Showa Kikai Shoji

Showa Kikai Shoji Short Link Chain Conveyor

Made in Japan

Manufacturer: Showa Kikai Shoji

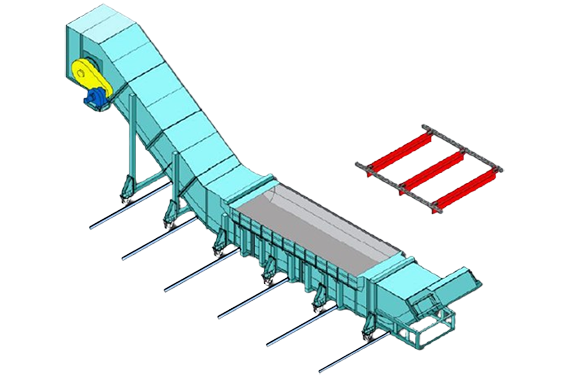

Type: Water-sealed Chain Conveyor

Features:

- This is a scraper conveyor with a water tank, mainly used for transporting ash from coal boilers.

- It uses SKS short-link chains, making it suitable for harsh environments.

- Designed to transport highly abrasive materials, this conveyor offers excellent durability.

- It features a simple yet robust structure, based on SKS’s years of experience.

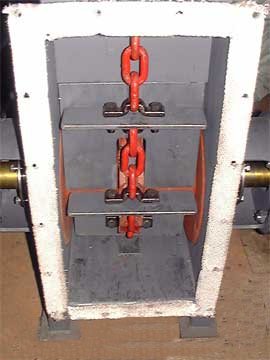

- The connection between the SKS chain and scraper uses shackles, allowing for easy replacement of damaged parts.

Examples of conveyed materials:

Molten slag, metal, bottom ash (coal combustion ash), municipal waste incineration ash, wood chip combustion ash, etc.

Example of chain and scraper configuration:

| Standard equipment specifications | |

|---|---|

| Type | Water-sealed chain conveyor |

| Apparent specific gravity | Average 1.0 ~ 3.0 (tons/m³) |

| Conveying capacity | Max:25(t/h) |

| Particle size | Average from 10mm to 600mm |

| Conveying speed | 0.2 ~ 5.0 (m/min) |

| Inclination angle | Horizontal to a maximum of 50 degrees |

| Chain | SR1964・SR2280・SR2590・SR2892・SR30108など |

| Machine length | Horizontal Min:8,000(mm) Max:25,000(mm) |

| Lifting height Min:2,000(mm) Max:20,000(mm) | |

| Drive system or Drive method | (Standard) Roller chain system |

| Electric motor | (Standard) Cyclo reducer 1.5kW to 30kW |

– Remarks –

- The conveyor’s width and length can be set arbitrarily. The design will be tailored to the conveying capacity.

- When used under a boiler, the upper part of the side plates (left and right) can be opened and closed to move the conveyor.

- To improve wear resistance, basalt material and wear-resistant materials can be used for parts such as the bottom plate.

- To ease the work of chain tension adjustment, hydraulic and jack-type take-up devices are also available.

Example of use

Type | Water-sealed double chain conveyor |

Features:

- Water can be filled into the conveyor.

- Supports widths from 400mm to 1000mm.

- Utilizes two types of SKS chains: plate chain and short-link chain.

Conveyed materials:

- Urban waste incineration ash.

- Wood chip combustion ash.

- Dust under boilers.

- Dust under gas cooling chambers.

- Coal combustion ash.

Features:

- Water can be filled into the conveyor.

- Supports widths of 1000mm or more.

- Uses SKS-manufactured short-link chain.

- Equipped with casters for conveyor movement.

Conveyed materials:

- Incineration ash from melting furnaces.

- Molten metal.

- Molten slag.

- Industrial waste incineration ash.

- Other bulky materials (size 300~500mm)

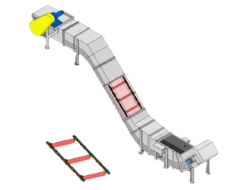

Type | Double chain conveyor |

Features:

- Can be installed in tight spaces due to Σ shape.

- Customizable loading and unloading positions.

- Supports widths from 400mm to 1300mm.

- Uses SKS-manufactured short-link chain.

Conveyed materials:

- Cement.

- Coal.

- Limestone.

- Dust from collection systems and other materials.

Type | C-Type Double Chain Conveyor |

Features:

- Used for recovering dropped material from belt conveyors.

- Supports widths from 400mm to 1300mm.

- Automatic tensioning (counterweight system).

- Uses SKS-manufactured short-link chain.

Conveyed materials:

- Cement.

- Coal (powdered coal).

- Limestone.

- Dust from collection systems (EP and MC dust)

Type | Z-Type Double Chain Conveyor |

Features:

- Compact installation, fits in a small space.

- Minimum machine width of 300mm.

- Utilizes two types of chains: SKS-manufactured short-link chain and plate chain.

Conveyed materials:

- Urban waste incineration ash.

- Coal (powdered coal).

- Limestone.

- Cement.

- Dust from collection systems (EP and MC dust)

Type | Vertical Z-Type Center Chain Conveyor |

Features:

- Compact installation, fits in a small space.

- Supports widths from 150mm to 300mm.

- Uses SKS-manufactured short-link chain.

Conveyed materials:

- Dust from collection systems (EP and MC dust).

- Coal (powdered coal).

- Limestone.

- Cement.

Related Products

-

Showa Kikai Shoji SR Series Wear-Resistant and High-Strength Wear-Resistant Conveyor Chain

-

Showa Kikai Shoji Shackle And Connector

-

Showa Kikai Shoji Simple Wastewater Treatment System

-

Showa Kikai Shoji Chain (Without Heat Treatment) With Strength Guarantee

-

Showa Kikai Shoji Z-Type Bucket Conveyor

-

Showa Kikai Shoji Scraper Conveyor