Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASXM-19 High Strength Stainless Steels

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NASXM-19

NASXM-19 (UNS S20910)

High Strength, High Corrosion Resistance Stainless Steel

NASXM-19 is a nitrogen-strengthened austenitic stainless steel with excellent corrosion resistance. In comparison with Type 316L, NASXM-19 provides higher corrosion resistance and higher strength. Nippon Yakin supplies this product in plate, sheet, and strip forms.

| Chemical Composition | 21Cr-12Ni-5Mn-2Mo-0.2Nb-0.2V-0.3N | ||

Product shape |  Coil Coil |  Sheet Sheet |

|

| Workability | Hot and cold workability are substantially the same as other austenitic stainless steels. However, in both hot working and cold working, the fact that this is a high strength material must be considered. | ||

| Weldability | You can weld it using TIG, MIG, and shielded metal arc welding, just as you would with standard austenitic stainless steels. Frequently, use ER209 welding rods, which have the same composition.Not only are ER209 welding rods frequently used, **but they also** have the same composition. | ||

| Heat Treatment | Solution annealing of NASXM-19 is normally performed at the temperature range from 1065 to 1120°C followed by being quenched in water or rapidly cooled by other means. | ||

| Pickling | A mixture of nitric acid and fluoric acid is used in pickling. However, since descaling is more difficult compared to Type 304, first immerse the material in alkali before acid pickling, and, if possible, use shot blasting for better results. | ||

| Applications | Chemical plants, Spent nuclear fuel containers (casks). | ||

Steel Grade/Standard

| Nippon Yakin Grade | JIS | ASTM |

|---|---|---|

| NASXM-19 | — | UNS S20910 |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Mo | Nb | V | N | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification (UNS S20910) | ≤0.06 | ≤0.75 | 4.00–6.00 | ≤0.040 | ≤0.030 | 11.5–13.5 | 20.5–23.5 | 1.50–3.00 | 0.10–0.30 | 0.10–0.30 | 0.20–0.40 |

Physical Properties

| Density [g/cm³] | 7.88 |

| Specific heat [J/kg · K] | 487 |

| Electrical resistivity [μΩ · cm] | 81 |

| Thermal conductivity [W/m · K] | 13.2 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 24–100°C 15.8 |

| 24–200°C 16.4 | |

| 24–300°C 16.9 | |

| 24–400°C 17.3 | |

| Young’s modulus [MPa] | 19.8 × 10⁴ |

| Magnetism | None |

| Melting range [°C] | 1380–1406 |

Mechanical Properties

| Specification | 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HRBW] |

|---|---|---|---|---|

| Hot-rolled plate (UNS S20910) | 380 | 690 | 235 | 5241 |

| Cold-rolled sheet (UNS S20910) | 415 | 725 | 230 | 100 |

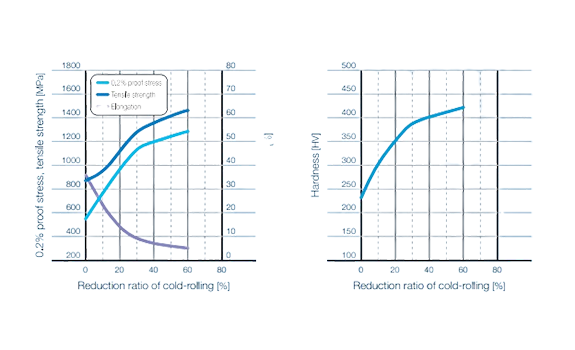

Work Hardening

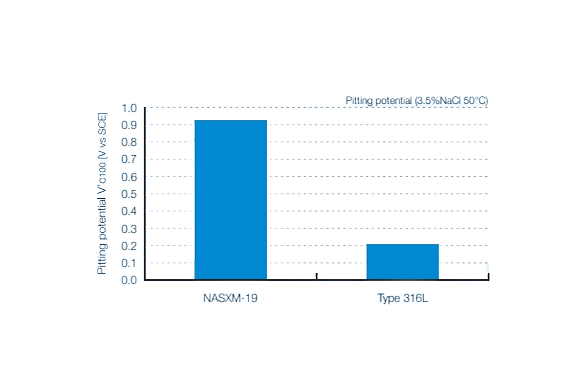

Corrosion Resistance

NASXM-19 possesses higher corrosion resistance than Type 316L.

Workability

Hot and cold workability are substantially the same as other austenitic stainless steels. However, in both hot working and cold working, the fact that this is a high-strength material must be considered.

Weldability

You can weld using TIG, MIG, and shielded metal arc welding in the same way as with standard austenitic stainless steels. Frequently, welders use ER209 rods, which have the same composition.

Heat Treatment

To perform solution annealing of NASXM-19, heat it to a temperature range of 1065 to 1120°C, then quench it in water or rapidly cool it by other means.

Pickling

Use a mixture of nitric acid and hydrofluoric acid for pickling. However, since descaling is more difficult compared to Type 304, immerse the material in alkali before acid pickling, and, if possible, apply shot blasting for better effectiveness.

Applications

- Chemical plants

- Spent nuclear fuel containers (casks)

Related Products

-

Nippon Yakin Kogyo NASNW276 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS42 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NASNW400 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS825 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASNM17 Non-Magnetic Alloys

-

Nippon Yakin Kogyo NAS355N Corrosion Resistant Alloys

Plate

Plate