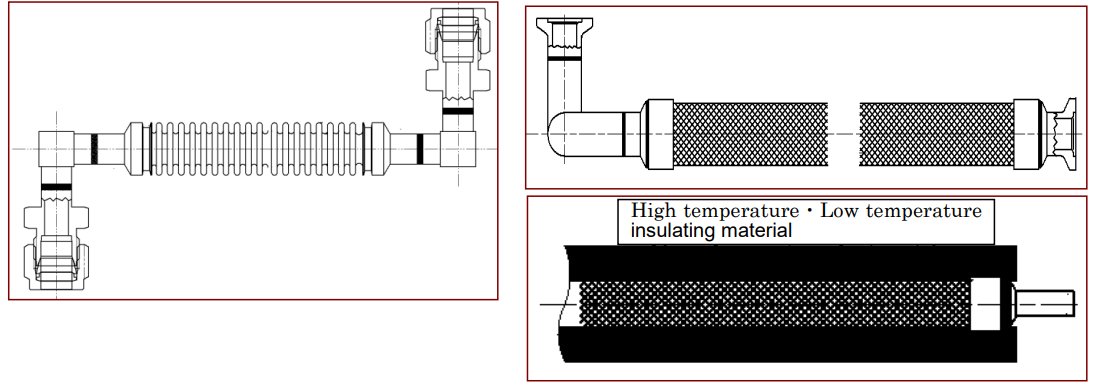

- Metal flex is a flexible hose made of metal with corrugate-formed pipe.

- Using the seam welded pipe made of metal sheet or thin wall pipe, corrugate it by bulge forming and mechanical molding for higher flexibility.

- Besides, a metal braid type to increase the pressure resistance is available.

1. Material of Metal flex

The material of each part of the hose assembly is shown in Table 1 below.

Table 1: Material List

| Parts Name | Material |

|---|---|

| Flex tube | 316L |

| Braid | 304 |

| Adapter | 304, 316, or 316L |

| Collar | 304 |

2. Summary of Type and Size

As the standard of Metal flex, three types are available: flexible tube, semi-soft flex, and fixed bent tube. A summary of types and sizes is shown in Table 2 below.

Table 2: Type and Size

| Type | Flex tube | Micro flex | Semi-flex tube | Fixed bent tube | |||

|---|---|---|---|---|---|---|---|

| Symbol | MHM | MMF | MCF | MHF | |||

| Braid Y or N | Yes | No | No | No | Yes | No | Yes |

| Size | 1/4— 1-1/2 | 1/8—1/4 | 1/4—1/2. 1-1/2. 2 | 1-1/2. 2 | 1/4—1-1/2 | ||

※Regarding the internally polished clean flex, refer to separate 「Clean micro flex」.

3. Types and Dimensions

3.1 Types and dimensions of MHM type are shown in Table-3.

Table-3 MHM Type Flexible hose

| Type | I.D. mm | O.D. mm | Thick mm | Min. bend radius (mm) | Max work press(20°C) Static MPa | Hose Weight g/m | Fitting size Both Ends | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| B-N | B-Y | Fixed | Repeat | B-N | B-Y | B-N | B-Y | ||||

| MHM4 | 6.35 | 10.7 | 12.2 | 0.15 | 23 | 94 | 0.63 | 12.6 | 104 | 208 | 1/4 |

| MHM6 | 9.53 | 16.5 | 18.1 | 0.20 | 25 | 101 | 0.49 | 10.9 | 297 | 446 | 3/8 |

| MHM8 | 12.7 | 19.6 | 21.1 | 0.20 | 30 | 111 | 0.49 | 8.3 | 327 | 490 | 1/2 |

| MHM12 | 19.05 | 29.5 | 31.0 | 0.25 | 43 | 162 | 0.30 | 6.3 | 490 | 758 | 3/4 |

| MHM16 | 25.4 | 37.3 | 38.9 | 0.25 | 53 | 181 | 0.30 | 5.0 | 669 | 1025 | 1 |

| MHM20 | 31.75 | 44.5 | 46.0 | 0.25 | 63 | 200 | 0.30 | 4.5 | 832 | 1307 | 11/4 |

| MHM24 | 38.1 | 52.8 | 54.9 | 0.25 | 79 | 221 | 0.20 | 3.7 | 1218 | 1783 | 11/2 |

※Total length including the fittings is customers’ option.

3.2 Types and dimensions of MMF Micro flex are shown in Table-4.

Table-4 MMF Micro flex

| Type | LD. mm | O.D. mm | Thick mm | Work Press | Fitting size Both Ends |

|---|---|---|---|---|---|

| MMF2-0 | 3.5 | 5 | 0.15 | Vacuum*** MaxO.5MPa | 1/8 |

| MMF3-0 | 4.5 | 7 | 0.15 | 1/4 | |

| MMF4-0 | 5.5 | 8.5 | 0.15 | 1/4 |

※Total length including the fittings is customers’ option.

3.3 Types and dimensions of MCF semi-soft flex are shown in Table-5.

Table-5 MCF Semi-soft flex

| Type | LD. mm | B-N O.D. mm | B-Y O.D. mm | Thick mm | Min bend radius (mm) | Max work press (20°C) MPa | Hose Weight g/m | Fitting size Both ends | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fixed | Repeat | B-N | B-Y | B-N | B-Y | ||||||

| MCF4 | 7.8 | 11.0 | — | 0.15 | 25 | 80 | 0.3 | — | 78 | — | 1/4 |

| MCF6 | 10.0 | 13.5 | — | 0.15 | 25 | 100 | 0.3 | — | 90 | — | 3/8 |

| MCF8 | 12.5 | 16.5 | — | 0.15 | 40 | 120 | 0.3 | — | 108 | — | 1/2 |

| MCF24 | 41.5 | 54.0 | 55.6 | 0.25 | 100 | 270 | 02 | 0.8 | 710 | 1235 | 11/2 |

| MCF32 | 50.5 | 65.0 | 66.6 | 0.25 | 120 | 480 | 0.2 | 0.7 | 850 | 1500 | 2 |

※Total length including the fittings are customers’ option. B-N:none braid, B-Y:with braid

3.4 Types and dimensions of flex for fixed (MHF) are shown in Table-6.

Table-6 MHF Flex for fixed

| Type | I.D. mm | O.D. mm | Thick mm | Min bend radius (mm) | Max work press (20°C) Static MPa | Hose Weight g/m | Fitting size Both Ends | |||

|---|---|---|---|---|---|---|---|---|---|---|

| B-N | B-Y | Fixed | B-N | B-Y | B-N | B-Y | ||||

| MHF4 | 6.35 | 10.5 | 12.2 | 0.15 | 25.4 | 0.63 | 6.3 | 59 | 163 | 1/4 |

| MHF6 | 9.53 | 16.5 | 18.1 | 0.20 | 30.5 | 0.49 | 5.6 | 149 | 253 | 3/8 |

| MHF8 | 12.7 | 19.6 | 21.1 | 0.20 | 38.1 | 0.49 | 4.7 | 163 | 282 | 1/2 |

| MHF12 | 19.05 | 29.5 | 31.0 | 0.25 | 53.3 | 0.30 | 2.7 | 282 | 431 | 3/4 |

| MHF16 | 25.4 | 37.3 | 38.9 | 0.25 | 68.6 | 0.30 | 2.5 | 386 | 624 | 1 |

| MHF20 | 31.75 | 44.5 | 46.0 | 0.25 | 78.8 | 0.21 | 2.0 | 431 | 698 | 11/4 |

| MHF24 | 38.1 | 52.8 | 54.9 | 0.25 | 99.1 | 0.10 | 1.9 | 698 | 1055 | 11/2 |

※Total length including the fittings are customers’ option.

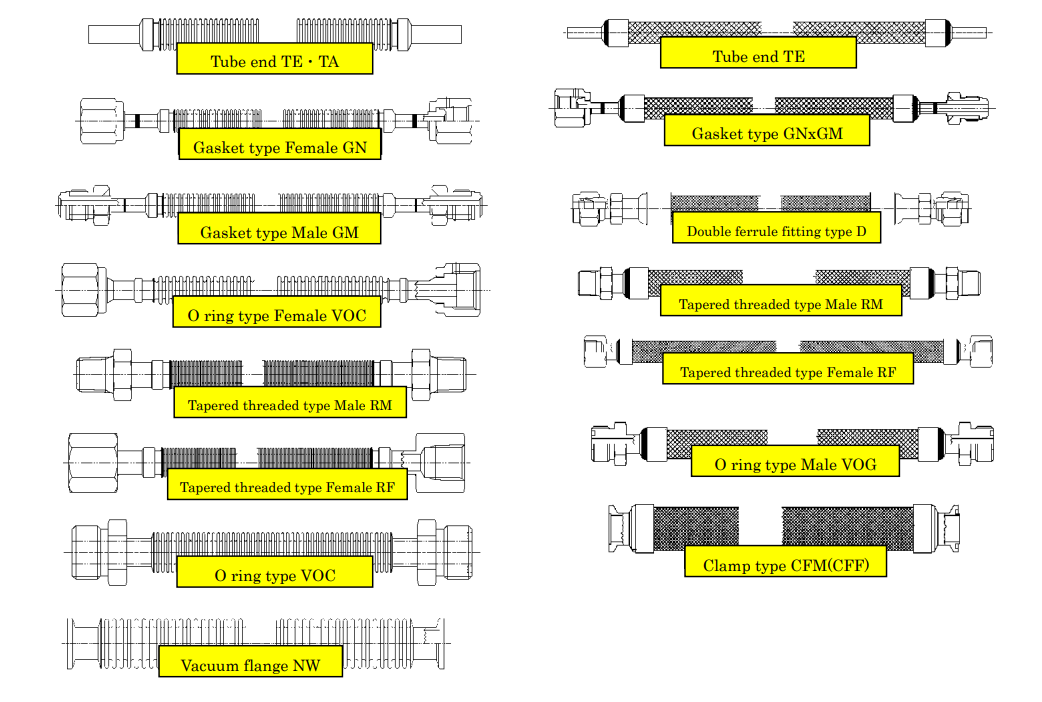

4.Types of adaptor

The connection fittings (Adapter) on Metal flex both ends will be designed in accordance with customers’ piping

system.

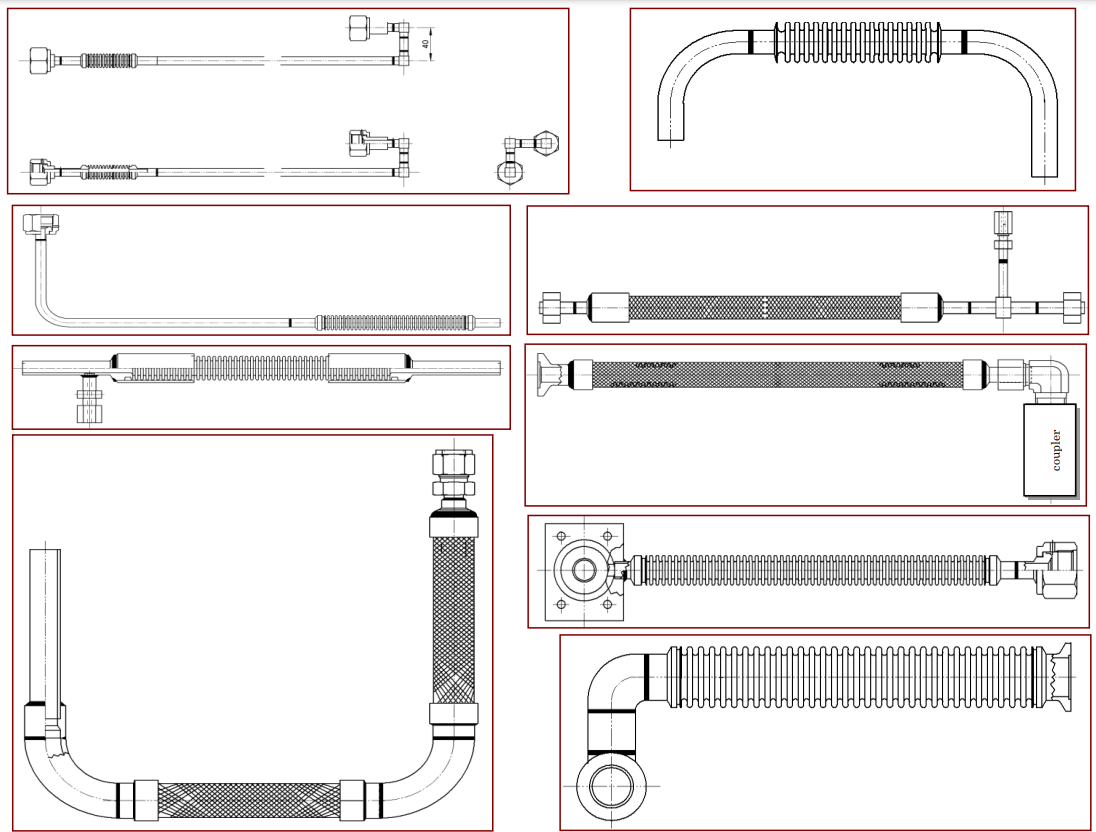

The standard types are shown in Fig-2

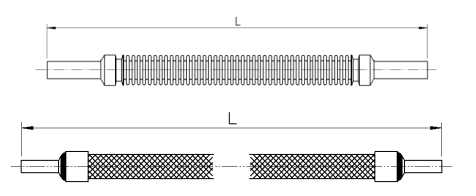

5.Allowable tolerance of total length

Allowable tolerance of total length (L) is shown in Table-7.

| Total Length L (mm) | Tolerance (mm) |

|---|---|

| Less than 300 | ± 10 |

| 300 ~ 500 | ± 15 |

| 500 ~ 1000 | ± 20 |

| 1000 ~ 3000 | ± 30 |

| 3000 ~ 5000 | ± 50 |

| Over 5000 | ± 100 |

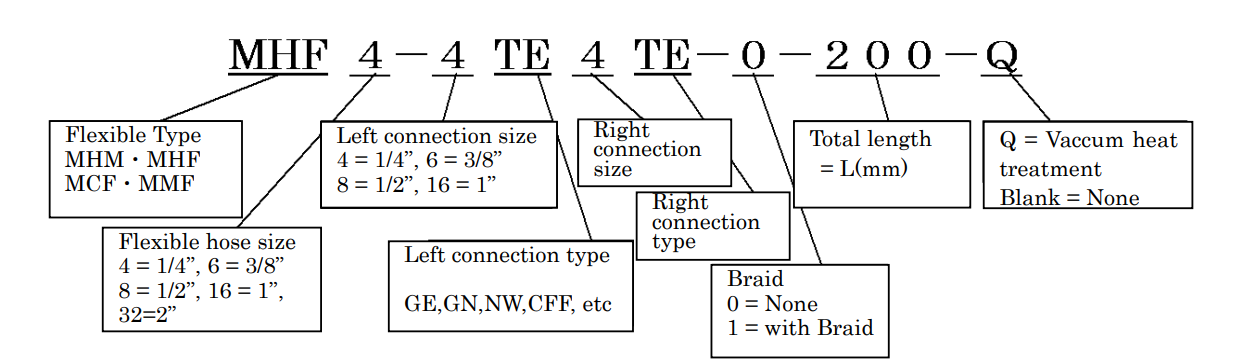

Note: In case of same type on both ends, right side type and size can be omitted. Ex: MHF4-4TE-0-200-Q.

7. He and Airtight inspections (Standard)

Though the inspection will be conducted in accordance with customers’ specification, but following inspection will be done as in-house standard when not specified.

7.1 HE Inspection

As for the Metal flex 「none braid」, He inspection will be done. Criteria for the leak is less 1.0 x 10^-9 Pa·m³/sec

7.2 Airtight Inspection

As for the Metal flex 「with braid」, airtight inspection will be done.

Pressurize with N2 gas up to 1.0MPa and immerse into water bath and hold 3 minutes to check the leakage.

IHARA design and manufacture optimum long fitting (piping system) cooperating with customers.

Please inquire us.

Related Products

-

IHARA WEARLESS SINGLE ACTION PISTON VALVE ADAPTED FOR HEMING SEALER

-

IHARA VNN Series Needle Stop Valves

-

IHARA INF2 Series Inline Filter

-

IHARA NTF Series Clamp Type Metal Gasket Seal Fitting

-

IHARA DVF Series Lightweight and Compact Metal Diaphragm Valve

-

IHARA DVEK Series High Pressure Metal Diaphragm Valve