Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NAS74N Corrosion Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NAS74N

NAS74N (UNS S32750)

High Corrosion Resistant Super Duplex Stainless Steel

NAS74N is a super duplex stainless steel with a pitting resistance equivalent (PRE*) number higher than 40, which provides not only excellent corrosion resistance but also excellent strength properties. In particular, NAS74N has superior localized corrosion resistance compared with UNS S32205 (NAS329J3L, SUS329J3L), and UNS S32506 (NAS64, SUS329J4L). Therefore, industries utilize NAS74N for applications in severe environments, including chemical plants and desalination facilities, due to its superior corrosion resistance and mechanical properties Nippon Yakin supplies NAS74N in the form of plate, sheet, and strip.

*PRE = %Cr + 3.3 × %Mo + 16 × %N

| Chemical Composition | 25Cr, 7Ni, 3.8Mo, 0.27N | ||

| Product Shape |

|  Sheet Sheet |

|

| Workability | Attention should be paid to the strength behavior of NASTM which increases below 1000°C despite lower strength than Type 304 at high temperatures. Solution annealing is necessary after hot working. | ||

| Weldability | Conventional welding processes including GTAW (TIG), GMAW (MIG) can be used. Use filler metals for UNS S32750. It is advisable to avoid preheating when working with NAS74N, as it may lead to undesirable effects on the material’s properties. | ||

| Heat Treatment | Solution annealing of NASTM should be performed between 1025°C to 1125°C, followed by quick quenching to prevent brittleness. | ||

| Pickling | We apply a mixture of nitric and fluoric acids for pickling to effectively remove surface contaminants and enhance the material’s corrosion resistanceImmersion in fused salt before pickling is effective. | ||

| Applications | Seawater desalination plant, Environment-related equipment, Chemical plants, Seawater pump. | ||

| Certification | Can be manufactured to UNS S32750 in accordance with the NORSOK standard. Thickness up to 40mm. | ||

Steel Grade/Standard

| Nippon Yakin Grade | JIS G 4304/4305 | ASTM A240 | EN 10088-2/10028-7 |

| NAS 74N | SUS 327L1 | UNS S32750 | 1.4410 |

Chemical Composition

| Specification | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | [wt %] |

| Specification (SUS 327L1) | ≤0.030 | ≤0.80 | ≤1.20 | ≤0.035 | ≤0.020 | 6.00~8.00 | 24.00~26.00 | 3.00~5.00 | ≤0.50 | 0.24~0.32 | — |

| Specification (UNS S32750) | ≤0.030 | ≤0.80 | ≤1.20 | ≤0.035 | ≤0.020 | 6.00~8.00 | 24.00~26.00 | 3.00~5.00 | ≤0.50 | 0.24~0.32 | ≥41 |

| Specification (EN 1.4410) | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.015 | 6.00~8.00 | 26.00~26.00 | 4.5 | — | — | |

Physical Properties

| Density | g/cm³ | 7.8 |

| Specific heat | J/kg·K | 453 |

| Electrical resistivity | µΩ·cm | 83 |

| Thermal conductivity | W/m·K | 12.3 |

| Average coefficient of thermal expansion 10⁻⁶/°C | 30~100°C | 13.4 |

| 30~200°C | 13.7 | |

| 30~300°C | 13.8 | |

| 30~400°C | 14 | |

| Young’s modulus | MPa | 19.7 × 10⁴ |

| Magnetism | Y (magnetizable) | |

| Melting range | °C | 1390~1455 |

Mechanical Properties at Room Temperature

| Specification | 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HBW] | Impact Value R.T./V-notch/Fullsiz [J] |

|---|---|---|---|---|---|

| Specification (SUS327L1) | ≥550 | ≥795 | ≥15 | ≥310 | — |

| Specification (UNS S32750) | ≥550 | ≥795 | ≥15 | ≥310 | — |

| Specification (EN 1.4410) | ≥530 | 730~930 | ≥20 | ≥100 (long) | — |

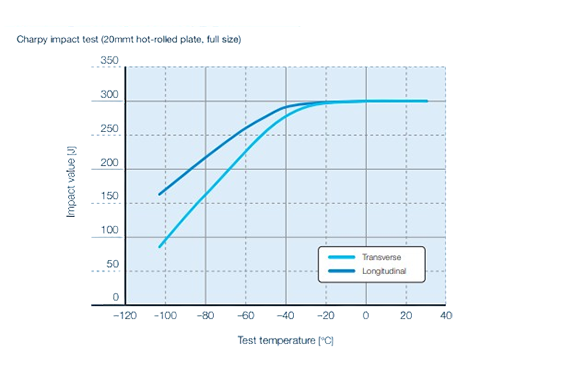

| Hot-rolled plate 20mm | 588 | 849 | 38 | 235 | 298 |

| Hot-rolled plate 8mm | 655 | 880 | 37 | 255 | 298 |

**EN 10088-2 hot rolled plate

Impact Value

Corrosion Resistance

NAS74N has excellent localized corrosion resistance (pitting corrosion, crevice corrosion) and acid resistance in comparison with Type 304, Type 316L, NAS329J3L (UNS S32205), NAS64 (UNS S32506).

Pitting Corrosion Resistance

| Alloy | ASTM G48 Method A | ASTM G48 Method C |

| 22°C | 50°C | |

| NAS329J3L | O | X |

| NAS64 | O | O |

| NAS74N | O | O |

Test conditions: ASTM G48 Method A (O: No pitting corrosion, ×: Pitting corrosion)

Test solution: 6%FeCl3

Test temperature: 22°C, 50°C (Recommended temperature in this test)

Test time: 72h

Crevice Corrosion Resistance

| Alloy | ASTM G48 Method D |

|---|---|

| NAS329J3L | 25 |

| NAS64 | 30 |

| NAS74N | 45 |

Test conditions: ASTM G48 Method D

Test solution: 6%FeCl3 + 1%HCl

Test time: 72h

Acid Resistance

| Alloy | 5% | 10% | 20% | 40% | 60% | 80% |

|---|---|---|---|---|---|---|

| NAS329J3L | 0.01 | 0.17 | 4.65 | 365.9 | 1456 | 106.4 |

| NAS64 | < 0.01 | 0.02 | 1.07 | 191.9 | 1054 | 60.72 |

| NAS74N | 0.02 | 0.02 | 1.30 | 79.91 | 548.6 | 99.53 |

Test time: 24h

Corrosion rate in sulfuric acid at 80°C (mm/y)

| Alloy | 5% | 10% | 20% | 40% | 60% | 80% |

|---|---|---|---|---|---|---|

| NAS329J3L | 0.01 | 0.17 | 4.65 | 365.9 | 1456 | 106.4 |

| NAS64 | < 0.01 | 0.02 | 1.07 | 191.9 | 1054 | 60.72 |

| NAS74N | 0.02 | 0.02 | 1.30 | 79.91 | 548.6 | 99.53 |

Test time: 24h

Corrosion rate in hydrochloric acid at 80°C (mm/y)

| Alloy | 0.1% | 1% | 2% | 3% |

|---|---|---|---|---|

| NAS329J3L | 0.02 | 0.03 | 31.10 | 60.62 |

| NAS64 | 0.01 | 0.01 | 12.94 | 30.51 |

| NAS74N | 0.01 | 0.01 | 0.01 | 44.75 |

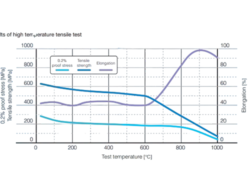

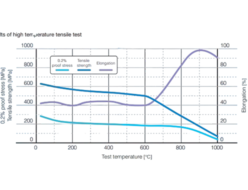

Workability

Manufacturers must pay attention to the strength behavior of NAS74N, which experiences a significant increase below 1000°C despite having lower strength than Type 304 at high temperatures. After hot working, they should carry out solution annealing. Additionally, they must consider the cold workability of NAS74N due to its higher proof stress and lower elongation compared to Type 304

Weldability

Conventional welding processes including GTAW (TIG), GMAW (MIG/MA) can be used. We recommend using filler metals for UNS S32750 to ensure optimal welding performance and structural integrity. Neither preheating nor post-weld heat treatment is necessary. Interpass temperature should be no more than 100°C in order to prevent precipitation of intermetallic compounds of σ phases that result in brittleness.

Heat Treatment

Perform solution annealing of NAS74N within the temperature range of 1025°C to 1125°C. After this process, quickly dip the material into water or use other approved methods according to ASTM A480/A480M. This practice helps prevent brittleness at 475°C and inhibits the formation of σ phases.

Pickling

We apply a mixture of nitric and fluoric acids for pickling to effectively remove surface impurities and enhance corrosion resistance. In addition, due to its higher corrosion resistance, immersion into fused salt bath before pickling is significantly effective to take scale off. And further occasion shot blasting before pickling is extremely effective.

Applications

Seawater desalination plant, Environment-related equipment, Chemical plants, Seawater pump.

Certification

It is possible to manufacture UNS S32750 in accordance with the NORSOK standard below. The thickness is up to 40mm.

- NORSOK M-650

- NORSOK M-630 MDS D55

Related Products

-

Nippon Yakin Kogyo NASNW276 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS8R10 Neutron Absorbing Stainless Steel

-

Nippon Yakin Kogyo NAS825 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASNi201 Corrosion Resistant Pure Nickel

-

Nippon Yakin Kogyo NASH880 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASNW400 Corrosion Resistant Alloys

Coil

Coil Plate

Plate