Nippon Avionics Co., Ltd.

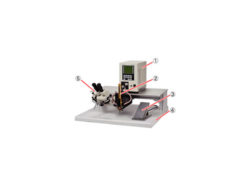

Avio PHU-35 Pulse Heat (Hot Bar) Soldering Machine High Power Type

Manufacturer: Nippon Avionics Co., Ltd.

Model: PHU-35

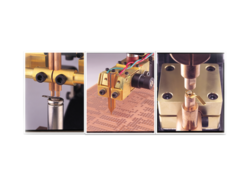

High Power Type Pulse Heat (Hot Bar Soldering Machine) PHU-35 is suitable for heat caulking of plastic cases, wide size ACF and soldering.

High Power Type with separate power supply and transformer, suitable for mounting on automatic machines.

Feature of PHU-35

- High Reliability Joining

Apply pressure while controlling heating and cooling to prevent workpiece shifts during the joining process.Variable Temperature Profile

Minimize thermal impact on peripheral components with localized and instantaneous heating.High Reproducibility

Ensure consistent temperature and time control using digital PID, eliminating the need for operator expertise.Pb-Free Compatibility

Easily handle Pb-free solder with higher temperature settings and longer heating times.User-Friendly Interface

Connect seamlessly to external equipment and automated systems via the standard RS-232C&I/O interface.Advanced Monitoring Functions

Monitor temperature (average and peak values) and detect anomalies such as excessive temperature rise or thermocouple disconnection.Additional Features

- Memory for 15 setting conditions

- Electric valve control for the heater tip and tool

- Auxiliary thermocouple monitoring

Pulse Heat (Hot Bar) Soldering Power Supply Specifications

| Item | PHU-35/NT-35 |

|---|---|

| Heating temperature | Room temperature – 600℃ 1℃ step E type/J type Room temperature – 900℃ K type (option) |

| Heating time | 000-999 ( x 100ms, x 10ms) |

| Rated capacity | 3KVA (50%) |

| Heat control | 2 steps |

| Monitor function | Temperature |

| Interface | RS-232C, I/O |

| Transformer | NT-35 |

| Transformer secondary voltage | 1.0V, 2.0V, 3.0V |

| Power Source | Single phase AC200V – 230V±10% 30A (Option: AC100 – 115V)* |

| Dimensions | PHU-35: W278 × D250 × H120mm NT-35: W200 × D270 × H220mm |

| weight | PHU-35: ≒ 7.4kg NT-35: ≒ 25kg |

Related Products

-

Avio NA-54LA Hand Piece Type Head For Resistance Welder

-

Avio QC-450 Resistance Welding Monitor

-

Avio NRW-IN900P Resistance Welder High-Reliability Inverter

-

Avio PWB Printed Wiring Board Repairing Equipment

-

Avio FG-500 Digital Force Indicator

-

Avio EH/EP/EO/EL Series Welding Electrode And Resistance Weldability