Fukudaco, Japan

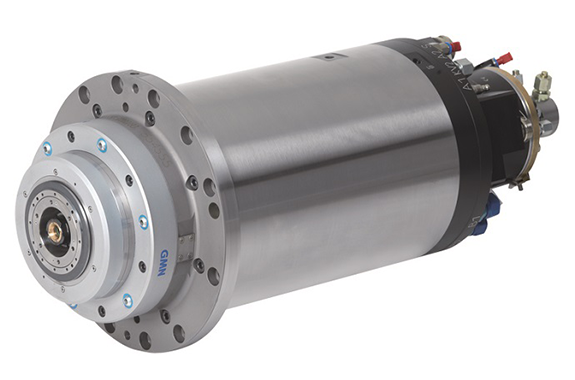

Fukudaco GMN High-Frequency Spindle (Automatic Tool Changer)

Manufacturer: Fukudaco

Model: GMN

Overview

Applications of GMN high-frequency spindles

- Cutting tool spindles

- Machining centers

- Grinding

- Combined use with cutting rotary tools and lathe fixed tools

Features of GMN high-frequency spindles

- High speed and rigidity primarily due to in-house manufactured bearings

- Custom-made solutions available

- Incorporation of the latest technologies through joint projects with research institutions and universities

- Predictive maintenance enabled by sensors designed for automation

- Compact design suitable for 5-axis head installation

Key Specifications and Features by Series

| Series name | HC | HCS | UHC | HCT | H.G.C. | HGT |

|---|---|---|---|---|---|---|

| Housing diameter [φmm] | 80~380 | 120 | 120 to 400 | 80–400 | 120 to 400 | |

| Maximum rotation speed [min -1 ] | 75,000 | 90,000 | 40,000 | 30,000 | ||

| Maximum power output (S1) [kW] | 150 | 15 | 150 | 80 | ||

| Maximum torque (S1) [Nm] | 1,750 | 6 | 1,000 | 300 | ||

| Tool Interface | HSK-E/-F | HSK-A/-B/-E/-F/-T, BT, BBT, PSC | HSK-E | HSK-A/-B/-E/-F/-T, BT, BBT, PSC | ||

| Shaft lock mechanism | × | × | × | ◎ | × | ◎ |

| Encoder | × | ◎ | ◎ | ◎ | ◎ | ◎ |

| Applications | Mainly grinding | Mainly cutting | Mainly high-speed cutting | Mainly cutting and turning | Mainly for grinding and special purposes | Mainly for grinding, turning, special applications |