IHARA SCIENCE CORPORATION

IHARA On-Site Flange

Product Made In Japan

Manufacturer: IHARA SCIENCE CORPORATION

Model: On-Site Flange

Features

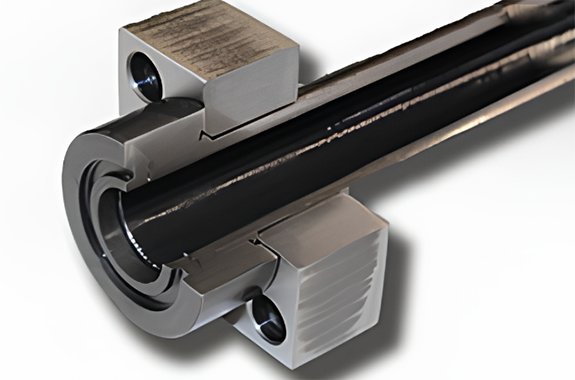

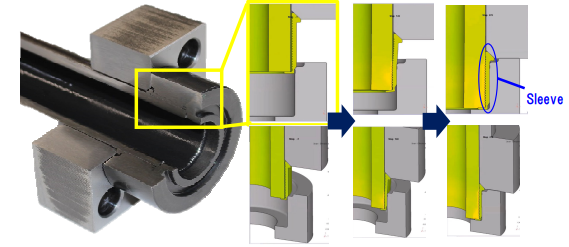

The 『On-Site Flange』 enables piping connections without welding. By utilizing a dedicated tightening device onsite, even individuals without specialized skills can easily and reliably set up connections. No welding work allows

for quick performance of piping maintenance tasks. This product achieves welding-equivalent strength by swaging the sleeve onto the piping. Pre-welding fire prevention measures are unnecessary, and processes like post-weld acid washing are not required. This significantly reduces downtime for facility operation and facilitates easy recovery during troubleshooting.

+ Sleeve securely swages onto the pipe

Pressure testing on Sch160 pipe under more than 140MPa

No leak! No pull-out! No abnormality!

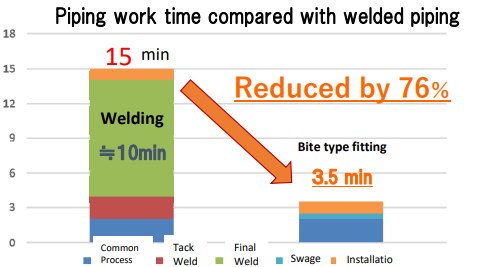

+Significant reduction in piping man-hours !

Basic Specifications

【1. Specifications】

| Rated pressure | 21MPa ※ |

|---|---|

| Size | 15mm (1/2″) ~ 50mm (2″) |

| Temperature | -20℃ ~ 90℃ (O-ring: NBR) |

| Material | Carbon/Stainless steel |

| Fluid | Hydraulic oil, Water |

※ Please contact us if you require specifications above the rated pressure.

2. Primary Materials

| Number | Parts name | Material |

|---|---|---|

| ① | Flange | SS400 equivalent / SUS304 equivalent |

| ② | Brim | C45E4 / SUS304 |

| ③ | Sleeve | Carbon steel / SUS316 |

| ④ | O-ring | NBR |

| Ref. | ⑤ Hex cup bolt | SCM435 / SUS304 equivalent |

| Ref. | ⑥ Washer | Carbon steel / SUS304 equivalent |

| Ref. | ⑦ Hex nut | Carbon steel / SUS304 equivalent |

【3.Applicable pipe standards (for reference)】

(1) JIS G 3454 Carbon steel pipes for general service: STPG 370

(2) JIS G 3455 Carbon steel pipes for high pressure service: STS 370

(3) JIS G 3456 Carbon steel pipes for high temperature service: STPT 370

(4)SUS 304TP and SUS 316TP specified in stainless steel piping for JIS 3459 piping

Table On-Site Flange Applicable pipe outer diameter dimensions and tolerances※

| Nominal | pipe outer dia (/) (mm) | tolerances | |

|---|---|---|---|

| A | B | ||

| 15mm | (1/2″) | 21.7 | ± 0.3 mm |

| 20mm | (3/4″) | 27.2 | ± 0.3 mm |

| 25mm | (1″) | 34 | ± 0.3 mm |

| 32mm | (1 • 1/4″) | 42.7 | ±0.8% |

| 40mm | (1 • 1/2″) | 48.6 | ±0.8% |

| 50mm | (2″) | 60.5 | ± 0.3 mm |

Tolerances are in accordance with JIS G3454 Outer Diameter Tolerances for Cold-Finished Seamless Steel Pipes.

However, 50mm (2”) alone has strict allowable tolerances.

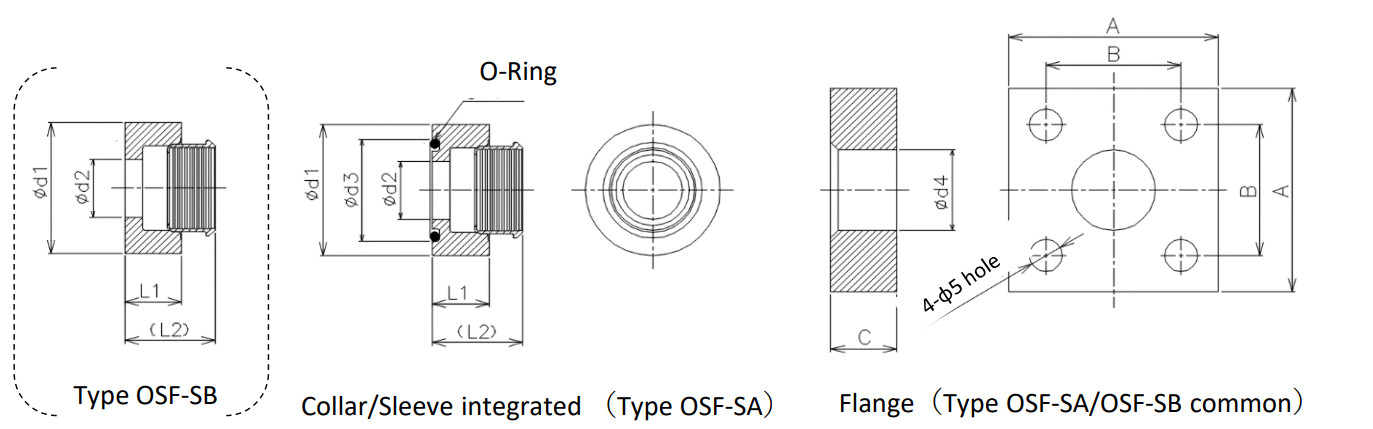

OSF‐SA・OSF‐SB Dimension Table

Unit: mm

| Nominal Size | Pipe Size | A | A(min) | A(max) | B | C | d1 | d2 | d3 | d4 | d5 | L1 | L2 | O ring | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bolt | |||||||||||||||

| OSF-SA-15 /OSF-SB-15 | 15A (1/2B) | 54 | 53 | 58 | 36 | 22 | 40 | 16 | 30 | 22.3 | 11 | 19 | 30.4 | G25 | MIO |

| OSF-SA-20 /OSF-SB-20 | 20A (3/4B) | 58 | 57 | 62 | 40 | 22 | 45 | 20 | 35 | 27.8 | 11 | 19 | 29.7 | G30 | MIO |

| OSF-SA-25 / OSF-SB-25 | 25A (IB) | 68 | 67 | 73 | 48 | 28 | 55 | 25 | 40 | 34.6 | 13 | 23 | 36.4 | G35 | M12 |

| OSF-SA-32 /OSF-SB-32 | 32A (1 • 1/4B) | 76 | 73.5 | 81 | 56 | 28 | 65 | 31.5 | 45 | 43.3 | 13 | 31 | 47.7 | G40 | M12 |

| OSF-SA-40 / OSF-SB-40 | 40A (1 • 1/2B) | 92 | 88.5 | 98 | 65 | 36 | 72 | 37.5 | 55 | 49.2 | 18 | 31 | 47.7 | G50 | M16 |

| OSF-SA-50 / OSF-SB-50 | 50A (2B) | 100 | 98 | 106 | 73 | 36 | 84 | 47.5 | 65 | 61 | 18 | 37.5 | 60 | G60 | M16 |

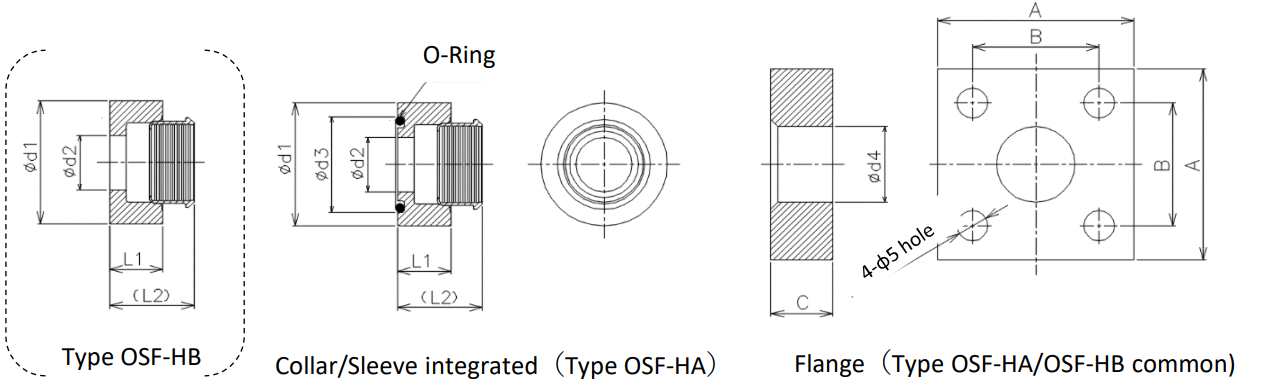

OSF‐HA・OSF‐HB Dimension Table

| Nominal Size | Pipe Size | A | A(min) | A(max) | B | C | dl | d2 | d3 | d4 | d5 | LI | (L2) | 0 ring | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bolt | |||||||||||||||

| OSF-HA-15 / OSF-HB-15 | 15A (1/2B) | 63 | 62 | 67 | 40 | 22 | 40 | 16 | 30 | 22.3 | 11 | 19 | 30.4 | G25 | MIO |

| OSF-HA-20 / OSF-HB-20 | 20A (3/4B) | 68 | 67 | 72 | 45 | 22 | 45 | 20 | 35 | 27.8 | 11 | 19 | 29.7 | G30 | MIO |

| OSF-HA-25 /OSF-HB-25 | 25A (IB) | 80 | 78.5 | 85 | 53 | 28 | 55 | 25 | 40 | 34.6 | 13 | 23 | 36.4 | G35 | M12 |

| OSF-HA-32 /OSF-HB-32 | 32A (1 • 1/4B) | 90 | 88.5 | 95 | 63 | 28 | 65 | 31.5 | 45 | 43.3 | 13 | 31 | 47.7 | G40 | M12 |

| OSF-HA-40 / OSF-HB-40 | 40A (1 • 1/2B) | 100 | 98 | 106 | 70 | 36 | 72 | 37.5 | 55 | 49.2 | 18 | 31 | 47.7 | G50 | M16 |

| OSF-HA-50 / OSF-HB-50 | 50A (2B) | 112 | 108 | 118 | 80 | 36 | 84 | 47.5 | 65 | 61 | 18 | 37.5 | 60 | G60 | M16 |

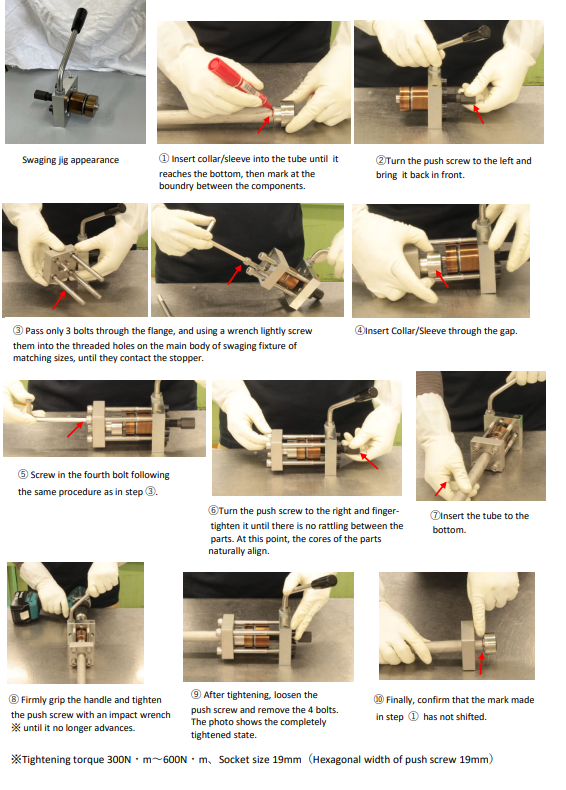

Swaging jigs and procedures for sizes 15A(1/2B)and 20A(3/4B)

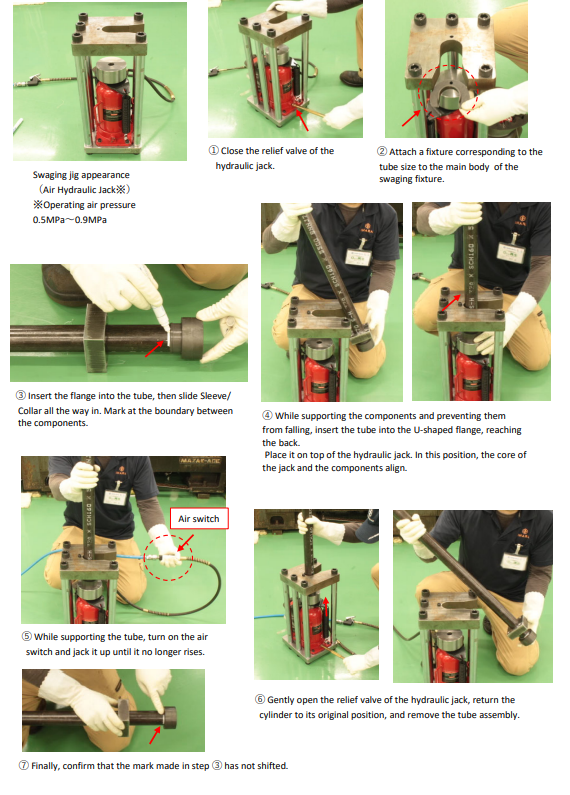

Swaging jigs and procedures for sizes 5A(1/2B)〜50A(2B)

Related Products

-

IHARA DVKA Series Diaphragm Valve For High Pressure Service

-

IHARA VBM Series Fine Metering Valves

-

IHARA ISTEC Series Clean Tube Cutter for Stainless Tubes & Pipes

-

IHARA INF2 Series Inline Filter

-

IHARA 17 Series 17.5MPa Panel Mounted Compact Ball Valve

-

IHARA DVEK Series High Pressure Metal Diaphragm Valve