IHARA SCIENCE CORPORATION

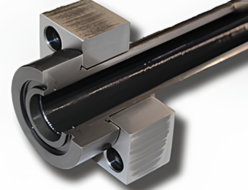

IHARA e-fit Series Weld-less Fitting

Product Made In Japan

Manufacturer: IHARA SCIENCE CORPORATION

Model: e-fit Series

Piping stainless pipes up to 50A now becomes simpler without welding.

No welding required!!

Starting today, you can use it for SUS piping. This is the beginning of SUS piping without welding.

Until Now

So far You have to weld pipe, flange, and clamp joint fitting to install piping. Therefore Preparing welder, Preparing welding equipment, Checking welding conditions, Checking cutting surfaces, Cooling after welding, Removing welding scales, Cleaning, purifying, covering, and sorting out the work place… They prevent immediate piping installation because you need to follow the same procedures even for a simple piping change.

- Need to reduce costs!

- Want to shorten work time!

- Need simpler pipe installation work!

- Want to install pipes without welding!

- Want less human involvement!

- Need simpler pipe changes and adjustments!

From Now

Reduce piping cost to 1/3. You can drastically reduce work time and work man power.

Shorten work process and time to 1/3 of traditional length. You can drastically shorten work process and time thank to elimination of any work associating welding. Also there is no need for tightening a number of bolts paying attention to balance.

Simplify piping works. You can complete piping works simply by inserting pipes and tightening nuts.

Complete piping works without welding. You do not need to prepare any welding technician and any arrangement (welding machine, tool, or material).

Enable easy piping changes or additions. You can change easily simply by switching joint fittings.

Ideal for piping site of fire ban.

⇒ “e fit” joint fittings are products to assist total cost reduction of piping works!

Good Design Award Eco Design Award (Award by Minister of International Trade and Industry)

“e-fit” piping system has received the industry’s first Good Design Award, the Minister of International Trade and Industry Award as an energy-saving piping system.

Pipe Specification

Applicable pipe: SUS304TP-SC or SUS304TP-A of JIS G3459, and SUS304 TP-SC-BA Seamless pipe

Outside diameter tolerance: 15A, 20A: ±0.3mm 25A: ±0.35mm 32A: ±0.43mm 40A: ±0.49mm 50A: ±0.5mm

- The maximum diameter in the case of ovality must not exceed the allowable tolerance described on the left.

Thickness: 1.2mm to Sch10

Hardness: HRB90 or less.

Surface: No harmful defects such as roughness, scratches (especially at the bead part). Thin-walled SUS304 pipes are also available. Please contact us for details.

Major features

- Assist total cost reduction.

- Easy and quick piping work for anybody.

- Enable piping work without welding technician.

- Enable piping with thin wall pipes.

- No deterioration of corrosion resistance due to welding.

- Enable simple piping change and maintenance.

- Reduce electrical power consumption of pumps thanks to less fluid resistance to contribute to energy saving. In addition, make a difference in running cost.

- Ideal for piping at sites of fire ban.

Product specifications

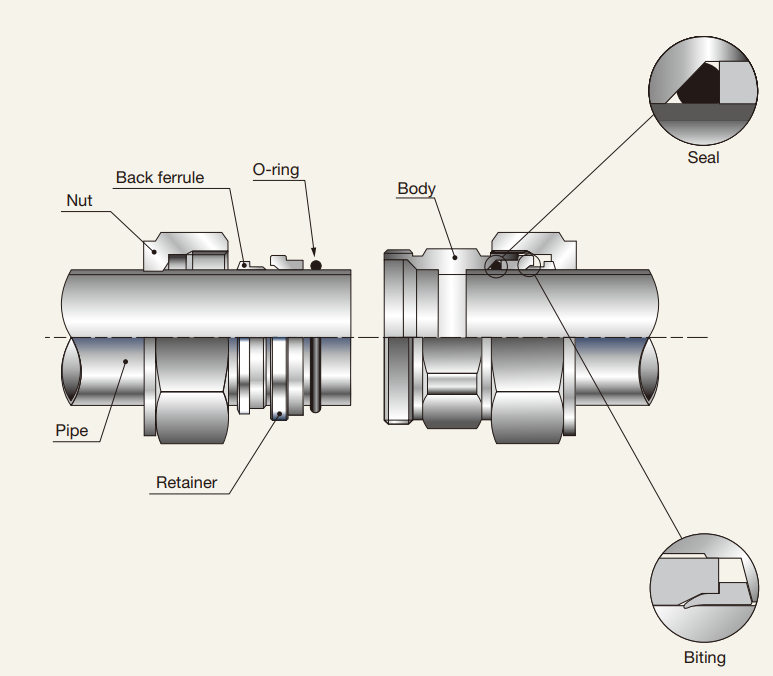

Pressure: VAC to 1Mpa (10kgf/cm²) Temperature: -30°C to 120°C Size: 15A, 20A, 25A, 32A, 40A, 50A Material:

- Joint fitting body: SUS304

- Nut: SUS304

- Back ferrule: SUS304

- Retainer: SUS304

- O-ring: Cold temperature fluoro-rubber

He leakage: 1 x 10^-7Pam³/S or less

*Other specifications are available upon request.

Preparation

Check the cut edges of the pipe for burrs or debris.

(They may damage O-ring, the seal part.)

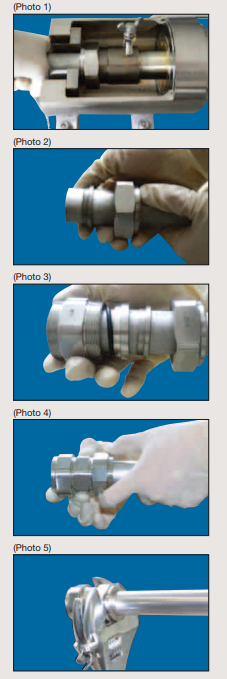

Tightening Work

- Pre-tighten with tightening tool. (Fig. 1)

- Check whether ferrule is tightened. (Fig. 2)

- Check the direction of ferrule. (Fig. 3, Fig. 4)

- Attach retainer and O-ring to the pre-tightened pipe, then install them to the joint fitting body.

- Use wrenches for body and nut to tighten them. Tightening force may sharply increase at a point (abrupt torque rise point).

- Mark this point, then tighten further 60 degrees (1/6 of a turn).

- Tightening work is completed. (Fig. 5)

Retightening

- Draw a matching mark on the nut and body, then disassemble them.

- Retighten them to the matching mark or exceed it a little.

They can be reconnected many times as you desire.