Just Co., Ltd.

Just Corporation JPN PTC Air Duct Heater

Product Made in Japan

Manufacturer: Just Corporation

Model: JPN PTC

Product Summary

PTC duct heaters use a PTC heater (semiconductor ceramic heater) as the heat source and are duct heaters for heating air in temperatures up to 100°C.

By adopting this PTC heater, the duct heater’s shape has been made about 1/4 of the size of conventional products. Furthermore, due to the excellent properties of the PTC heater, it has the following functions.

■Features

Compact

Each PTC heater element has a compact size of 90 x 130 x 26t, and the shape of the duct body is 1/4 the size of conventional models.

Safety

①The self-temperature control function prevents the heater surface temperature from rising above 230°C.

②The heater surface temperature remains constant at a maximum of 230°C, so there is no need to worry about burning out even in windless conditions.

Energy saving

①The self-temperature control function is a safety feature that allows the heater itself to control the amount of heat generated in response to increases or decreases in airflow.

② Energy saving is achieved through self-temperature control that reduces the wattage according to the maximum heater surface temperature.

Quick response

①It has a rapid heating function that reaches the maximum heater surface temperature (230°C) in 5 seconds.

②It will heat up after 5 seconds and cool down after 20 seconds after switching it off.

Inexpensive

The compact design has made it possible to reduce costs compared to conventional products.

Options

It is possible to install a blower and control panel.

*Our PTC heater (Z type) is equipped with AL fins to enhance the heat dissipation effect, resulting in a highly efficient structure.

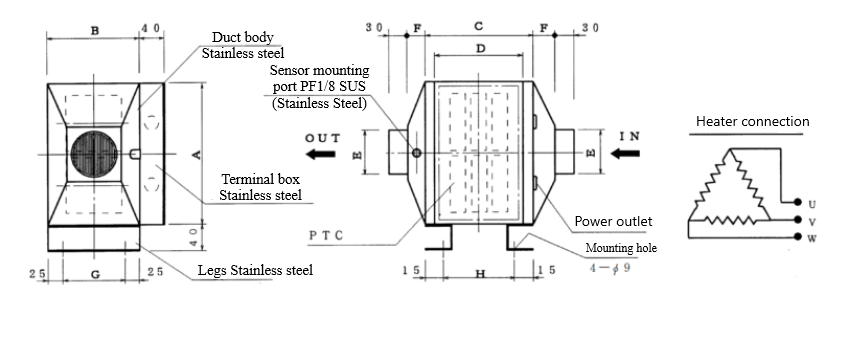

Appearance and Dimensions

Format Table

| JPN-1 | JPN-2 | JPN-3 | ||||||||

| 3.0 | 3.6 | 4.5 | 6.0 | 72 | 9.0 | 9.0 | 10.8 | 13.5 | ||

| 1.7 | 2.0 | 2.5 | 3.3 | 4.0 | 5.0 | 5.0 | 60 | 7.5 | ||

| Discharge maximum temperature (°C) | 100°C (Please use with inlet air temperature and humidity at or above 0°C and 85% RH or higher.) | |||||||||

| Heater element arrangement | rows | 1 | 2 | 3 | ||||||

| stages | 3 | 3 | 3 | |||||||

| 3 | 6 | 9 | ||||||||

| A | 130 | 230 | 330 | |||||||

| B | 150 | 150 | 150 | |||||||

| C | 180 | 280 | 280 | |||||||

| D | — | 180 | 180 | |||||||

| E | 075 | 俗100 | 0100 | |||||||

| F | 035 | 35 | 35 | |||||||

| G | 100 | 100 | 100 | |||||||

| H | 205 | 250 | 250 | |||||||

| Weight (kg) | 約3.0 | >94.2 | 約7.2 | |||||||

| Remarks: |

| |||||||||