IHARA SCIENCE CORPORATION

IHARA NTF Series Clamp Type Metal Gasket Seal Fitting

Product Made In Japan

Manufacturer: IHARA SCIENCE CORPORATION

Model: NTF Series

Developed a new concept of Metal Gasket Seal Fitting (NTF) that realized Particle free.

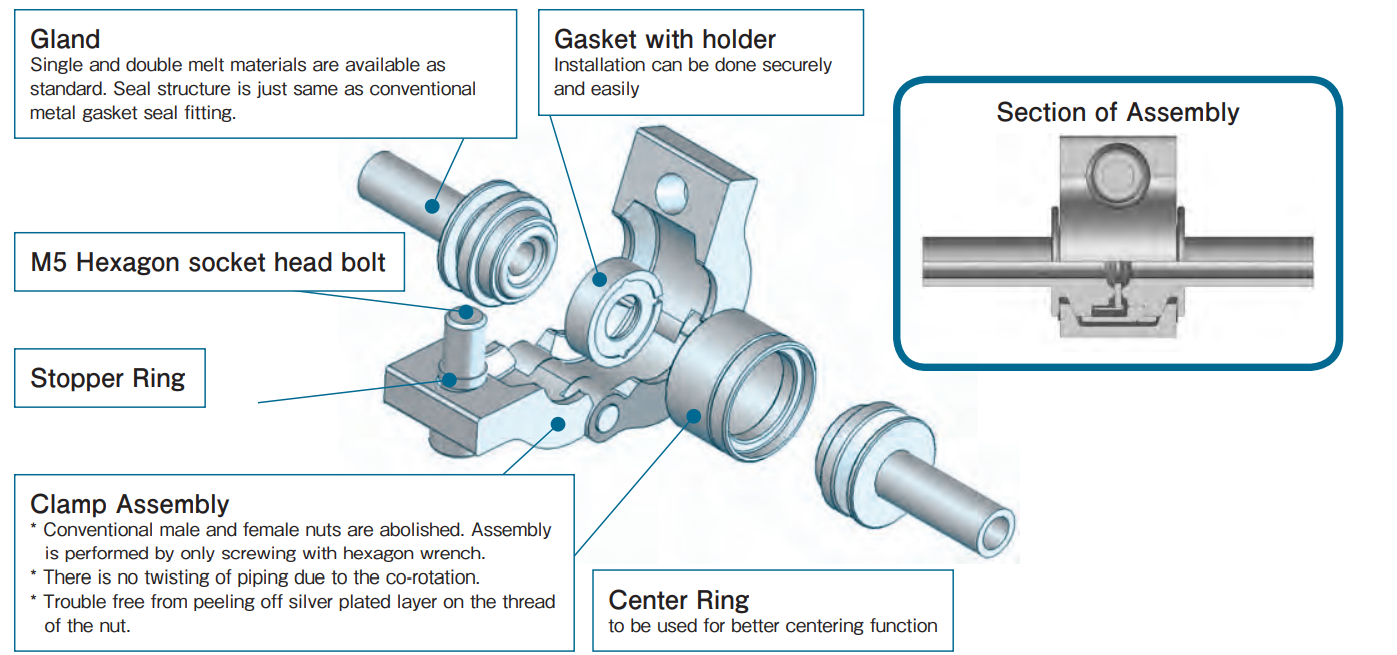

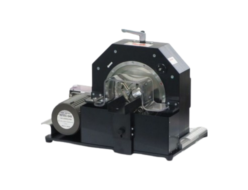

Standard Assembly

◆Features

The weak point of conventional metal gasket seal fitting are ” Twisting of the piping and contamination of inside piping due to the generation of particles during nut tightening. NTF fitting is innovative clamp type metal gasket fittong that solved nut troubles.

□Through tightening a screw, it can generate same tightening force as a convential.

(Design and handle with care as NTF is inferior to the conventional against the abnormal force from outside)

□NTF fitting is suitable for the integration as the assembly work can be completed within a narrow space.

□Sealing is an exactly same structure as the conventional in the shape and dimension.

□NTF fitting is Rohs compliant product.

◆Specifications

Material Used

| Parts Name | Material |

|---|---|

| Gland Plug | SUS316L |

| Center Ring | SUS316 |

| Clamp Assembly | SUS630 |

| Gasket / Holder | Ni, SUS316LW double melted / SUS316 |

Working Pressure and Temperature

| Working Pressure | |

|---|---|

| Negative | VAC ~ 0 Pa |

| Positive | 0 ~ 1 MPa |

| Range of Working Temperature | |

|---|---|

| Range of Working Temperature | -60°C ~ 250°C |

Assembly Procedure

1. Mount Gasket with holder on the left hand Gland in the above figure.

2. Insert the left hand gland into the Center ring (side of no identification groove)

3. Insert the other side gland into the Center ring and confront with both gland faces carefully so that do not damage the gasket.

4. In case of using torque wrench

Cover the NTF Clamp assembly and tighten the screw up to 3 N・m torque.

Secure if the clamp is correctly assembled (bending or diagonal setting of the clamp are prohibited).

5. In case of using hex-wrench

Cover the NTF Clamp assembly and tighten the screw up to the stopper ring touch the clamp.

As the excess tightening might damage the clamp, stop tightening when the stopper ring touch the clamp. ( Be careful of the excess tightening, as the hex-wrench tightening may exceed a little more than a torque wrench.)

Types

To ensure that our customers are satisfied with the applications and cost performance of our products, we also offer the three types beyond our standard combination.

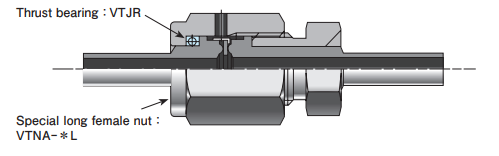

①Thrust bearing inserted type

Smooth tightening keeps tightening torque low for the female nut. Useful for preventing co-rotation with the gland, and minimal twisting during piping work.

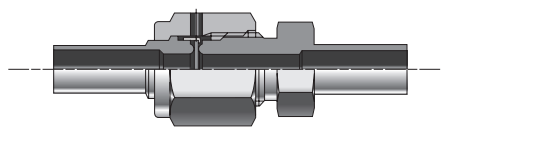

②Compact (High flow) type Very compact, but realized high flow.

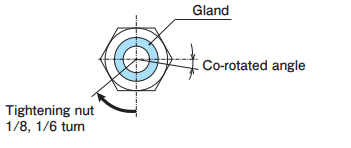

Reference: Data of gland co-rotation (in-house test data)

| Size | Standard | Thrust washer/bearing inserted |

|---|---|---|

| Tightened 1/8 turn | Tightened 1/6 turn | |

| 1/4″ | 2° ~ 2°30′ | 0°18′ ~ 0°30′ |

| 1/2″ | 2°30′ ~ 3° | 0°30′ ~ 1° |

Related Products

-

IHARA CVG series Bellows Valve

-

IHARA e Series Stainless Steel Fitting For Polymer And Vinyl Tubes

-

IHARA DVEK Series High Pressure Metal Diaphragm Valve

-

IHARA CVB & CVF Series Bellows Valve

-

IHARA ISTEC Series Clean Tube Cutter for Stainless Tubes & Pipes

-

IHARA VB* Series Needle Stop Valves Out Side Screw Type