OKANO VALVE MFG. CO.

Okano Valve Steel Castings

Made in Japan

Manufacturer: OKANO VALVE MFG. CO.

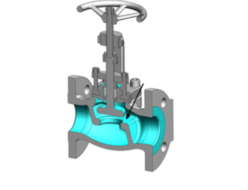

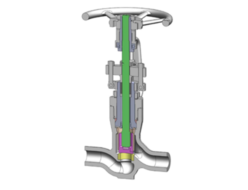

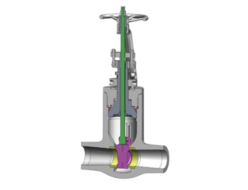

OKANO VALVE manufactures high pressure and high temperature valves for nuclear power plants and thermal power plants.

From 1943,OKANO VALVE has been developing and manufacturing cast steel materials, based on OKANO VALVE’s philosophy that “superior valves are made by superior materials”.

With the knowledge accumulated over several decades,OKANO VALVE has been acclaimed by our clients for using state of the art casting techniques and superior cast steel materials. So we provide not only valves,but also various types of steel casting.

Scope of Steelmaking

| Material | JIS standards | ASTM standards |

|---|---|---|

| JIS G 5151 SCPH2 JIS G 5151 SCPH21 JIS G 5151 SCPH32 JIS G 5151 SCPH61 JIS G 5152 SCPL1 | ASTM A216 WCB、 WCC ASTM A217 WC6 ASTM A217 WC9 ASTM A217 C5 ASTM A352 LCB ASTM A217 C12A | |

| Other | ||

| Fire SCPH91 (ignition standard) | ||

| SCWB36 *Proprietary material developed by Okano DIN standard material: material standard WB36 (Material equivalent to 15NiCuMoNb5 pipe material) | ||

| Weight | Maximum product weight: approx. 6 t, measurement : 2000mm x 1800mm x 1000mm | |

Features

1.Products of superior quality / Rapid Product Delivery

Our industry leading products have undergone stringent safety and quality examinations to receive the requisite certification compulsory for Ultra Supercritical and Nuclear Power Plants.

Okano Valve’s manufacturing process is quite unique, being that we have the capability to design and manufacture products with the specifications requested personally by our clients. This in-turn reduces the lead time between the placement of an order and delivery of finished products.

2.Material Development

At our fully equipped engineering lab, we conduct various tests and research in an effort to develop new materials. At this lab, we conducted research on the development of 9Cr-1Mo steel, and in 1986, we perfected a technology that became the world’s first. In 1996, we filed another application on a new material to the committee that revises technical standards for power generation. As a result, the current ignition standard “Fire SCPH91” was established.

3.Various achievement

Our extensive experience as an industry leader provides confidence for our clients that Okano Valve’s products are the safety and of the highest quality.

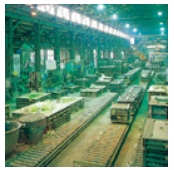

Main Facilities

| 8t AC arc furnace | maximum molten weight 11.5t | 1 unit |

|---|---|---|

| 2t High-frequency induction furnace | maximum molten weight 2.5t | 1 unit |

| Immersion pyrometer | Max.1750°C | 1 unit |

| Heat treatment facilities | kerosene type capacity 15t | 1 unit |

| electric type capacity 7t | 1 unit | |

| electric type capacity 3t | 1 unit | |

| Molding equipments | self-hardening sand molding equipment | 1 unit |

| greensand molding equipment (jolt type) | 1 unit | |

| coremaking equipments (Co2 type,self-hardening type) | 1 unit each | |

| Shake-out machines | 15t,1t | 1 unit each |

| Automatic sand processing equipment | 5t / Hr | 1 unit |

| Sand slinger | 0.25m3/Min. | 1 unit |

| Air blasting machine | Max.1t | 1 unit |

| Shot blasting machines | monorail type,turn blast type | 1 unit each |

| Continuous | 15t / h, 5t / h | 1 unit each |

| Batch sand mixers | 400kg,50kg | 2 unit each |