H&F, Japan

H&F Transfer Press Line

Made in Japan

Manufacturer: Hitachi Zosen Fukui Corporation.

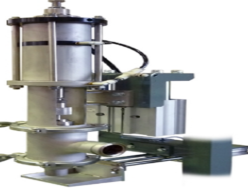

Product name: Transfer Press Line

We can offer you transfer press line compatible with a wide range of forming applications, including aluminum sheets.

We developed and commercialized the world’s first three-dimensional transfer press in 1973. Since then, we have delivered it to domestic and other countries around the world.

You can select a veriety of the slide drive methods such as link drive, crankless drive and servo drive incorporating the latest servo technology.

We design and manufacture distack feeder which can stably transfer steel and aluminum sheets. Transfer device for transfer press controlled by servo motor has a capacitor bank and can safely stop operations without any interference and in synchronization with the position of the slide even in the event that an unexpected power outage occurs.

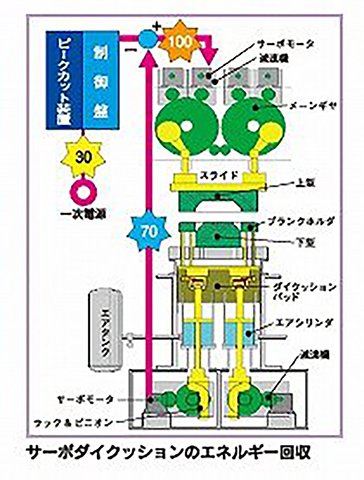

In addition, we can propose you transfer press equipped servo cushions which improve panel formability and contribute to energy saving.