NIPPON FURNACE KOGYO KAISHA LTD.

Nippon Furnace Instrumentation For Control Of Boiler Operation

Made In Japan

Manufacturer: NIPPON FURNACE KOGYO KAISHA LTD.

Burners & Combustion Equipment Business

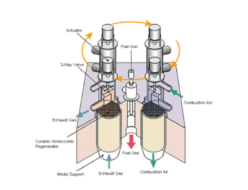

Nippon Furnace began manufacturing combustion burners after World War II through technical licensing agreements with well-known companies like Bloom, Coen, Pillard, and Forney. Later, it introduced high-efficiency burners developed in its own R&D facilities, securing a strong position in the combustion market. In 1987, the company intensified R&D efforts to develop the High Cycle Regenerative Combustion System (HRS) to address global environmental concerns and economic growth. Adopted in Japan’s High Performance Furnace Development Project, HRS burners have, since 1999, demonstrated a 30% reduction in fuel consumption and NOx emissions. NFK’s burners are now acclaimed worldwide for their efficiency and quality.

Burners & Combustion Equipment

industrial Furnaces equipped with Regenerative Burners(HRS Burners)

- HRS-DL Type Heat Treatment & Annealing Furnaces

- HRS-RT Type Heat Treatment Furnaces

- HRS-RT Type Aluminum Heat Treatment Furnaces

Burner for Fired Heater • Burner for Rotary Kiln

- Air Staged Low NOx Burner for Fired Heater of Refinery

- Fuel Staged Low NOx Burner for Fired Heater of Refinery

- Three (3) Fuel Burner for Rotary Kiln

Burners for Boiler • Economizer

- NNFK-LND Type Oil Fired Low NOx Burner

- NFK-LPCF Type Large Gas Fired Burner for Low Calorie Fuel

- NFK-ULN Type Gas Fired Low NOx Burner

- NFK-CGT Type Regenerator for Gas Turbine Exhaust

- NFK-ECG Type Anti-Corrosion Glass Economizer

Energy Saving Equipment & Maintenance for Boiler

- Heat Recovery & Energy Saving Equipment for Boiler

- Automatic Operation Control System & Remote Control System for Boiler

- Test Operation, Periodical Inspection & Maintenance Service of Boiler

Other Combustion & Energy Saving Equipment

- NFK-DEKA Air Pre-Heater

- A.I./S.I.(Air/Steam Enthalpy Intensifier)

- High Temperature/Pressure Indirect Hot Air Generator

- High Pressure/Enthalpy Intensified Combustor

- FCC/RFCC Air Heater

- Fired Heater

- Flame Detector

- COG Filter

Regenerative Burners (HRS Burners)

- HRS-DL Burner (Direct Firing Type)

- HRS-DF Burner (Direct Firing and Non-Oxidizing/Reducing Type)

- HRS-RT Burner (Radiant Tube Type)

- HRS-U1 Burner (Package Type Direct Firing Type)

- HRS-UX Burner (Continuous Fueling Direct Firing Type)

- HRS-CEM (Four Way Valve)

Energy Saving Equipment and Maintenance Service for Boil

Instrumentation for Control of Boiler Operation

- For combustion control in the boiler, both the latest digital control technology and the conventional analog control technology are available.

- The burner management system has built-in safety features such as state-of-the-art technology for control of O2 supply and NOx emissions and measures to deal with instantaneous blackouts.

- The unit has been designed for remote operation using a TV monitor and data transmission.

INV-F Type Inverter Control System

- Can be adapted to turndown ratio of 10:1

- Superior controllability and safety

- Capable of additional O2 trimming and inverter of splashing combustion pump. Applicable electric motor capacity: 0.4kw to 150kw

Test Operation and After Service

- NFK’s team of well-trained and experienced engineers are available for dispatch worldwide for test operations and adjustment of systems.

- The company also offers other technical support such as periodic checking and adjustment of equipment and systems, and periodic servicing of equipment under maintenance agreements with respective client.

- Technical consultation on thermal systems.