Manufacturer: Sanshu Sangyo Co., Ltd.

Model: EC Series

Tobacco leaf dryer

Environmentally Friendly Container Bulk Dryer

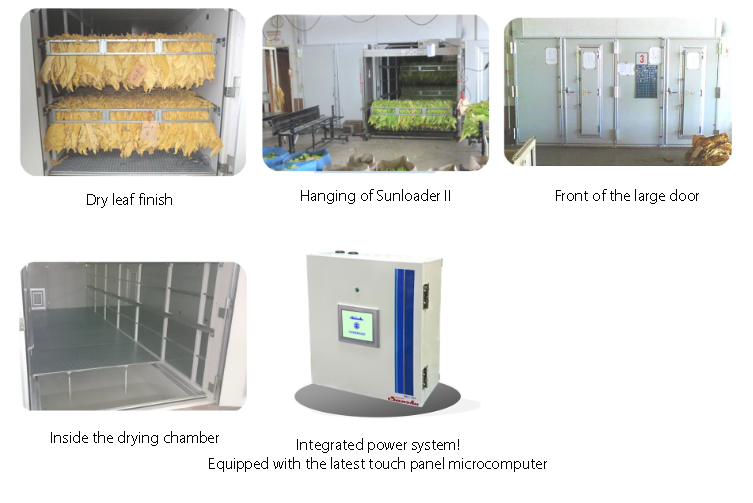

Main unit side (and microcomputer bulk device)

Main unit side (and microcomputer bulk device)

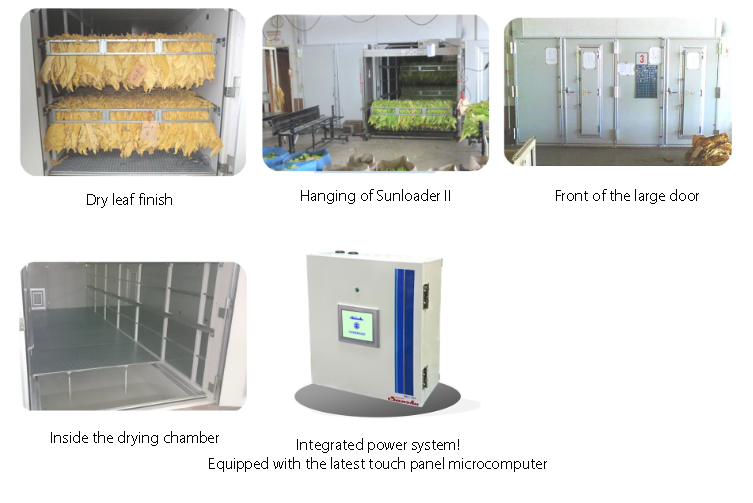

Inside the drying chamber

Inside the drying chamber

Development concept of the environmentally friendly container bulk dryer

1) Development Concept

- To reduce the environmental impact in tobacco leaf drying and better preserve the Earth’s environment, therefore, the machine developers aimed to reduce fuel consumption by more than 30% compared to conventional machines.

2) Energy-saving Performance

- It enables a reduction in fuel consumption of over 30%. (Passed the Tobacco Cultivation Material Commissioned Test in FY 2016).

Features

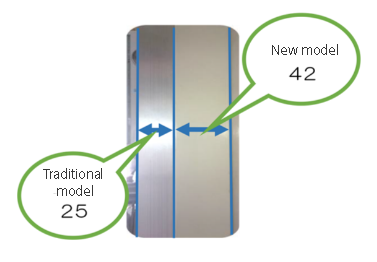

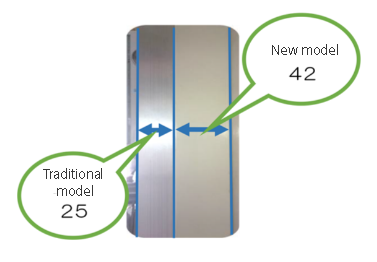

1.Significant improvement in insulation performance

①The panel thickness increases from the previous 25mm to 42mm.

As a result, insulation performance improves significantly by using color steel plates for the outer surface, injecting high-density foam polyurethane inside, and replacing the traditional aluminum frame with a resin frame.

As a result, insulation performance improves significantly by using color steel plates for the outer surface, injecting high-density foam polyurethane inside, and replacing the traditional aluminum frame with a resin frame.

②In addition, insulation panels are applied to the bottom plate to prevent heat loss from the foundation.

As a result, the heat loss to the foundation section is significantly reduced.

As a result, the heat loss to the foundation section is significantly reduced.

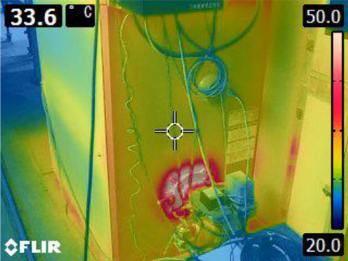

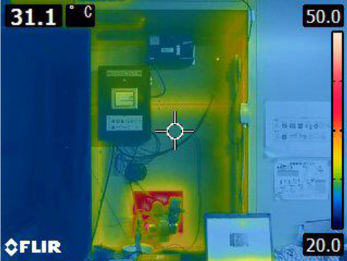

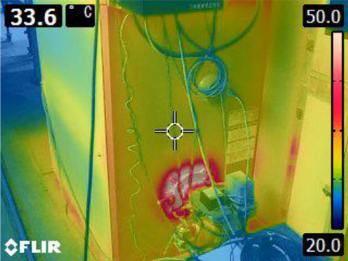

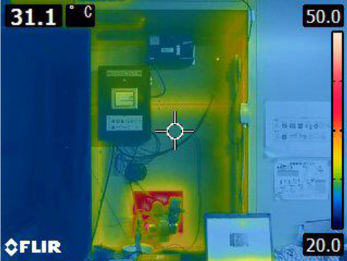

③Thermography image of the hot air generator during drying

※ The higher the temperature, the stronger the red color appears.

Traditional dryer

Traditional dryer

(Insulation material: Glass wool)

EC-type dryer

EC-type dryer

Insulation material: Gypsum board + foam polyurethane

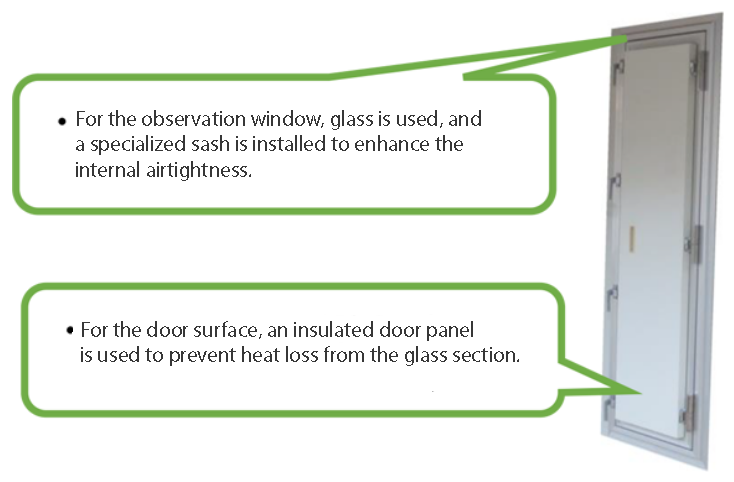

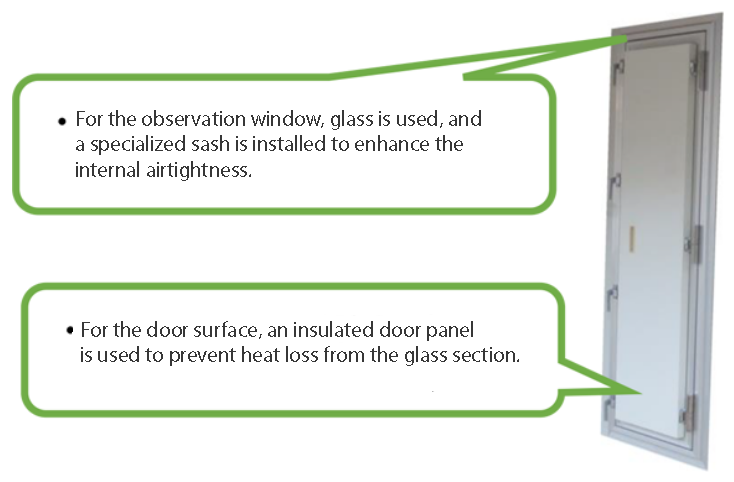

④To prevent heat loss from the observation window, specialized sashes and insulation panels have been used.

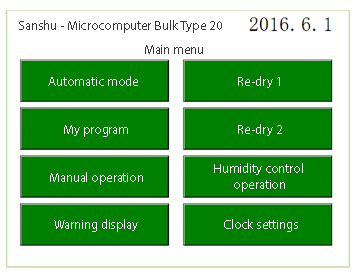

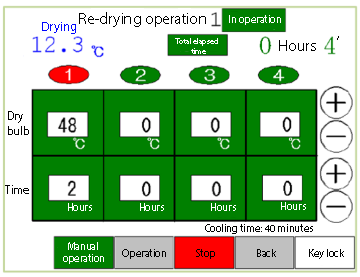

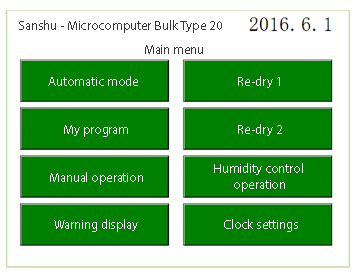

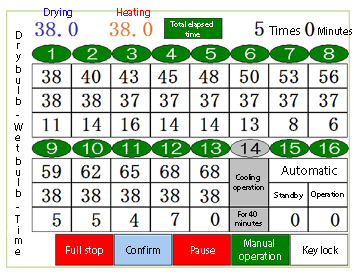

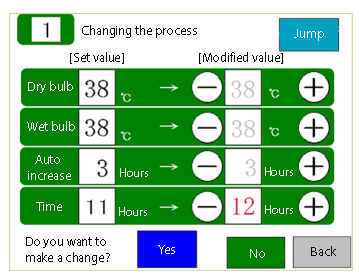

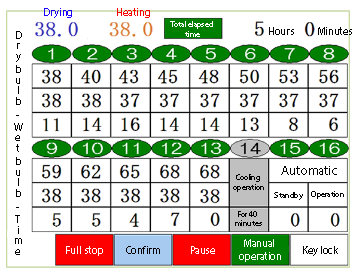

2. New Microcomputer Bulk Type 20 (Touch Panel Type)

Building on the user-friendliness of the Microcomputer Type 5, we aimed for an even higher quality finish.

Making the tobacco leaf production process more enjoyable and simpler!

Equipped with a 5.7-inch high-definition touch panel

Equipped with a 5.7-inch high-definition touch panel

Features of the New Microcomputer Bulk

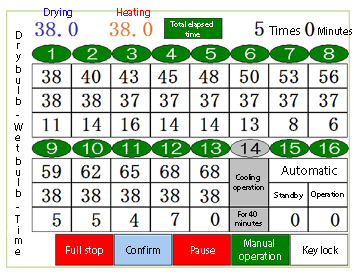

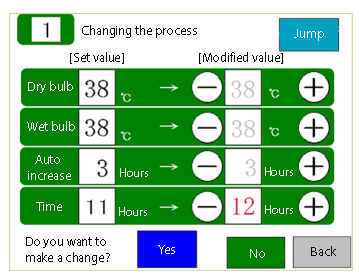

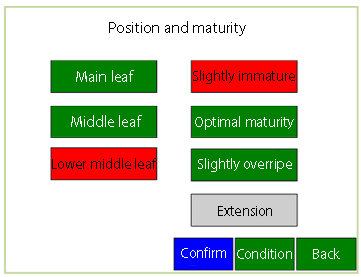

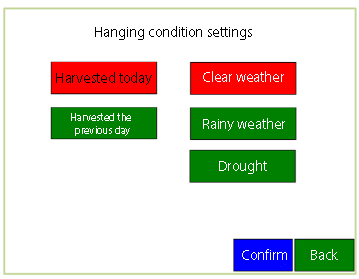

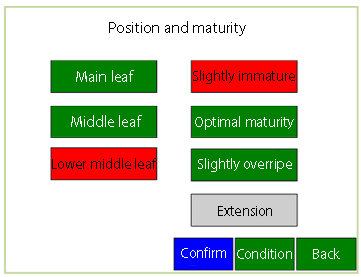

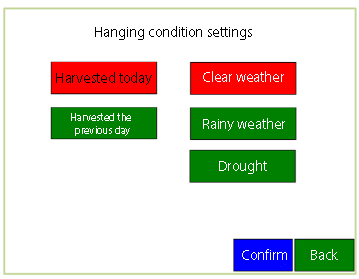

Part 1. By adding new hanging conditions, we aimed to improve the finishing quality.

Reducing operational effort

Reducing operational effort

Towards a more ideal finish

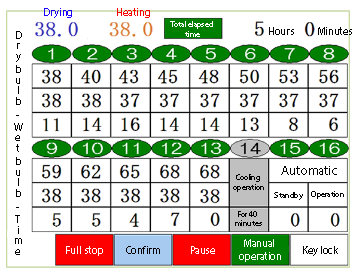

Part 2. Simple design for intuitive operation Focused on essential information only

Focused on essential information only

Emphasized user-friendly operation for seamless navigation

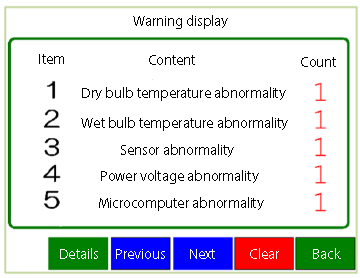

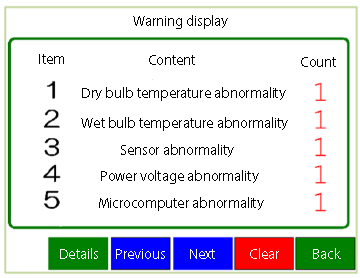

Part 3. Reliable support to prevent accidental mistakes

Minimizes operational errors, with immediate alert notifications

Minimizes operational errors, with immediate alert notifications

Additionally, optimizes the movement of the damper

With new features, both finishing quality and fuel efficiency are improved

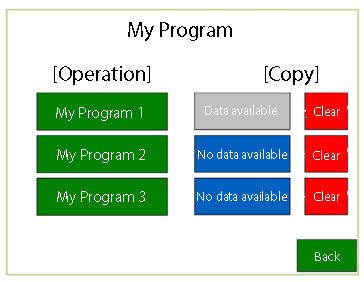

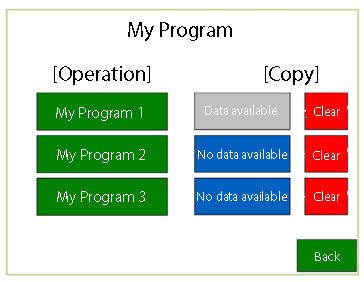

Part 4. Save up to three personalized custom programs

Expert drying methods

Expert drying methods

Easily saved with simple copying

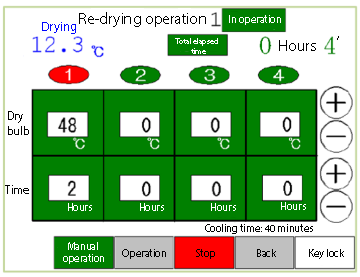

Part 5. Easily start re-drying or humidity control operation when overly damp

A dedicated program menu screen has been provided

A dedicated program menu screen has been provided

Effortless one-touch startup without hesitation

Specifications of the New Microcomputer Bulk Model

| Name / Model | Microcomputer Bulk 20 / MC-0101 |

|---|

| Monitor panel | 5.7-inch TFT color LCD

Touch switch method |

|---|

| Function / Display / Settings | Drying Modes: Automatic, My Program, Re-dry, Humidity control, Manual Display/Settings: Main menu, In operation, Change screen, Clock Settings: Touchscreen settings Alarms: Dry bulb, Wet bulb, Sensor, Power, Microcomputer abnormality |

|---|

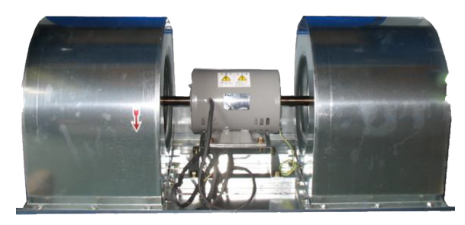

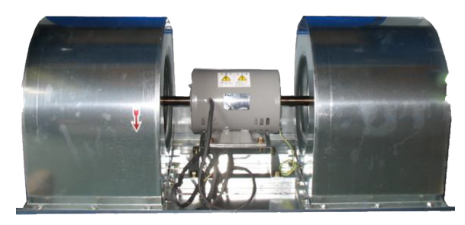

3. Equipped with a double-inlet multi-blade blower (Sirocco fan)

- A quiet multi-blade blower (Sirocco fan) is used, and it operates more quietly compared to traditional axial flow fans.

- The three-phase induction motor meets energy-saving standards, compatible with high-efficiency motors (IE2, IE3).

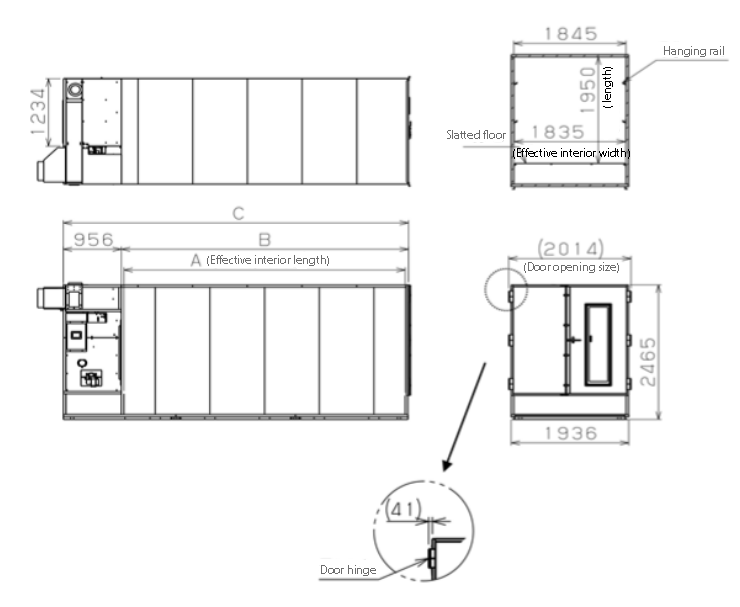

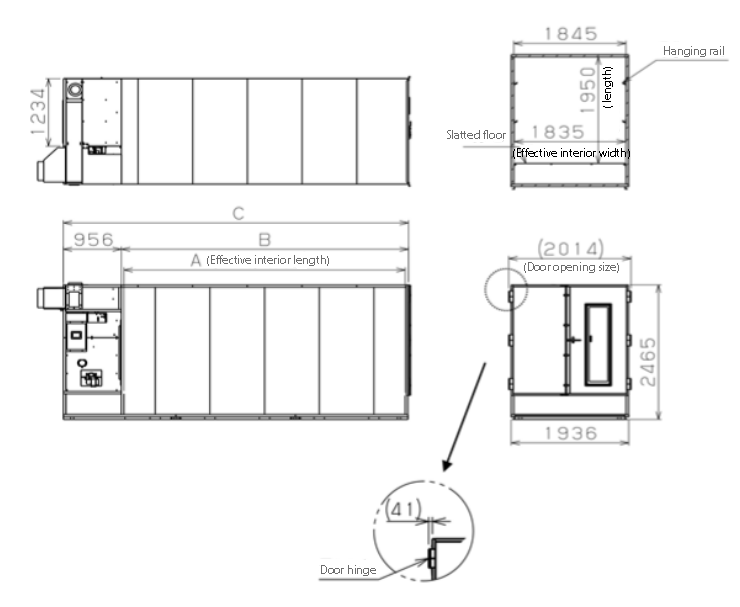

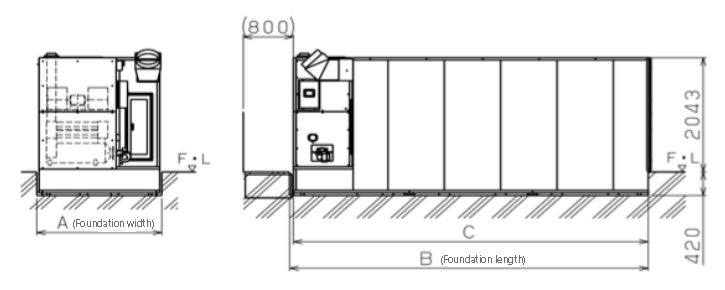

External dimensions drawing of the environmentally friendly container bulk dryer

Dimensions of each part of the dryer

| Drying chamber floor area | Dimensions A

(mm) | Dimensions B

(mm) | Dimensions C

(mm) |

|---|

| 6.6㎡model (2.0 tsubo) | 3,730 | 3,814 | 4,783 |

| 8.3㎡model (2.5 tsubo) | 4,630 | 4,714 | 5,683 |

| 9.9㎡model (3.0 tsubo) | 5,560 | 5,644 | 6,613 |

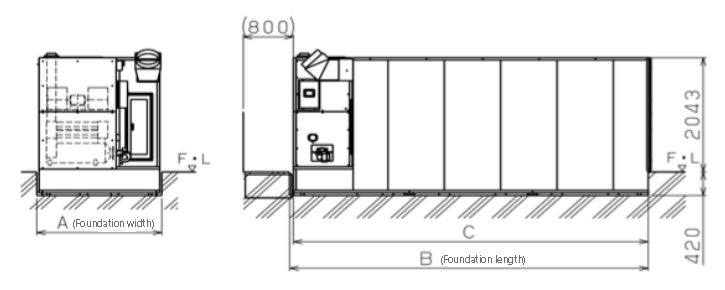

Foundation dimensions of the dryer

| Drying chamber floor area | Dimensions A

(mm) | Dimensions B

(mm) | Dimensions C

(mm) |

|---|

| 6.6㎡model (2.0 tsubo) | 2,000 | 4,830 | 4,775 |

| 8.3㎡model (2.5 tsubo) | 2,000 | 5,730 | 5,675 |

| 9.9㎡model (3.0 tsubo) | 2,000 | 6,660 | 6,613 |

Specifications of the Environmentally Friendly Container Bulk Dryer

| Model Type | EC30-CUSD-100-6.6-2-P-MC | EC30-CUSD-120-8.3-2-P-MC | EC30-CUSD-120-9.9-2-P-MC |

|---|

| Drying chamber | Effective floor area | 6.8m2 | 8.5m2 | 10.2m2 |

|---|

Effective floor area of

the machinery room | 1.1㎡ |

|---|

Dimensions (internal)

Width×Length×Height | 1,835×3,730×1,950mm | 1,835×4,630×1,950mm | 1,835×5,560×1,950mm |

|---|

| Number of hanging levels | 2 levels |

|---|

| Name of hanging equipment | Easy Needle Rack with 32 Frames | Easy Needle Rack with 40 Frames | Easy Needle Rack with 48 Frames |

|---|

| Hanging capacity | 900kg | 1,150kg | 1,350kg |

|---|

| Generator | Blower | Model Type | Double-inlet centrifugal multi-blade blower (1 unit) |

|---|

| Rated output | Single-phase 200V – 750W

Three-phase 200V – 1.5kW |

|---|

| Airflow volume | 100 ㎥/min | 120 ㎥/min |

|---|

| Static pressure | Single-phase 200V – 33mmAq

Three-phase 200V – 40mmAq | Single-phase 200V – 28mmAq

Three-phase 200V – 38mmAq |

|---|

| Electric current | Single-phase 200V – 7.5A

Three-phase 200V – 5.5A | Single-phase 200V – 9.3A

Three-phase 200V – 6.3A |

|---|

| Burner | Model Type | Gun-type burner |

|---|

| Fuel used | Kerosene JIS K2203-1 |

|---|

| Fuel consumption | 3.2L/H (0.85G/H) |

|---|

| Motor output | 200V 20W 0.35A/0.4A(60Hz/50Hz) |

|---|

| Ignition device | Primary side: 200V 0.9A

Secondary side: 15KV 23mA |

|---|

| Control device | Control by Microcomputer Bulk (Microcomputer system)

① Dry bulb control: ON-OFF control by burner

② Wet bulb control: PID control by automatic damper |

|---|

| Safety device | Burner circuit shutdown and alarm system using protect relays and high limit (liquid expansion type) |

|---|

| Total input | Single-phase 200V: 1.7kW 8.8A

Three-phase 200V: 1.6kW 6.8A | Single-phase 200V: 2.0kW 10.6A

Three-phase 200V: 1.9kW 7.6A |

|---|

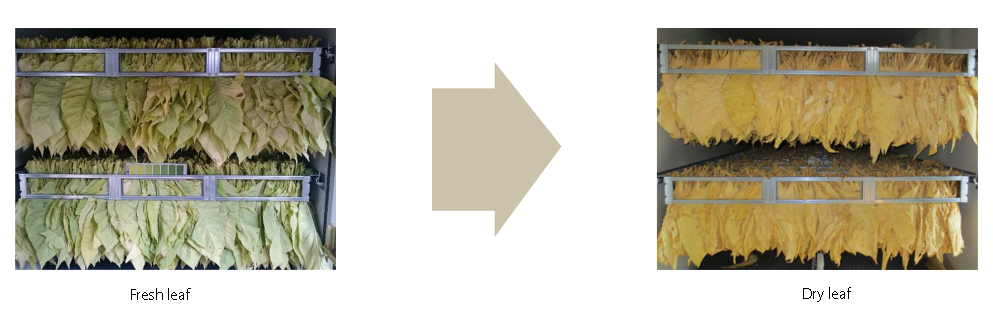

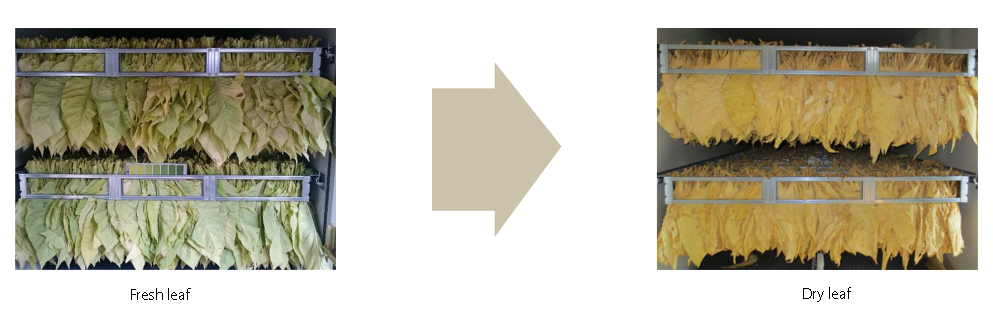

Compatibility between fresh leaf, dry leaf photos, and the hanging device.

It’s compatible with the standard hanging device, so it can be used as usual.

Large Container Bulk Dryer

- The drying chamber and hot air generator are insulated with 42mm panels! The traditional model used 25mm.

- Fuel consumption during drying can be reduced by 30%!

- A new type has been developed that can utilize existing foundations!

- Reduced packing materials and coatings. Countermeasure against foreign matter contamination!

- Equipped with an easy-to-use touch panel type microcomputer bulk dryer.

Standard specifications of the environmentally friendly container bulk large dryer

| Model Type | EC30-JCD250-13.2-2-P-MC | EC30-JCD250-16.5-2-P-MC | EC30-JCD340-20-2-P-MC |

|---|

| Drying chamber | Effective floor area | 13.2㎡ | 16.5㎡ | 19.8㎡ |

|---|

Effective floor area of

the machinery room | 3.0㎡ |

|---|

Dimensions (internal)

Width×Length×Height | (1,835×2)×3,730× 1,916mm | (1,835×2)×4,630× 1,916mm | (1,835×2)×5,560× 1,916mm |

|---|

| Number of hanging levels | 2 levels |

|---|

| Name of hanging equipment | Easy Needle Rack with 64 Frames | Easy Needle Rack with 80 Frames | Easy Needle Rack with 96 Frames |

|---|

| Hanging capacity | 2,000kg | 2,600kg | 3,100kg |

|---|

Hot

air

generator | Blower | Model Type | Three-phase induction motor direct-coupled, rear-mounted static blade axial flow fan (2 units) |

|---|

| Rated output | Three-phase 200V-0.75kW×2 | Three-phase 200V-1.5kW×2 | Three-phase 200V-2.0kW×2 |

|---|

| Airflow volume | 125m3/min × 2 | 145m3/min × 2 | 180m3/min × 2 |

|---|

| Static pressure | 147Pa(15mmAq) | 196Pa(20mmAq) |

|---|

| Power supply | Three-phase 200V – 4.0A × 2 | Three-phase 200V―6.0A×2 | Three-phase 200V―8.0A×2 |

|---|

| Burner | Model Type | Gun-type burner |

|---|

| Fuel used | Kerosene JIS K2203-1 |

|---|

| Fuel consumption | 5.7L/h(1.5G/h) |

|---|

| Motor output | 200V 40W 0.4A |

|---|

| Ignition device | Primary side: 200V 0.9A

Secondary side: 15KV 23mA |

|---|

| Control device | Control by Microcomputer Bulk (Microcomputer system)

① Dry bulb control: ON-OFF control by burner

② Wet bulb control: PID control by automatic damper |

|---|

| Safety device | Burner circuit shutdown and alarm system using protect relays and high limit (liquid expansion type) |

|---|

| Total input | Blower three-phase 200V: 1.5kW 8.0A

Burner single-phase 200V: 0.24kW 1.5A | Blower three-phase 200V: 3.0kW 12.0A

Burner single-phase 200V: 0.24kW 1.5A | Blower three-phase 200V: 4.0kW 16.0A

Burner single-phase 200V: 0.24kW 1.5A |

|---|

※The specifications above refer to the type utilizing the existing foundation, while the flat foundation type will have (‐F) added at the end of the model number. The double-inlet centrifugal multi-blade blower (2 units) (JCSD type) is also available in the lineup.

- Type utilizing existing foundation: This type uses the existing foundation directly, so no foundation work is required. (Applicable when existing equipment is arranged in a single building).

- Flat foundation type: Requires the construction of a special flat foundation with a depth of 420mm, with each unit being installed individually.

※These specifications may be changed without prior notice for improvement purposes.

Main unit side (and microcomputer bulk device)

Main unit side (and microcomputer bulk device) Inside the drying chamber

Inside the drying chamber As a result, insulation performance improves significantly by using color steel plates for the outer surface, injecting high-density foam polyurethane inside, and replacing the traditional aluminum frame with a resin frame.

As a result, insulation performance improves significantly by using color steel plates for the outer surface, injecting high-density foam polyurethane inside, and replacing the traditional aluminum frame with a resin frame. As a result, the heat loss to the foundation section is significantly reduced.

As a result, the heat loss to the foundation section is significantly reduced. Traditional dryer

Traditional dryer EC-type dryer

EC-type dryer

Equipped with a 5.7-inch high-definition touch panel

Equipped with a 5.7-inch high-definition touch panel

Reducing operational effort

Reducing operational effort

Focused on essential information only

Focused on essential information only Minimizes operational errors, with immediate alert notifications

Minimizes operational errors, with immediate alert notifications Expert drying methods

Expert drying methods A dedicated program menu screen has been provided

A dedicated program menu screen has been provided