Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASNW400 Corrosion Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NASNW400

NASNW400 (UNS N04400)

High Corrosion Resistant Ni-Cu Alloy

NASNW400 (NW4000, UNS N04400), with a composition comprising Ni and Cu, is an alloy which provides a combination of the noble metal properties of Cu and the passivation property of Ni and offers excellent corrosion resistance. Taking advantage of these properties, it is used in seawater desalination plants, heat exchangers, overlay materials for marine structures, and similar applications. Nippon Yakin supplies this product in plate, sheet, and strip form.

| Chemical Composition | 65Ni-32Cu-1Fe | ||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Workability | Because ordinary temperature strength of NASNW400 is lower than that of Type 304, the cold working such as bending is easier than Type 304. | ||

| Weldability | Possible welding methods include shielded metal arc welding, TIG, MIG, and resistance welding. ENiCu-7 welding consumable should be used for TIG and MIG welding. | ||

| Heat Treatment | Solution annealing of NASNW400 is normally performed at the temperature range from 700 to 900°C followed by being quenched in water or rapidly cooled by other means. | ||

| Pickling | It should be noted that descaling of NASNW400 is somewhat difficult in comparison with Type 304. | ||

| Applications | Chemical plants, Fluorine-related equipment, Oil and gas extraction, Heat exchangers, Sacrificial anode. | ||

Grade/Standard

| Nippon Yakin Grade | JIS G 4902 | ASTM B127 | EN |

|---|---|---|---|

| NASNW400 | NW4400 | UNS N04400 | — |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cu | Fe | |

|---|---|---|---|---|---|---|---|---|

| Specification (NW4400) | ≤0.30 | ≤0.50 | ≤2.00 | ≤0.024 | ≤0.020 | ≥63.00 | 28.00-34.00 | ≤2.50 |

| Specification (UNS N04400) | ≤0.3 | ≤0.5 | ≤2.0 | ≤0.024 | ≤0.02 | ≥63.0 | 28.00-34.0 | ≤2.5 |

Physical Properties

| Density | g/cm³ | 8.8 |

| Specific heat | J/kg·K | 424 (at 20°C) |

| Electrical resistivity | µΩ·cm | 54.7 |

| Thermal conductivity | W/m·K | 23.9 |

| Average coefficient of thermal expansion 10⁻⁶/°C | 20~100°C | 13.6 |

| 20~200°C | 14.1 | |

| 20~300°C | 14.6 | |

| 20~400°C | 15 | |

| Young’s modulus | MPa | 17.8 × 10⁴ |

| Melting range | °C | 1300~1350 |

Mechanical Properties

Mechanical Properties at Room Temperature

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HV) | |||

| Specification (NW4400) | Annealing | ≥195 | ≥485 | ≥35 | — | |

| Specification (UNS N04400) | Annealing | Hot-rolled plate | ≥195 | ≥485 | ≥35 | |

| Cold-rolled sheet | ≥195 | 485~585 | ≥35 | |||

| Example | Annealing | Hot-rolled plate (12mm) | 209 | 513 | 52 | 131 |

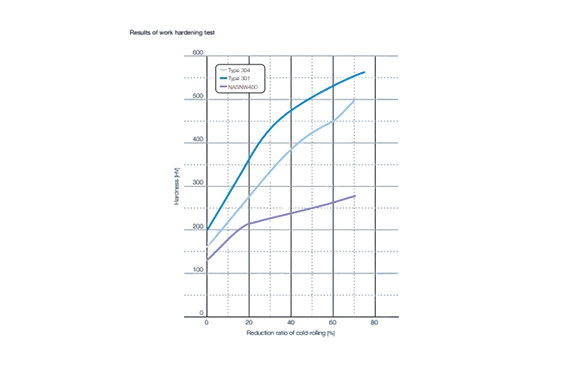

Work Hardening

Because work hardening of NASNW400 is substantially smaller than that of Type 301 and Type 304, bending forming and similar working can be performed easily.

Corrosion Resistance

Acid Resistance

| Alloy | 5% | 10% | 20% | 40% | 60% | 80% |

|---|---|---|---|---|---|---|

| SUS316L | 1.67 | 4.69 | 71.91 | 764.0 | 704.5 | 33.74 |

| NAS64 | <0.01 | 0.02 | 1.07 | 191.9 | 1054 | 60.72 |

| NAS254N | 0.02 | 0.05 | 1.02 | 2.11 | 2.16 | 7.76 |

| NASNW400 | 0.28 | 0.27 | 0.20 | 0.16 | 0.14 | 0.80 |

Test time: 24h

Corrosion rate in boiling sulfuric acid (mm/y)

| Alloy | 5% | 10% | 20% | 40% |

|---|---|---|---|---|

| SUS316L | 8.19 | 24.61 | 178.9 | 3129 |

| NAS64 | 0.35 | 1.65 | 17.68 | 3829 |

| NAS254N | 1.17 | 3.30 | 7.90 | 24.65 |

| NASNW400 | 0.21 | 0.36 | 0.53 | 1.23 |

Test time: 24h

Corrosion rate in hydrochloric acid at 80°C (mm/y)

| Alloy | 0.1% | 1% | 2% | 3% |

|---|---|---|---|---|

| SUS316L | 0.91 | 2.73 | 6.75 | 14.98 |

| NAS64 | 0.01 | 0.01 | 12.94 | 30.51 |

| NAS254N | 0.01 | 0.02 | 0.01 | 0.09 |

| NASNW400 | 0.34 | 0.40 | 0.46 | 1.63 |

Test time: 24h

Corrosion rate in boiling formic acid (mm/y)

| Alloy | 20% | 40% | 60% | 80% |

|---|---|---|---|---|

| SUS316L | 0.15 | 0.49 | 0.70 | 1.22 |

| NAS64 | 0.04 | 0.11 | 0.23 | 0.30 |

| NAS254N | 0.01 | 0.05 | 0.08 | 0.10 |

| NASNW400 | 0.05 | 0.08 | 0.15 | 0.20 |

Test time: 24h

Reference

| Alloy | JIS | UNS No. | Chemical Composition |

|---|---|---|---|

| SUS316L | SUS316L | S31603 | 17Cr-12Ni-2Mo |

| NAS64 | SUS329J4L | S32506 | 25Cr-6.5Ni-3.3Mo-0.17N |

| NAS254N | SUS836L | S32603 | 23Cr-25Ni-5.5Mo-0.2N |

| NASNW400 | NW4400 | N04400 | 66Ni-32Cu-1Fe |

Workability

Because ordinary temperature strength of NASNW400 is lower than that of Type 304, the cold working such as bending is easier than Type 304.

Weldability

Possible welding methods include shielded metal arc welding, TIG, MIG, and resistance welding. ENiCu-7 welding consumable should be used for TIG and MIG welding.

Heat Treatment

Solution annealing of NASNW400 is normally performed at the temperature range from 700 to 900°C followed by being quenched in water or rapidly cooled by other means.

Pickling

It should be noted that descaling of NASNW400 is somewhat difficult in comparison with Type 304.

Applications

Chemical plants, Fluorine-related equipment, Oil and gas extraction, Heat exchangers, Sacrificial anode.

Related Products

-

Nippon Yakin Kogyo NAS22-3 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS64 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS601 Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS21-6 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS42 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NASNM17 Non-Magnetic Alloys