Nippon Avionics Co., Ltd.

Avio NRW-IN4200 Resistance Welder Inverter

Manufacturer: Nippon Avionics Co., Ltd.

Model: NRW-IN4200

Features of NRW-IN4200

- Multi Control Mode: constant current, voltage or power

- Pre-Weld Check

- Long Weld Time: maximum 3 sec

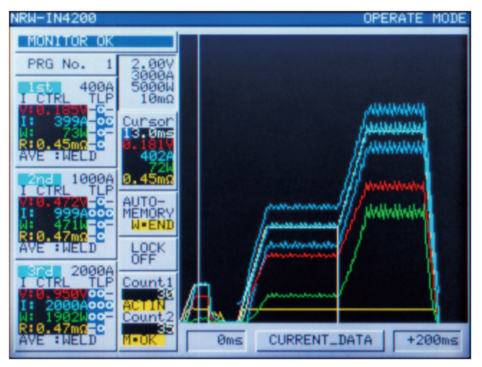

- Graphic Waveform Display: large LCD display of welding waveform

- Multi Parameter Monitoring

- Welding Waveform Memory

Graphic Display of Welding Waveform

Resistance Welding Power Supplies Specifications of NRW-IN4200

| Item | NRW-IN4200 |

|---|---|

| Control Frequency | 2kHz |

| Control Mode | Secondery current effective value control, Secondery voltage effective value control, Secondary power effective value control, Fixed pulse width control |

| Range of Output Setting | Current: 400 – 4100A Voltage: 0.400 – 4.100V Power: 200 – 8200W Pulse width:0.0 – 90.0% |

| Range of Timer Setting(ms) | 0.0-3000.0(Total time of UP TIME、WELD TIME、DOWN TIME、COOL TIME) |

| Limit Monitoring Function | Avarage value/peak value monitoring of current, voltage, power, resistance respectively |

| Other Monitoring Functions | Profile monitor, Trace monitor |

| Waveform Image Memory | Avairable to save 8 images(Including the last welding result) |

| Number of Conditions | 31 |

| Interface | RS-232C、I/O、Analog output |

| Cooling Method | Air |

| Power Source | 3φ AC200-230V ±10% 50/60Hz |

| Dimensions(mm) | W170 × D350 × H265 (Excluding protrusions) |

| Weight | ≒15kg |

| Welding transformer | NT-IN4448、NT-IN4474、NT-IN4436 |

Resistance Welding Transformer Specifications

| Model | NT-IN4474 | NT-IN4436 | NT-IN4448 |

|---|---|---|---|

| Power Supply Voltage | 220V | ||

| Cooling Method | Air | Air | Dual Use of Air or Water |

| Frequency | 2kHz | ||

| Rated Capacity | 11kVA | 8.8kVA | 23kVA |

| Transformer Turns Ratio | 37:1 | 18:1 | 24:1 |

| No Load Secondary Voltage | 8.4V | 17.2V | 12.9V |

| Maximum Output Current | 4000A | ||

| Maximum Duty Cycle | 5% | 5% | 5%(Air)、10%(Water) |

| External Dimensions (mm) (Excluding Protrusions) | W150×D337×H222 | W150×D267×H250 | W170×D312×H235 |

| Weight | ≒14kg | ≒14kg | ≒19kg |

Related Products

-

Avio PWB Printed Wiring Board Repairing Equipment

-

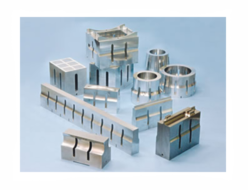

Avio Ultrasonic Hon & Anvil

-

Avio NA Series Welding System Head for Resistance Welder

-

Avio NA-54LA Hand Piece Type Head For Resistance Welder

-

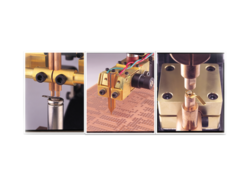

Avio EH/EP/EO/EL Series Welding Electrode And Resistance Weldability

-

Avio Standard Model Small Size Ultrasonic Metal Welder