Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASNW276 Corrosion Resistant Alloys

In this alloy, reducing the contents of C and Si suppresses carbide precipitation in the heat-affected zone (HAZ) and improves corrosion resistance. Based on these features, industries widely use NASNW276 in materials subjected to severe environments, such as chemical plants.

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NASNW276

NASNW276 (UNS N10276)

High Corrosion Resistant Nickel Alloy

NASNW276 is a Ni-Cr-Mo alloy with excellent corrosion resistance in both oxidizing and reducing atmospheres.In this alloy, reducing the contents of C and Si suppresses carbide precipitation in the heat-affected zone (HAZ) and improves corrosion resistance. Based on these features, industries widely use NASNW276 in materials subjected to severe environments, such as chemical plants. Nippon Yakin supplies this product in plate, sheet, and strip forms.

In this alloy, reducing the contents of C and Si suppresses carbide precipitation in the heat-affected zone (HAZ) and improves corrosion resistance. Based on these features, industries widely use NASNW276 in materials subjected to severe environments, such as chemical plants.

| Chemical Composition | 59Ni 15Cr 16Mo 4W 5Fe | ||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Workability | High-temperature strength is higher than Type 304. Cold workability is similar to standard austenitic stainless steels like Type 304, 316, etc. You must consider the high strength of the material in cold working. | ||

| Weldability | Ordinary welding methods can be used. Matching welding consumables should be used. You do not need to perform post-weld heat treatment. | ||

| Heat Treatment | Solution annealing at 1150–1170°C, followed by quenching in water or rapid cooling. | ||

| Pickling | Nitric acid and hydrofluoric acid used in pickling. You will find descaling more difficult compared to Type 304.. Alkaline immersion before pickling and shot blasting are effective. | ||

| Applications | Chemical plants, Flue gas desulfurization plants, Oil and gas extraction, Heat exchangers. | ||

| Chemical Composition | 59Ni 15Cr 16Mo 4W 5Fe | ||

Grade/Standard

| Nippon Yakin Grade | JIS G 4902 | ASTM B575 | DIN 17744/17750 |

|---|---|---|---|

| NASNW276 | NW0276 | UNS N10276 | 2.4819 |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Mo | Fe | Co | W | V | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification (NW0276) | ≤0.010 | ≤0.08 | ≤1.00 | ≤0.040 | ≤0.030 | Bal. | 14.50-16.50 | 15.00-17.00 | 4.00-7.00 | ≤2.50 | 3.00-4.50 | ≤0.35 |

| Specification (UNS N10276) | ≤0.010 | ≤0.08 | ≤1.0 | ≤0.04 | ≤0.03 | Bal. | 14.5-16.5 | 15.0-17.0 | 4.0-7.0 | ≤2.5 | 3.0-4.5 | ≤0.35 |

Physical Properties

| Density [g/cm³] | 8.90 |

|---|---|

| Specific heat [J/kg•K] | 400 |

| Electrical resistivity [μΩ•cm] | 130.0 |

| Thermal conductivity [W/m•K] | 9.9 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 20–100°C 12.1 |

| 20–200°C 12.7 | |

| 20–300°C 13.0 | |

| 20–400°C 13.3 | |

| 20–500°C 13.5 | |

| Young’s modulus [MPa] | 21.1 × 10⁴ |

| Magnetism | None |

| Melting range [°C] | 1325–1369 |

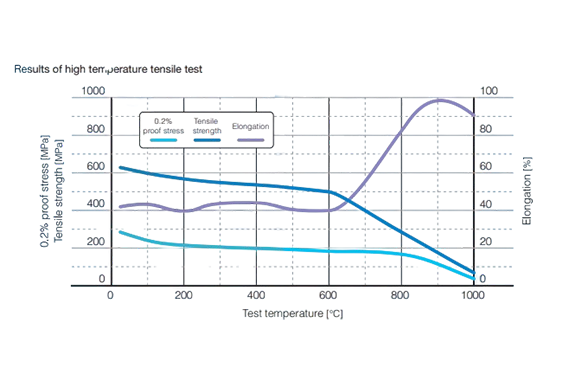

Mechanical Properties

| 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HRBW] | |

|---|---|---|---|---|

| Specification (NW0276) | ≥275 | ≥690 | ≥40 | — |

| Specification (UNS N10276) | ≥283 | ≥690 | ≥40 | — |

| Hot-rolled plate (14mm) | 372 | 763 | 71 | 83 |

| Cold-rolled sheet (2mm) | 366 | 785 | 61 | 86 |

Corrosion Resistance

Pitting Corrosion Resistance

| Alloy | ASTM G48 Method A | ASTM G48 Method C Critical pitting corrosion temperature CPT (°C) |

|---|---|---|

| NAS185N | ○ | 70 |

| NAS254N | ○ | 80 |

| NASNW276 | ○ | >103 |

- Test conditions: ASTM G48 Method A (○: No pitting corrosion, X: Pitting corrosion)

Test solution: 6% FeCl₃

Test temperature: 22°C, 50°C (Recommended temperature in this test)Test time: 72h

Crevice Corrosion Resistance

| Alloy | ASTM G48 Method D Critical crevice corrosion temperature CCT (°C) |

|---|---|

| NAS185N | 40 |

| NAS254N | 45 |

| NASNW276 | 103 |

Test conditions: ASTM G48 Method D

– Test solution: 6% FeCl₃ + 1% HCl

– Test time: 72h

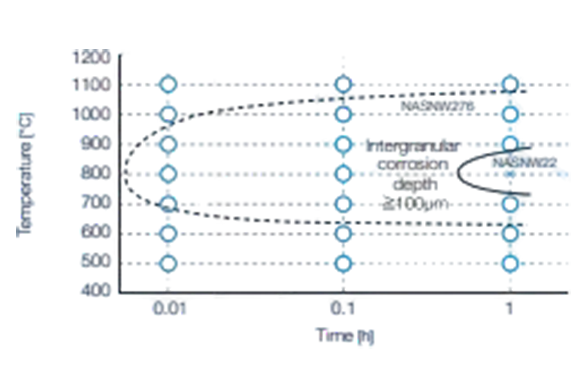

Intergranular Corrosion Resistance

Test conditions: ASTM G28 Method A

Test time: 24h

Boiling 50% H₂SO₄ – Fe (SO₄) solution

Stress Corrosion Cracking Resistance

| Alloy | MgCl₂ concentration (boiling point °C in brackets) | 45% (153°C) | 42% (149°C) | 40% (143°C) | 38% (136°C) | 35% (131°C) | 30% (123°C) | 25% (119°C) | 20% (110°C) |

|---|---|---|---|---|---|---|---|---|---|

| NAS185N | x | x | x | x | x | ○ | ○ | ○ | |

| NAS254N | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| NASNW276 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Test conditions:

– Immersion in boiling MgCl₂ solution

– Test time: 300h

– ○: No stress corrosion cracking, x: Stress corrosion cracking

– U-bend test specimen is used.

Acid Resistance

Corrosion rate in sulfuric acid at 80°C (mm/y)

| Alloy | 5% | 10% | 20% | 40% | 60% | 80% |

|---|---|---|---|---|---|---|

| NAS185N | 0.02 | 0.04 | 1.32 | 2.89 | 3.02 | 4.78 |

| NAS254N | 0.02 | 0.05 | 0.06 | 2.11 | 2.76 | 7.76 |

| NASNW276 | 0.01 | 0.02 | 0.03 | 0.05 | 0.08 | 0.34 |

Test time: 24h

Corrosion rate in hydrochloric acid at 80°C (mm/y)

| Alloy | 0.1% | 1% | 2% | 3% | 5% |

|---|---|---|---|---|---|

| NAS185N | 0.01 | 0.02 | 4.20 | 7.21 | — |

| NAS254N | 0.01 | 0.02 | 0.01 | 0.09 | 0.14 |

| NASNW276 | <0.01 | 0.03 | 0.04 | — | — |

Test time: 24h

Reference

| Alloy | JIS | UNS No. | Chemical Composition |

|---|---|---|---|

| NAS185N | SUS312L | S31254 | 20Cr-18Ni-6Mo-0.8Cu-0.2N |

| NAS254N | SUS836L | S32603 | 23Cr-25Ni-5.5Mo-0.2N |

| NASNW276 | NW0276 | N10276 | 56Ni-15Cr-16Mo-4W-5Fe |

Workability

Because the high-temperature strength of NASNW276 is extremely higher than that of Type 304, care is required when hot working. The cold workability of NASNW276 is basically the same as that of standard austenitic stainless steels such as Type 304, Type 316, etc. However, the fact that this is a high-strength material must be considered in cold working.

Weldability

In welding, it is possible to apply ordinary welding methods in the same manner as with stainless steels. Matching composition welding consumables should be used. Post-weld heat treatment is not required.

Heat Treatment

Solution annealing of NASNW276 is normally performed at the temperature range from 1150 to 1170°C followed by being quenched in water or rapidly cooled by

other means.

Pickling

A mixture of nitric acid and fluoric acid is used in pickling. However, because descaling is somewhat difficult in comparison with Type 304, alkali immersion before acid pickling, and if possible, shot blasting are extremely effective.

Applications

Chemical plants, Flue gas desulfurization plants, Oil and gas extraction, Heat exchangers.

Related Products

-

Nippon Yakin Kogyo NASNM17 Non-Magnetic Alloys

-

Nippon Yakin Kogyo NASNM15M Non-Magnetic Alloys

-

Nippon Yakin Kogyo NASNi201 Corrosion Resistant Pure Nickel

-

Nippon Yakin Kogyo NAS329J3L Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS325N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS64 Corrosion Resistant Alloys