H&F

H&F Piler

Manufacturer: H&F Corporation

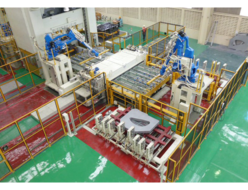

High-Performance Pilers for Automotive Panels

We specialize in manufacturing large 2-tier pilers for automotive outer panels, as well as medium and small-sized pilers for inner panels. Our pilers ensure stable and efficient piling, regardless of the type or shape of the sheets being processed.

For outer panels, our pilers feature a multi-row solenoid magnet conveyor and use a soft piling method, which decelerates the conveyor during piling to ensure precise sheet alignment. For inner panels, we offer pilers designed for multi-column loading of small and deformed sheets, as well as orderly stacking of processed sheets on pallets.

We also produce versatile pilers capable of stably piling both iron and aluminum sheets, offering flexibility and efficiency across a range of material types.

Features:

Stop Piling Method

Our pilers use a stop piling method, stopping the conveyor when sheets fall to prevent collisions. This reduces friction between sheets and minimizes damage, ensuring high-quality piling throughout the process.

Soft Piling Method

With the soft piling method, our pilers decelerate the conveyor before the sheets fall, reducing friction and impact with the stopper. This method improves sheet alignment and reduces the risk of flaws during piling.

Multi-Row Conveyor with Adjustable Width

The multi-row conveyor in our pilers features an adjustable width to prevent sheet deflection. By minimizing friction between sheet edges and the belt, our pilers can operate at high speeds while maintaining top performance. For aluminum sheets, we also offer a vacuum conveyor option.

Examples:

Piler for Wide Outer Sheets

This piler uses a multi-row solenoid magnet conveyor to alternate sheet piling between lanes at high speed. The soft piling method ensures friction is minimized, delivering perfect alignment for wide outer sheets.

Dropping Piler for Inner Sheets

Our dropping piler stably handles inner sheets at high speed. The auto fork system reduces press line stoppage during stack changes, improving overall productivity.