Japan, Orientalmotor

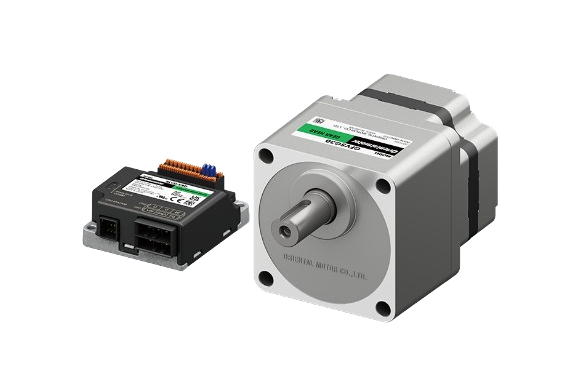

Orientalmotor Motor Only Brushless Motors

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Product name: Motor Only Brushless Motors

Product Line

Compact, lightweight, and highly efficient brushless motor. The 24 VDC Type product line has rated output power of 15 W~100 W.

Round Shaft Type

| Output Shaft Type | Frame Size [mm] | Output Power [W] | Mass [kg] | IP classification | Product Name | List Price |

|---|---|---|---|---|---|---|

| 42 | 15 | 0.25 | IP40 | BLHM015K-A | 13,200 JPY |

| 30 | 0.27 | IP40 | BLM030DHK-A | 12,900 JPY* | ||

| 60 | 30 | 0.5 | IP40 | BLHM230K-A | 14,300JPY | |

| IP65 | BLHM230KC-A | 15,200JPY | ||||

| 50 | 0.47 | IP40 | BLM250DHK-A | 14,000 JPY* | ||

| 80 | 50 | 0.8 | IP40 | BLHM450K-A | 15,400 JPY | |

| IP65 | BLHM450KC-A | 16,300 JPY | ||||

| 90 | 100 | 1.4 | IP40 | BLHM5100K-A | 18,700 JPY | |

| IP65 | BLHM5100KC-A | 19,600 JPY |

*A motor separate connection cable is required.

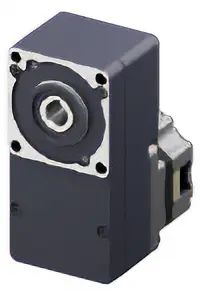

Combination With Gearhead

High-Strength, Low-Noise Gearhead for Increased Torque

Various types of high-strength, low-noise dedicated gearheads are available for brushless motors.

Utilization of the gearhead produces a large torque that cannot be generated by the motor alone, enabling a large-inertia drive.

In addition, the speed fluctuation in response to changes in load can be minimized due to the deceleration effect of the gearheads.

| Gearhead Type | Parallel Shaft Gearhead GFS Gearhead | CS Geared Motor | Hollow Shaft Flat Gearhead FR Gearhead |

|---|---|---|---|

| External View |  |  |  |

| Features | Wide range of gear ratios Rated life 10000 hours*1 | Increased radial and axial load Center shaft Rated life of 10000 hours | Space saving, cost savingUnsaturated permissible torque Rated life of 10000 hours |

| Motor Output Power | 15, 30, 50, 100 W | 30, 50 W | 30, 50, 100 W |

| Gear Ratio | 5, 10, 15, 20, 30, 50, 100, 200*2 | 5, 10, 15, 20 | 5, 10, 15, 20, 30, 50, 100, 200 |

*1 The 15 W products have a rated life of 5000 hours.

- *2 The gear ratio of 15 W products is 5~100.

Motor/Gearhead Product Line

A number indicating the gear ratio is specified where the box □ is located in the product name.

| Output Shaft Type | Frame Size [mm] | Output Power [W] | Mass [kg] | IP classification | Product Name (Motor/Gearhead) |

|---|---|---|---|---|---|

GFS Gearhead  | 42 | 15 | 0.5 | IP40 | BLHM015K-□*1 |

| 60 | 30 | 1.0 | IP40 | BLHM230K-GFS /GFS2G□ | |

| IP65 | BLHM230KC-GFS /GFS2G□ | ||||

| 80 | 50 | 1.8 | IP40 | BLHM450K-GFS /GFS4G□ | |

| IP65 | BLHM450KC-GFS /GFS4G□ | ||||

| 90 | 100 | 2.9 | IP40 | BLHM5100K-GFS /GFS5G□ | |

| IP65 | BLHM5100K-GFS /GFS5G□ | ||||

| 42 | 30 | 0.44 | IP40 | BLM030DHK-□CS |

| 60 | 50 | 0.87 | IP40 | BLM250DHK-□CS | |

FR Gearhead  | 60 | 30 | 1.3 | IP40 | BLHM230K-GFS /GFS2G□FR |

| IP65 | BLHM230KC-GFS /GFS2G□FR | ||||

| 80 | 50 | 2.4 | IP40 | BLHM450K-GFS /GFS4G□FR | |

| IP65 | BLHM450KC-GFS /GFS4G□FR | ||||

| 90 | 100 | 3.6 | IP40 | BLHM5100K-GFS /GFS2G□FR | |

| IP65 | BLHM5100K-GFS /GFS2G□FR |

*1The 15 W product is a geared motor in which the motor and gearhead are integrated.

*2A separate motor connection cable is required.

Brushless Motor Features

Structure

Oriental Motor brushless motors are of the inner rotor type.

The rotor is inside the stator, and permanent magnets are placed on its surface. Since the rotor is thin and has a small inertia, it has high responsiveness during acceleration and deceleration.

Also, the stator is located close to the surface of the motor, making it a compact motor with good heat dissipation and high output power.

Power Performance

Torque Curve Has Small Speed Fluctuation

Since the torque design focuses on the practical range from mid to low speeds, it is characterized by low fluctuations in speed relative to load changes.

High-Speed and Low-Speed High-Torque Ranges Can Also be Utilized

In combination with customer-designed drivers, the high-speed range and low-speed, high-torque operating range can also be utilized.

(Limited Duty Region)

Contributes to increased performance of applications.

High Torque Generated per Unit of Current

The large torque constant design allows a small motor to drive a high load.

It can also be used with leeway in areas where torque is capped by current limits due to power supply or circuit constraints.

Reliability and Low Vibration

Low Cogging Torque

Low cogging torque is achieved by using the correct combination of rotor poles and stator slots.

Smooth rotation with reduced vibration and uneven rotation at low speeds.

High Resistance to Eccentric Load

Creep resistance is improved by attaching an O-ring to the bearing’s outer ring. It can be used safely for fan and pump applications.

(Applicable to some round shaft type models where the load is directly attached to the motor’s rotating shaft)

Vibration Suppression Using Rotor Balancing

Rotor imbalance is suppressed by inspection and adjustment. Smooth rotation with reduced vibration and uneven rotation in the mid to high-speed range.

Related Products

-

Saitama Seiki U-TOOL U-585 8″ Angle Polisher

-

Watanabe CTL-10 Small Split CT Accessory With Primary Side Rating 5/30/50A

-

NPK Angle Grinders

-

SAKUSAKU 4SS-30D 2.0S Carbide Square End Mill 4-Flute

-

KONAN MAGSTER ⅡF MVS2F-08 5 Port Solenoid Valves Gasket-connected Type 2 Positions Return

-

YOSHITAKE GD-27BP Pressure Reducing Valve – Water