HISAKA WORKS.LTD.

HISAKA Plate Heat Exchangers

Product Made In Japan

Manufacturer: HISAKA WORK LIMITED

Model: Heat Exchangers Series

Using plate-type heat exchangers as HISAKA core technology, the company provides thermal solutions to our customers worldwide.

Use it “surely.” “more.”

Use it “longer” into the future.

HISAKA continues to supply reliable plate heat exchangers.

HISAKA WORKS, LTD. is the largest plate heat exchanger manufacturer in Asia.

Manufacturing plate heat exchangers are used in applications such as heating, cooling, sterilization, pasteurization, heat recovery, and condensation in various industrial processes for chemicals, food, air conditioning, marine, pulp and paper, steel/metal, and automobile and related. The HISAKA contributes to the effective use of resources and the improved efficiency of production facilities. This company is also actively engaged in overseas expansion. It have established networks in Malaysia, Thailand, Singapore, China, South Korea, Indonesia, Vietnam, the Philippines, and Saudi Arabia, and also provides technology to ARSOPI THERMAL (Portugal).

Structure of Plate Heat Exchanger

Since HISAKA deliveredr first domestically-produced device in 1953, HISAKA plate heat exchangers have been used in all kinds of industries as compact heat exchangers with maximum efficiency. In order to meet more diverse and more sophisticated needs, HISAKA have arranged a rich variety of models, from small models of 0.18 m²/unit to large models up to 3,400 m²/unit.

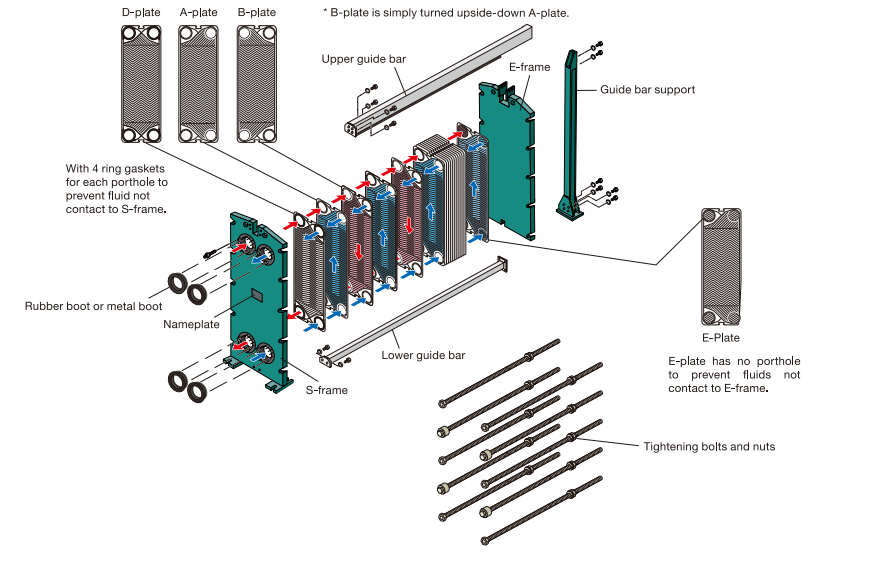

Basic Structure

Heat transfer plates are made by pressing thin sheets of corrosion-resistant metal such as stainless steel or titanium, then set them with seal gaskets and hang and pile them on the guide bar. Then, plates are tightened with bolts between the fixed frame and the movable frame. Here, there is a certain gap between the heat transfer plates that allows liquid to flow. The liquid inlets and outlets are in the fixed frame or the movable frame.

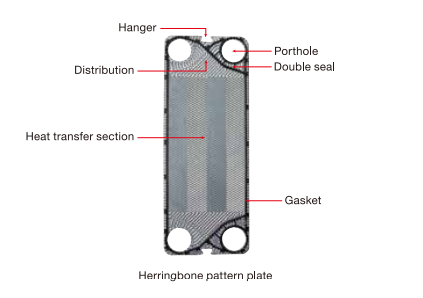

Heat Transfer Plate

Each heat transfer plate is corrugated to various patterns to increase its strength and surface area. Furthermore, the corrugation makes high turbulence and thereby achieves high heat transfer coefficient. Portholes are formed in the plate’s four corners. The gasket is set into the groove around the plate edge to seal in the fluid.

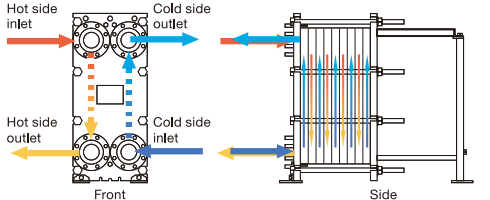

Flow Chanel of Fluid

(PHE)

Standard Operational Data

Processing capacity: 0.1 m³/h to 7,300 m³/h

Working pressure: max. 4.0 MPaG

Working temperature: max. 180°C

Heat transfer area: 0.18 m²/unit to 3,400 m²/unit

Plate material:

- Stainless steel: 304, 316, 315J1, 317, Etc.

- Titanium: TP270, TP270-Pd

- High nickel alloy: C-276, C-22, B, G

- Nickel: NNCP, NLCP

- Other: Domestic and international standard materials

Gasket materials:

- NBR, IIR, EPDM, FPM, Silicon,

- TCG (PTFE cushion gasket)

The above data varies depending on the model, material, plate thickness, and operating specifications.

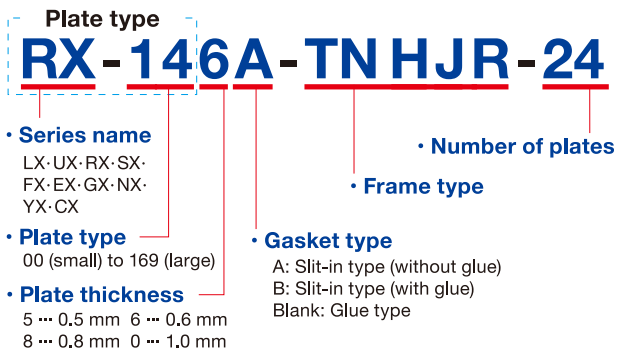

PHE Model Numbers

The plate type, thickness, and number, and the frame type for HISAKA PHEs are indicated as below.

Related Products

REQUEST QUOTATION

PAYMENT

MAKER

TOOLS & EQUIPMENT

Lifting

Eagle Clamp | Eagle Jack | Elephant | Endo Kogyo

Kanetec | Jung | KITO

Kondotec | Miki Netsuren | Sanei Seiki

Hand Tools

Bix | Miyakawa | Nakatani Kikai | Ogura |

Super Tool | TONE | Yutani

Tape

Kamoi | Kikusui | Nirei | Teraoka

Measurement

Hasegawa | Kawaki | Kett | KGK | Line Seiki | Nagano Keiki

Niigata Seiki | Obishi Keiki | RSK | Ryoden Shonan | Sanko

Showa Seisakusho | Showa Sokki

Safety Tools

Fujii Denko | Shigematsu | Titan

Welding

Asahi Weldex | Daihen | Koike | Nissan Tanaka

Other Tools

Hammer Caster | Matsuda Seiki | Sanritsu

Sanyutec | Toyo Kensetsu Kohki

Yamari

PLANT FACILITIES

Facilities

Acokk | Bunkaboeki | Horiuchi | Konan | Murakoshi

Murakoshi Industries | Nesstech | Nikkin Flux

NFK | Organo | Taiyo Parker

Pump

Honda Kiko | Kyowa | Musashino

Valve

Astam | Kyowa Iron | Nachi | Nippon Daiya | Sawada

Wasino Kiki | Yoshitake

Electricity

Asahi Bagnal | Kokosha | U_RD

CONSTRUCTION

Concrete Work

EXEN | Japan Life | Mikasa | Taiheiyo

High Tension Bolt

Dong Ah | KPF | Nippon Fastener

Bolt & Nut & Washer

Hard Lock | Mori Kozai

Nakaumi | Otani | Toneji

STEEL MATERIAL

Steel & other Material

Dongil | JIS Standard | DSR | Winoa IKK