Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASH330 Heat Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NASH330

NASH330 (UNS N08330)

Heat-Resistant Nickel Alloy

NASH330 is a heat-resistant nickel alloy with excellent high-temperature strength, corrosion resistance, and metallurgical stability. In particular, it provides superior resistance to carburization and nitridation. Because it has a fully austenitic microstructure, it displays good workability. Nippon Yakin supplies NASH330 in plate, sheet, and strip forms.

| Chemical Composition | 33Ni-18Cr-1.2Si | ||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Workability | The hot workability and cold workability of NAS-H330 are similar to those of conventional austenitic stainless steels. For hot working, a starting temperature of 1230°C and finishing temperature of 850°C are suitable. Cold workability is similar to that of conventional austenitic stainless steels. Work hardening tends to be slightly lower. Bending, drawing, and similar working are possible. | ||

| Weldability | NAS-H330 can be welded by TIG, MIG, and shield metal arc welding in the same manner as with conventional standard austenitic stainless steels. Manufacturers frequently use AWS ERNiCr-3 welding electrodes. | ||

| Heat Treatment | Heat treatment of NAS-H330 is similar to that of conventional austenitic stainless steels. The typical heat treatment is as follows: Solution heat treatment: 1040-1120°C.The solution heat treatment process performs carbide dissolution and strain removal. | ||

| Pickling | Pickling is performed with a nitric hydrofluoric acid solution or aqua regia solution (nitric hydrofluoric acid solution) in the same manner as with standard austenitic stainless steels. | ||

| Features | NAS-H330 is used mainly in high temperature carburizing or nitriding atmospheres. It is most suitable for application in the 815-1150°C temperature range. | ||

Steel Grade/Standard

| Nippon Yakin Grade | JIS | ASTM B536 |

|---|---|---|

| NASH330 | — | UNS N08330 |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Cu | Pb | Sn | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification (UNS N08330) | ≤0.08 | 0.75-1.50 | ≤2.00 | ≤0.03 | ≤0.03 | 34.0-37.0 | 17.0-20.0 | ≤1.00 | ≤0.005 | ≤0.025 | Bal. |

Physical Properties

| Density [g/cm³] | 7.98 |

| Specific heat [J/kg•K] | 480 |

| Electrical resistivity [μΩ•cm] | 100 |

| Thermal conductivity [W/m•K] | 11.9 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 25–200°C 15.3 |

| 25–400°C 16.0 | |

| 25–600°C 16.5 | |

| 25–800°C 17.1 | |

| Young’s modulus [MPa] | 19.6 × 10⁴ |

| Magnetism [μ] | None |

| Melting range [°C] | 1340–1395 |

Mechanical Properties

Mechanical Properties at Room Temperature

| 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HRBW] | |

|---|---|---|---|---|

| Specification ASTM B536 (UNS N08330) | ≥207 | ≥483 | ≥30 | — |

| Examples Hot-rolled plate (9.5mm) | 253 | 549 | 46 | 78 |

| Examples Cold-rolled sheet (3mm) | 269 | 545 | 45 | 76 |

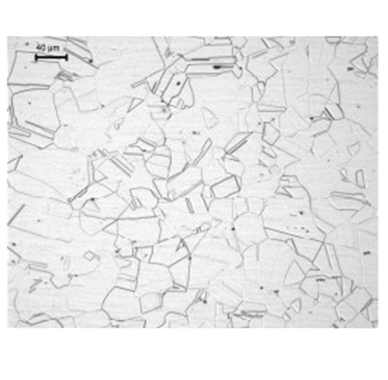

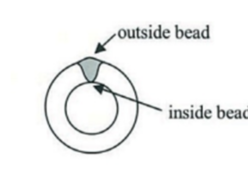

Microstructure

| Specification ASTM B536 (UNS N08330) | Heat treatment |

|---|---|

| — | ≥1040°C |

Typical microstructure of NASH330

Typical microstructure of NASH330

Grain Size Number = 5

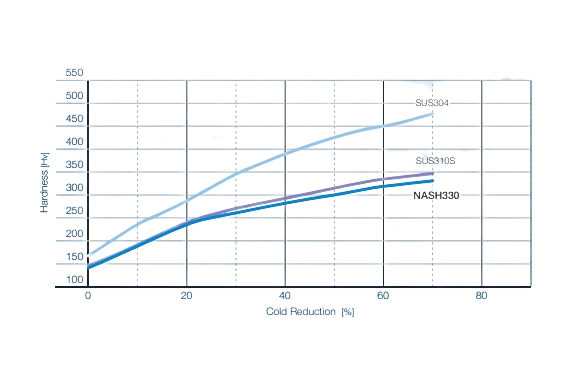

Work Hardening Property

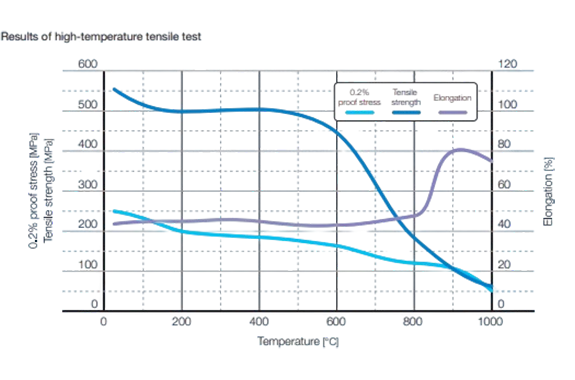

High Temperature Strength

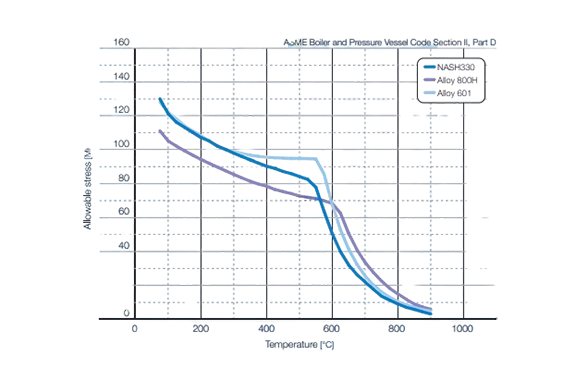

Allowable Stress

Workability

The hot workability and cold workability of NASH330 are similar to those of conventional austenitic stainless steels. For hot working, a starting temperature of 1230°C and finishing temperature of 980°C are suitable. Cold workability is similar to that of conventional austenitic stainless steels. Work hardening tends to be slightly lower. Bending, drawing, and similar working are possible.

Weldability

You can weld NASH330 using TIG, MIG, and shielded metal arc welding, just as you do with conventional standard austenitic stainless steels. Manufacturers frequently use AWS ERNiCr-3 welding electrodes.

Heat Treatment

Heat treatment of NASH330 is similar to that of conventional austenitic stainless steels. The typical heat treatment is as follows:

Solution heat treatment: 1040–1120°C

Carbide dissolution and strain removal are performed in the above solution heat treatment.

Pickling

Pickling is performed with a nitric-hydrofluoric acid solution or aqua regia solution (nitric-hydrochloric acid solution) in the same manner as with standard austenitic stainless steels.

Features

NASH330 is used mainly in high-temperature carburizing or nitriding atmospheres. It is most suitable for application in the 815–1150°C temperature range.

Applications

Furnace parts, Heat treatment fixtures, Carbonization furnace components.

Related Products

-

Nippon Yakin Kogyo NAS255NM Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASH840 Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS21-6 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS601 Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS185N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS22-3 Controlled Expansion Alloys