SAKURA SEISAKUSHO LTD.

Sakura Seisakusho Static Mixer

Made in Japan

Manufacturer: SAKURA SEISAKUSHO LTD.

Dramatically improves the process of mixing, melting, reaction and heat exchange.

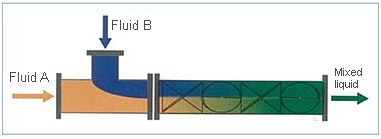

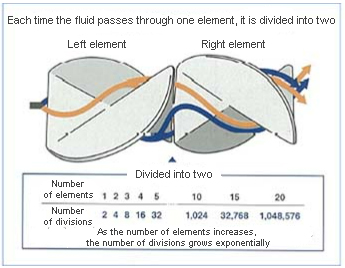

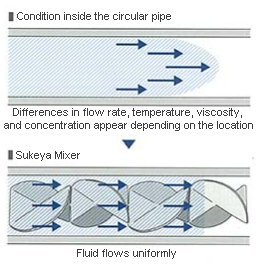

The Square Mixer uses a specially constructed plate called an element inside a pipe that efficiently disperses, dissolves, emulsifies, reacts, and exchanges heat by continuously “dividing,” “reacting,” and “mixing” the fluid. Since it has a simple structure and no drive unit, it is an epoch-making product that can mix while moving the inside of the Square Mixer from tank to tank and from device to device. The Square Mixer can be used for liquids, gases, slurries and other fluids and is an economical and compact device.

Functions and Features

・Since the fluid rotates, there is no drive unit and has a simple structure that does not require a power supply.

・It has simple structure that enables easy cleaning of the inside.

・The inside of the mixer is turbulent and mixes various fluids efficiently

・High cost performance with almost no consumable parts.

Principle of mixing

Homogenization

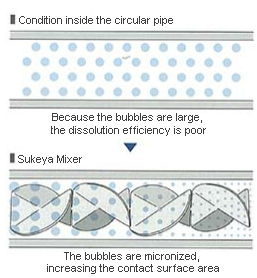

Gas absorption

Field of application

Square Mixers can handle a wide variety of fluids and are used and applied in many industries.

Water Treatment

・pH adjustment

・Aeration (oxygen saturation) and microbubble production

・Addition of chemicals to water

・Mixing of coagulators to water

・Ozone water production

・Disinfection of water supply by sodium hypochlorite

Chemistry

・Absorption, reaction and mixing of source gas

・Mixing and reaction of liquid materials

・Production of aqueous ammonia

・Polymerization of resins

・Homogenization

・Mixing of additives, etc.

・Heating and cooling of viscous materials

Paper / Pulp

・Dilution of chemical solution

・Gelatinization of starch, direct heating

・Warm water and hot water production

・Pulp bleaching by chlorine gas

・Production of calcium hypochlorite and its reaction with chlorine

Food

・Mixing of raw materials

・Direct heating. cooking by joint heating, heat sterilization, cooling

・Warm water and Hot water production (CIP)

・Absorption of carbon dioxide, etc.

Pharmaceuticals and Cosmetics

・Dilution and mixing of crude materials and stock solutions

・Mixing of raw materials

・Warm water and Hot water production (CIP)

・Heat inactivation of recovered enzymes

・Heating and cooling of paste, gel ingredients and products

Electronics and Semiconductor

・Mixing and viscosity adjustment of raw materials

・Dilution and mixing of raw materials and stock solutions

・Dilution of Washing Water (Hydrofluoric acid)

・Mixing of gases

・Prevention of precipitation of slurry raw materials, etc.