Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NAS630 High Strength Stainless Steels

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model :NAS630

NAS630 (UNS S17400)

High Strength Stainless Steel

NAS630 is a precipitation hardening type of high strength stainless steel. It has excellent corrosion resistance equivalent to that of 18-8 austenitic stainless steels and also provides high strength equivalent to chromium stainless steels, which have a quench-hardening capacity. NAS630 is used in various parts where high strength is required, such as steel belts, high-strength mechanical parts, etc. Nippon Yakin supplies NAS630 in plate, sheet, and strip forms.

| Chemical Composition | 17Cr-4Ni-4Cu-0.2Nb | ||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Heat Treatment | NAS630 is normally supplied in a solution treated condition. However, in order to obtain the maximum mechanical properties, it is necessary to perform H900 precipitation hardening heat treatment after working. If ductility is required, we recommend using H1150 precipitation hardening heat treatment. In this case, it is possible to perform precipitation hardening heat treatment of the base material, as working is also possible after precipitation hardening. Heat treatment conditions: H900 precipitation hardening: 470-490°C; air cooling H1150 precipitation hardening: 610-630°C; air cooling | ||

| Weldability | Welding of NAS630 can be performed using various welding methods in the same manner as with standard type austenitic stainless steels. Maximum welding efficiency can be obtained by performing normal solution treatment + H900 treatment after welding. | ||

| Pickling | In pickling of comparatively thick scale after solution treatment or hot working, the methods used with austenitic stainless steels can be used. | ||

| Applications | Springs, Press plates, Steel belts, Cutting blade. | ||

Steel Grade/Standard

| Nippon Yakin Grade | JIS | ASTM | EN |

|---|---|---|---|

| NAS630 | SUS630 | UNS S17400 | 1.4542 |

* If following is the EN standard, please consult with Nippon Yakin in advance.

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Cu | Nb | |

|---|---|---|---|---|---|---|---|---|---|

| Specification (SUS630) | ≤0.07 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | 3.00–5.00 | 15.00–17.50 | 3.00–5.00 | 0.15–0.45 |

| Specification (UNS S17400) | ≤0.07 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | 3.00–5.00 | 15.00–17.50 | 3.00–5.00 | 0.15–0.45 |

Physical Properties

| Density [g/cm³] | 7.8 |

| Electrical resistivity [μΩ•cm] | 98 |

| Thermal conductivity [W/m•K] | 13.7 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 0–100°C 10.8 |

| 0–400°C 11.3 | |

| Young’s modulus [MPa] | 19.6 × 10⁴ |

| Magnetism | Ferromagnetic |

| Melting range [°C] | 1430–1477 |

Mechanical Properties

| Heat treatment | Thickness [mm] | Proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HBW] |

|---|---|---|---|---|---|

| ASTM A693 UNS S17400 | 0.38–102 | ≥11105 | ≥1235 | ≥15 | ≥363 |

| NAS630 H900 treatment | 4.76–15.88 | ≥1170 | ≥2310 | ≥21 | 269–372 |

| NAS630 H1150 treatment | — | 762 | ≥1240 | ≥30 | 311 |

| NAS630 Solution treatment | — | — | — | — | — |

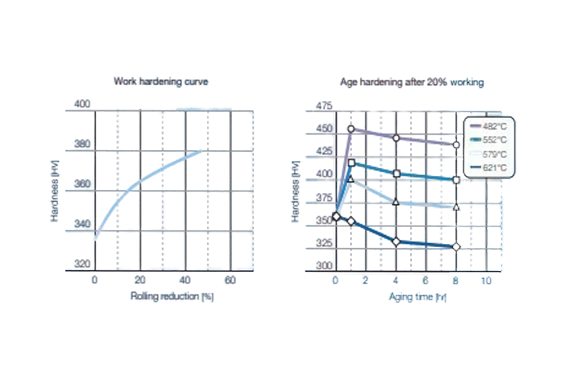

Work Hardening and Age Hardening

Corrosion Resistance

Measurements of pitting potential conformed to JIS G 0577 (2005) (test solution: 1600 mL NaCl solution, 30°C)

| Heat treatment | Potential (VC=10) | Potential (VC=100) |

|---|---|---|

| NASH630 Solution treatment | 0.115 | 0.124 |

| NASH630 H900 treatment | 0.124 | — |

| NASH630 H1150 treatment | 0.087 | 0.095 |

Heat Treatment

NAS630 is normally supplied in a solution-treated condition. However, to obtain the maximum mechanical properties, it is necessary to perform H900 precipitation hardening heat treatment after working. If difficulty is required, we recommend using H1150 precipitation hardening heat treatment.

[Heat treatment conditions]

- H900 precipitation hardening: 470–490°C; air cooling

- H1150 precipitation hardening: 610–630°C; air cooling

Weldability

Welding of NAS630 can be performed using various welding methods in the same manner as with standard type austenitic stainless steels. ER630 welding rods, which have the same composition, are frequently used.

Pickling

In pickling of comparatively thick scale after solution treatment or hot working, the methods used with austenitic stainless steels can be used.

Applications

- Springs

- Press plates

- Steel belts

- Cutting blades

Related Products

-

Nippon Yakin Kogyo NASNW276 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS74N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS36 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NASPC Soft Magnetic Alloys

-

Nippon Yakin Kogyo NAS42 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS75N Corrosion Resistant Alloys