ISHIKAWA

ISHIKAWA Electrostatic Separator

Product Made In Japan

Manufacturer: ISHIKAWA WIRE NETTING Co., Ltd.

Model: Electrostatic Separator

Increasing Demand for Reusing Waste Plastics in Consumer Electronics

The demand for reusing waste plastics in consumer electronics and other products is increasing. Traditionally, the general recycling process involved manually dismantling plastics of single materials. However, as the movement to conserve the global environment and effectively utilize limited resources gains momentum, the reuse of crushed scraps containing multiple types of plastics has begun.

To meet the rising demand for recycling, the method of sorting crushed scrap materials has become a crucial point. Ishikawa Wire Mesh offers a new electrostatic separation system.

This system addresses the challenge of electrode collision leading to mixing, which is a drawback of the electrostatic separation method, by adopting circular electrodes. As a result, it enables the high-purity separation of plastics with similar physical properties, such as polypropylene and polyethylene, which are commonly collected through eco-cap movements with PET bottles.

Compared to infrared separation systems, this system can be introduced at about half the cost. The product uses a system invented by Professor Nobuhito Saeki of the Department of Mechanical Engineering, College of Engineering, Shibaura Institute of Technology (joint patent application pending).

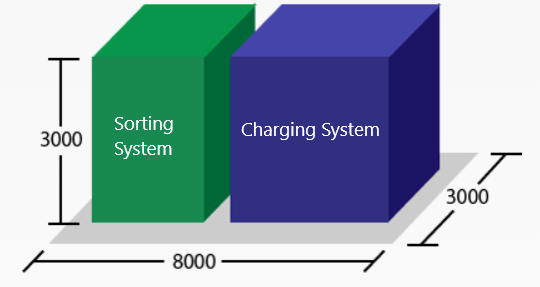

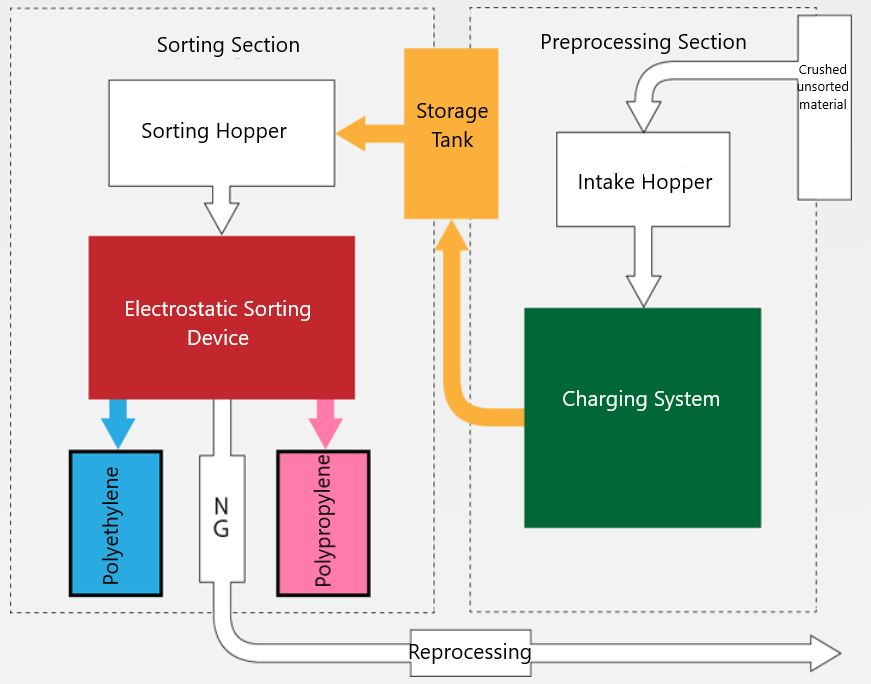

System Overview Diagram

System Overview Diagram

- Preparation of Unsieved Material:

- The material is crushed to 8mm or smaller, washed with water, centrifugally dehydrated, and dried using a dryer.

- Charging Process:

- The prepared material is charged using a charging device.

- Sorting Process:

- The charged material is sent to the sorting section and fed into the electrostatic sorting device via a hopper. Here, the materials are separated into PP (polypropylene) and PE (polyethylene) products.

- Reprocessing of Unsorted Materials:

- Materials that were not successfully sorted are returned to the reprocessing stage for further treatment

Basic Specification Overview

- Delivery Time: Approximately 2 months after placing an order.

- Installation and Support: Our sales representative will assist you with the installation, including identifying installation locations, necessary peripheral devices, and other associated equipment.

| Processing power | 80kg to 120kg per hour for crushed material under 8mm |

|---|---|

| Power source and Power requirements | 3-phase 200V/6kW equivalent |

| Sorting Method and Performance | Electrostatic type, 85% or more *Depends on material conditions |

| Supply Department | Electromagnetic feeder (flow rate control by vibration sensor) |

| Required air Volume and Pressure | 1000L/min (7.5kw compressor with dry function) / 0.5MPa |

| Static Electricity Removal | Airflow Type |