Fukudaco, Japan

Fukudaco B-Safe Spindle Monitoring System

Manufacturer: Fukudaco

Overview

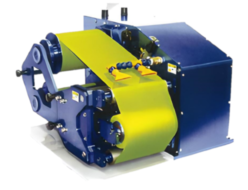

B-Safe is optimized for diagnosing spindles and other machine tools through vibration and temperature condition analysis. By directly attaching miniaturized sensors to measurement points, various abnormalities can be monitored in real-time. The latest version, “X,” enhances predictive maintenance capabilities, further reducing machine downtime.

Applications

- Monitoring the condition of machine tool spindles

- Abnormality detection

- Abnormality recording

- Operational statistics

- Preventive maintenance

- Predictive maintenance

Features

- Real-time monitoring of XYZ 3-axis acceleration, high-resolution vibration waveforms in one axis, and temperature.

- Stores up to 2000 timestamped alarm histories in the sensor’s built-in memory.

- Automatically records vibration acceleration waveforms 5 seconds before and after detecting a collision.

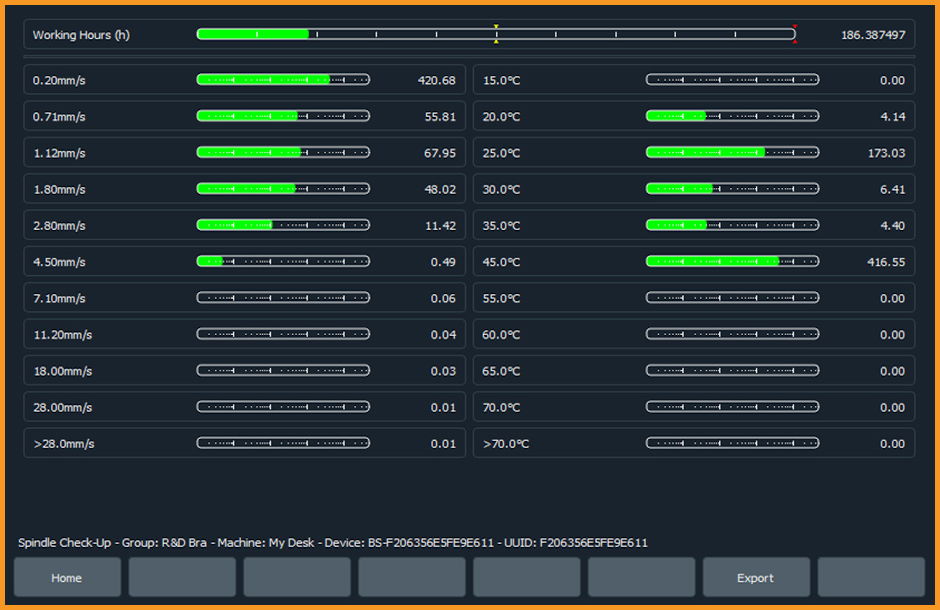

- The operational statistics function proposes optimal maintenance cycles.

Innovative Solutions

3-Axis Acceleration Sensor with Hybrid MEMS Technology

- Micro Electro Mechanical System (MEMS): A microdevice integrating IC and micromachine technologies.

High-Frequency Vibration and Temperature Analysis

- Achieved through the integration of piezo elements and temperature sensors.

Standalone Operation and Real-Time Logging

- Enabled by integrating memory into the sensor body.

- Records and stores valuable data for analyzing collisions, imbalance, overload, abnormal work cycles, tool wear and breakage, and bearing behavior.

Multi-Platform Software

Advanced HMI Software Integration

Seamlessly integrates with B-Safe sensors to enable remote monitoring of the production line.

Real-Time Connectivity

Multi-platform software supports continuous connection, allowing extensive data retrieval from operating machines.

Dashboard

The B-Safe HMI (Human-Machine Interface) is designed with simplicity and intuitiveness in mind, ensuring all information is easily understandable at a glance.

In the latest version, the software supports the management of more sensors, enabling simultaneous monitoring and control of multiple machines.

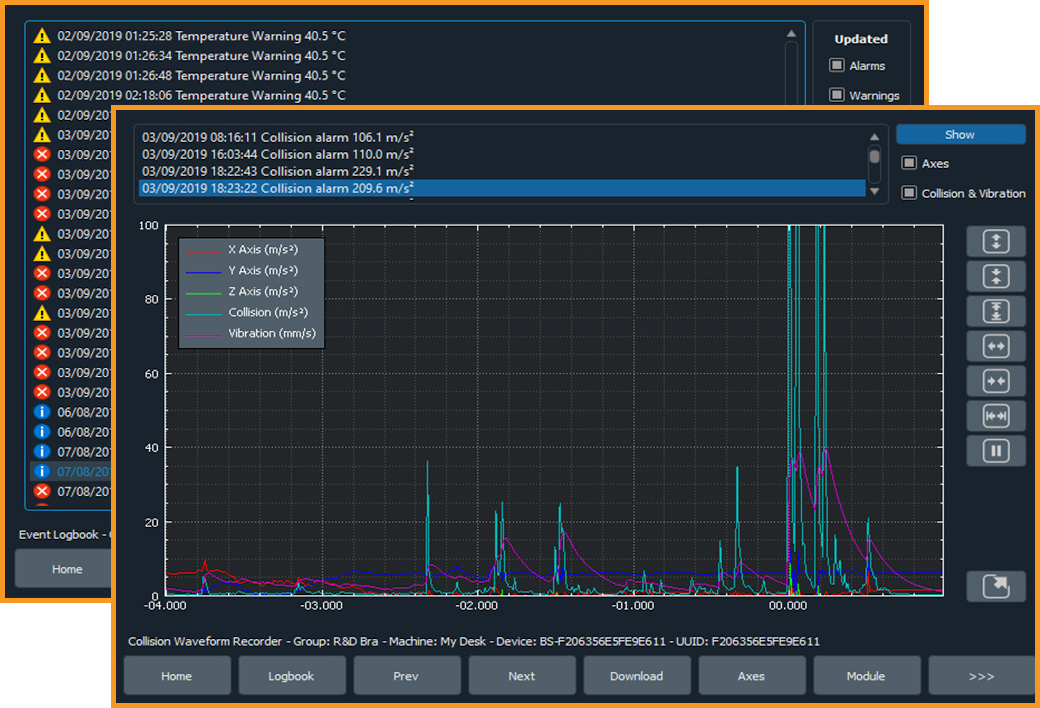

Event Log

The event log feature provides intuitive infographics, allowing instant understanding of all activities, including abnormal alarms, warnings, checkups, and power shutdowns.

When the system detects a spindle collision, it records detailed vibration waveforms 4 seconds before and 1 second after the event, enabling thorough post-incident investigation.

Real-Time Data

All sensor data (temperature sensors, 3-axis MEMS sensors, high-frequency 1-axis piezo sensors) can be monitored in real-time using the B-Safe HMI software.

The B-Safe system manages data autonomously, allowing you to export measurement data in real-time or at any desired moment.

Trends

The system features weighting and threshold customization for statistical or trend data, catering to diverse needs.

By using the B-Safe cloud application, you can remotely access functions for monitoring and evaluating spindle conditions.

Fingerprint

This predictive maintenance feature, known as “Fingerprint,” records and learns the unique operational tendencies of each spindle, akin to a fingerprint.

By continuously accumulating the machine’s vibration profiles from daily routine operations (such as daily check recipes), it visualizes early warning signals of potential failures from the shaft or bearings as alerts.

Specification

| Sensor dimensions | M12 x 1.0 – L41 mm (connector type) M12 x 1.0 – L32 mm (direct cable type A) M16 x 1.5 – L22 mm (direct cable type B) |

| Cable length | 5m (standard)* * Various extension adapters/cables available |

| MEMS Sensor | ±156.96 m/s2 ( ±16 g) – 1,000 Hz |

| Piezo Sensor | ±490.50m/s2 ( ±50g) – 10kHz |

| Operating temperature | -40℃ to 85℃ |

| Impact resistance | 98,100 m/s2 ( 10,000 g) |

| Communication protocol | Modbus TCP / Modbus RTU on RS485 |

Related Products

-

TSUBOSAN Diamond Files K-Type #150 Diamond Files

-

Japan Clamp BEC Beam Lifting Clamp (With Remote Control)

-

Matsuda Seiki SF200 type Superfinish Polishing Machine

-

Chiyoda Seiki Pressure Switch Device Pressure Gauge/Pressure Switch Equipment Pressure Gauge With Contact

-

LOBTEX SD5S Swaging Die Set

-

Shimizu Rammer for Electric Hammer – Tip Tool