Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NAS800H, NAS800T Heat Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NAS800H,NAS800T

NAS800H/800T (UNS N08810/N08811)

Heat-Resistant Nickel Alloy

NAS800H (NCF800H, UNS N08810)/NAS800T (UNS N08811) are nickel-iron-chromium alloys that provide high strength and excellent resistance to oxidation and carburization at high temperatures. Engineers attain high creep strength by controlling crystal grains through high-temperature heat treatment and by precisely managing the carbon, titanium, and aluminum cont Nippon Yakin provides this product in plate, sheet, and strip forms.

| Chemical Composition | [NAS800H]32Ni-20Cr-0.7Ti-0.2Al; | ||

| [NAS800T]32Ni-20Cr-0.5Ti-0.5Al | |||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Workability | Whether for hot working or cold working, NAS800H/800T offer workability similar to austenitic stainless steels.Operators should maintain temperatures between 1200 and 1230°C for hot working, although they can perform light work at temperatures as low as 850°C. To prevent cracks, we recommend avoiding the temperature range between 650 and 800°C. Although cold workability is similar to austenitic stainless steels, work hardening tends to be slightly lower. | ||

| Weldability | You can weld NAS800H/800T using techniques such as TIG, MIG, and shielded metal arc welding, just as with standard austenitic stainless steels. Welders often use AWS ERNiCr-3/AWS ENiCrFe-2 welding rods. | ||

| Heat Treatment | NAS800H/800T exhibit an austenitic structure similar to austenitic stainless steels, and appropriate heat treatment procedures and requirements are similar. Typical heat treatments are as follows: Solution treatment: 1100-1170°C; rapid cooling. For applications requiring creep rupture strength in high temperature environments, the following ASTM B409 heat treatment may be used: Solution treatment: 1121°C minimum (UNS N08810) 1149°C minimum (UNS N08811) | ||

| Properties at High Temperatures | Because of its high nickel and chromium content, NAS800H/800T resist oxidation and carburization at high temperatures. NAS800H/800T are superior to Type 310S and approach NAS800 in resistance to oxidation. Engineers widely use NAS800H/800T in applications requiring heat resistance due to their superior high-temperature strength, which is nearly equal to that of NAS800. These materials do not become brittle from sigma phase precipitation during use. While users generally apply NAS800 at temperatures below 600°C, they recommend NAS800H/800T for applicati requiring superior creep properties at higher temperatures | ||

| Corrosion resistance | NAS800H/800T offer superior corrosion resistance in oxidizing corrosive environments such as nitric acid or nitric acid sulfuric acid. Likewise, they perform well in sodium salt and other molten salt environments, with stress corrosion cracking resistance surpassing standard austenitic stainless steels. | ||

Grade/Standards

| Nippon Yakin Grade | JIS G 4902 | ASTM B409 | EN 10095 |

|---|---|---|---|

| NAS800H | NCF800H | UNS N08810 | — |

| NAS800T | — | UNS N08811 | — |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Cu | Al | Ti | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification (NCF800H) | 0.05–0.10 | ≤1.00 | ≤1.50 | ≤0.030 | ≤0.015 | 30.00–35.00 | 19.00–23.00 | ≤0.75 | 0.15–0.60 | — | Bal. |

| Specification (UNS N08810) | 0.05–0.10 | ≤1.0 | ≤1.5 | — | ≤0.015 | 30.00–35.00 | 19.00–23.00 | ≤0.75 | 0.15–0.60 | — | ≥39.5 |

| Specification (UNS N08811) | 0.06–0.10 | ≤1.5 | — | ≤0.015 | — | 30.00–35.00 | 19.00–23.00 | ≤0.75 | 0.15–0.60 | — | ≥39.5 |

| Specification (EN 1.4876) | ≤0.12 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 30.00–34.00 | 19.00–23.00 | — | 0.15–0.60 | 0.15–0.60 | — |

Physical Properties

| Density [g/cm³] | 8.03 |

| Specific heat [J/kg•K] | 460 |

| Electrical resistivity [μΩ•cm] | 99 |

| Thermal conductivity [W/m•K] | 12.6 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 25–200°C 15.9 |

| 25–400°C 16.8 | |

| 25–600°C 17.3 | |

| 25–800°C 18.1 | |

| Young’s modulus [MPa] | 19.7 × 10⁴ |

| Curie point [°C] | −115 |

| Magnetism [μ] | None |

| Melting range [°C] | 1357–1385 |

Properties at High Temperatures

| Temperature | Thermal conductivity [W/m • K] | Average coefficient of thermal expansion [10⁻⁶/°C] | Young’s modulus [10¹ MPa] |

|---|---|---|---|

| Room temperature | 12.6 | — | 19.7 |

| 100°C | 14.1 | 14.6 | 19.3 |

| 200°C | 16.1 | 15.9 | 18.7 |

| 300°C | 17.8 | 16.4 | 18.0 |

| 400°C | 19.3 | 16.8 | 17.3 |

| 500°C | 20.6 | 17.0 | 16.7 |

| 600°C | 23.2 | 17.3 | 15.9 |

| 700°C | 24.4 | 17.7 | 15.2 |

| 800°C | 25.1 | 18.1 | 14.5 |

| 900°C | 25.9 | 18.3 | 13.8 |

| 1000°C | 26.7 | 18.6 | 13.1 |

Microstructure

| Specification | Heat Treatment | Crystal Grain Size |

|---|---|---|

| NCF800H | 1100–1170°C | No.5 or coarser |

| UNS N08810 | ≥1121°C | No.5 or coarser |

| UNS N08811 | ≥1149°C | No.5 or coarser |

Typical microstructure of NAS800T

Grain size number = 3

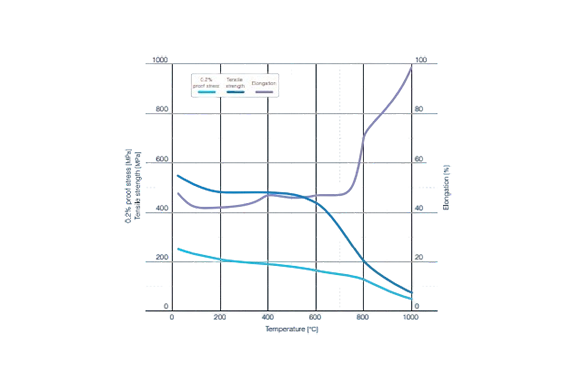

Mechanical Properties

Mechanical Properties at Room Temperature

| 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HV] | |

|---|---|---|---|---|

| Specification (NCF800H) | ≥175 | ≥450 | ≥30 | ≤171 |

| Specification (UNS N08810) | ≥170 | ≥450 | ≥30 | — |

| Specification (UNS N08811) | ≥170 | ≥450 | ≥30 | — |

| Specification (EN 1.4876) | ≥170 | 450–680 | ≥30 | ≤192 |

High-Temperature Strength

Creep Properties

| Heat treatment | Temperature [°C] | Creep rupture strength [MPa] | Creep strength [MPa] |

|---|---|---|---|

| Solution treatment 1150°C | 650 | 228 | 110 |

| 704 | 162 | 54 | |

| 816 | 64 | 22 | |

| 100hr | 700 | — | — |

| 1000hr | — | — | |

| 10000hr | — | — |

Workability

Whether for hot working or cold working, NAS800H/800T offer workability similar to austenitic stainless steels. For hot working, temperatures should be between 1000 and 1230°C, although light work may be done at temperatures as low as 850°C. To prevent cracks, we recommend avoiding the temperature range between 850 and 800°C. Although cold workability is similar to austenitic stainless steels, work hardening tends to be slightly lower.

Weldability

As with standard austenitic stainless steels, NAS800H/800T may be welded using techniques such as TIG, MIG, and shield metal arc welding. AWS ERNiCr-3/AWS ENiCrFe-2 welding rods are often used.

Heat Treatment

NAS800H/800T exhibit an austenite structure similar to austenitic stainless steels, and appropriate heat treatment procedures and requirements are similar. Typical heat treatments are as follows:

- Solution treatment: 1100-1170°C; rapid cooling.

For applications requiring creep rupture strength in high-temperature environments, the following ASTM B409 heat treatment may be used:

- Solution minimum: 1121°C minimum (UNS N08810)

- 1149°C minimum (UNS N08811)

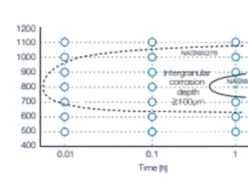

Properties at High Temperatures

Because of its high nickel and chromium content, NAS800H/800T resist oxidation and carburization at high temperatures. NAS800H/800T are superior to Type 310S and approach NAS600 in resistance to oxidation. Offering superior high-temperature strength nearly equal to NAS600, NAS800H/800T are widely used in applications requiring heat resistance, as they do not become brittle due to sigma phase precipitation during use. While NAS800H is generally used at temperatures below 600°C, NAS800H/800T are recommended for applications requiring superior creep properties at higher temperatures.

Corrosion Resistance

NAS800H/800T offer superior corrosion resistance in oxidizing corrosive environments such as nitric acid or nitric acid-sulfuric acid. Likewise, they perform well in sodium salt and other molten salt environments, with stress corrosion cracking resistance surpassing standard austenitic stainless steels.

Applications

- Polyethylene production equipment

- Furnace parts

- Heat treatment fixtures

- Heat exchangers

Related Products

-

Nippon Yakin Kogyo NAS354N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS800 Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS355N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASNW22 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS36 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS630 High Strength Stainless Steels