ISHIKAWA

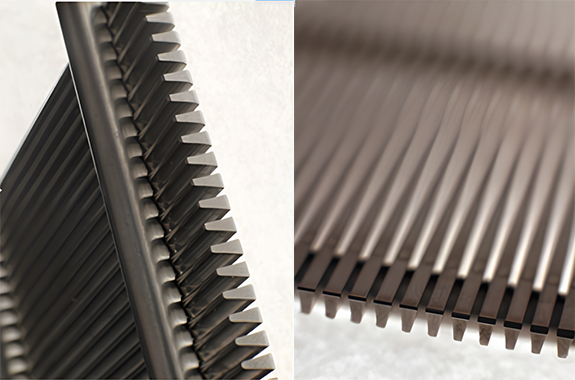

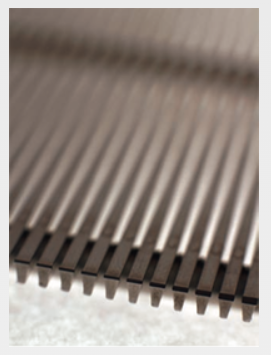

ISHIKAWA Wedge Wire Screen

Made in Japan

Manufacturer: ISHIKAWA WIRE NETTING Co., Ltd.

Wedge Wire Screen Smooth, High Strength, High Precision Pursuing the Potential of Wedge Wire

Wedge Wire Screen Smooth, High Strength, High Precision Pursuing the Potential of Wedge Wire

At Ishikawa Wire Mesh, we manufacture and process products related to wedge wire, along with woven wire mesh. Wedge wire excels in surface smoothness, making it ideal for high-efficiency screening operations with granular materials. Recently, we have improved forming precision, and fine wedge wire with a slit width of less than 200 microns allows for finer operations. We flexibly respond to customer requests, from simple part processing contracts to detailed consideration of machine-specific details and proposing optimal wedge wire for target particles and usage environments. We are also actively developing new applications, such as applying wedge wire as an intermediate function between breaker plates and screens in resin extrusion molding machines.

High-function Screens with High Design Freedom

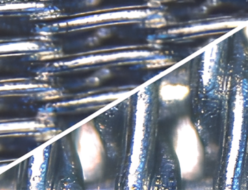

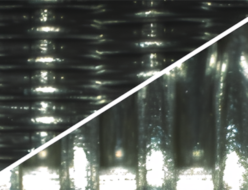

What is Wedge Wire? It mainly involves arranging wedge-shaped irregular wires at equal intervals to form fine slits (slots). Various open rates and strengths are achieved by combining the linear shapes and rods that form the screen. Regardless of industry or location, it can be used for filtration, solid-liquid separation, classification, dehydration, and concentration.

Features of Wedge Wire

- High Strength

- Welding all intersection points ensures high mechanical strength. Depending on the usage environment and material, it may not need to be replaced semi-permanently, reducing running costs.

- High Precision

- The high mechanical strength allows for precise control of passing particle size.

- Excellent Wear Resistance

- Composed of thick wire materials, it excels in wear resistance.

- Fast Processing Speed

- The smooth surface allows processed materials or catalysts to flow smoothly.

- Less Clogging

- The “reverse triangular shape” means that solid materials have fewer contact points and the flared slit is less prone to clogging. Even if it does clog, the high backwash effect makes maintenance easy.

- High Dehydration

- The small contact area when passing through the screen ensures excellent dehydration.

- Easy Maintenance

- Due to its high rigidity and dehydration properties, it has excellent resilience and is easy to maintain.

- Wide Range of Design Flexibility

- With rich processing variations, we can shape it into various forms such as flat, cylindrical, or conical.

Applications

- Dehydration machine elements

- Filters

- Centrifuge parts

- Vibrating sieve machines

- Solid-liquid separation devices

- Strainer elements

- River and seawater intake treatment equipment

- Catalyst and filter media holders such as activated carbon and ion exchange

High Design Freedom

- With rich processability, we can shape it into various forms such as flat, cylindrical (inner or outer wrapped), and conical.

- You can freely select and easily adjust slot sizes, allowing for flexible specification changes.

- In addition to stainless steel, we can also make it from special materials such as titanium, Hastelloy, and Monel.

Related Products

-

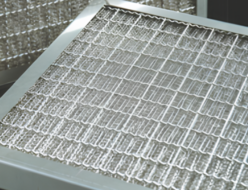

ISHIKAWA Expanded Metal and Processed Products Wire Mesh

-

Ishikawa Insect Screen/Screen Replacement Woven Wire Mesh

-

ISHIKAWA Demisters And Packing Materials

-

ISHIKAWA Twill and Reverse Weave Woven Wire Mesh

-

ISHIKAWA Art Expanded Metal

-

ISHIKAWA Plain Weave and Reverse Plain Weave High-Flow Woven Wire Mesh