Miyawaki

Miyawaki DC1 Diaphragm Steam Traps

Manufacturer: MIYAWAKI Inc.

Model: DC1

Features

Compact design

Can be installed in small spaces.

Stainless steel

Highly resistant to corrosion.

No steam leaks

Operates below saturation temperature, resulting in no steam leaks and great energy saving performance. Available are two different capsule designs. H: discharges hot condensate at approximately 5℃ (9℉) below saturation temperature. L: discharges hot condensate at approximately 15℃ (27℉) below saturation temperature.

Easy maintenance

Less components make maintenance and inspection easy.

Typical applications

Suitable for F&B devices, bio devices, compact heat exchangers, tank heating, main heat pipes, steam tracing, cleaning devices, and similar applications.

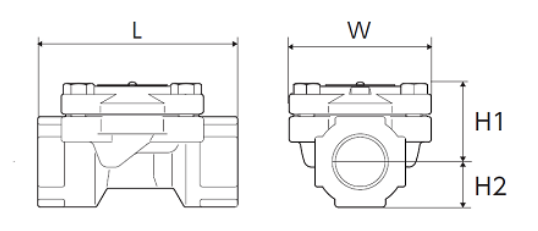

Dimensions/Weight

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/4” | 65 | 29 | 11 | 53 | 2.6 | 1.4 | 0.4 | 2.1 | 0,4 | 0.9 |

| 3/8” | ||||||||||

| 1/2” | 75 | 31 | 17 | 3.0 | 1.2 | 0.7 | 0,5 | 1.1 | ||

| 3/4” | ||||||||||

| 1” | 80 | 34 | 21 | 3.1 | 1.3 | 0.8 | ||||

Specifications

| Model | Connection | Max. operating pressure | Max. operating pressure differential | Max. operating temperature | Valve opening temperature | Body material | |||||

| Type | Size | (MPa) | (psig) | (MPa) | (psig) | (℃) | (℉) | (℃) | (℉) | ||

| DC1-21H | Screwed Rc,NPT | 1/4” | 2,1 | 305 | 2,1 | 305 | 220 | 428 | 5℃ below saturation temperature | 9℉ below saturation temperature | Stainless cast steel SCS13A/CF8 |

| 3/8” | |||||||||||

| 1/2” | |||||||||||

| 3/4” | |||||||||||

| 1” | |||||||||||

| DC1-21L | 1/4” | 15℃ below saturation temperature | 27℉ below saturation temperature | ||||||||

| 3/8” | |||||||||||

| 1/2” | |||||||||||

| 3/4” | |||||||||||

| 1” | |||||||||||

*Screwed flange is available. Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

Maximum allowable pressure (PMA): 2,1 MPa (305psig) PMA is the pressure that can be tolerated by pressure-resistant parts (body).

Maximum allowable temperature (TMA): 220℃ (428℉) TMA is the temperature that can be tolerated by pressure-resistant parts (body).

Minimum operating differential pressure (⊿PMN): 0,01MPa (1.5psig) ⊿PMN is the minimum operating differential pressure between the trap inlet and outlet.

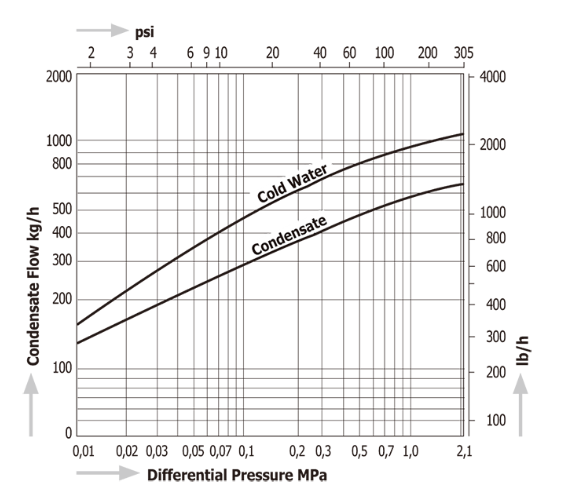

Discharge Capacity