Sanshu Sangyo

Sanshu Sangyo SK Series L-type Greenhouse Heater

Manufacturer: Sanshu Sangyo Co., Ltd.

Model: SK Series L-type

Four performances have evolved

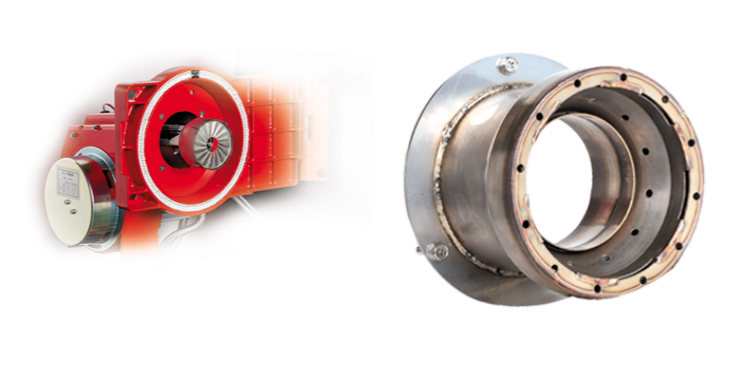

1.Equipped with a new burner

Achieving high combustion efficiency

The high-efficiency split flame combustion is maintained, and cleaning has become easier with the detachable burner top.

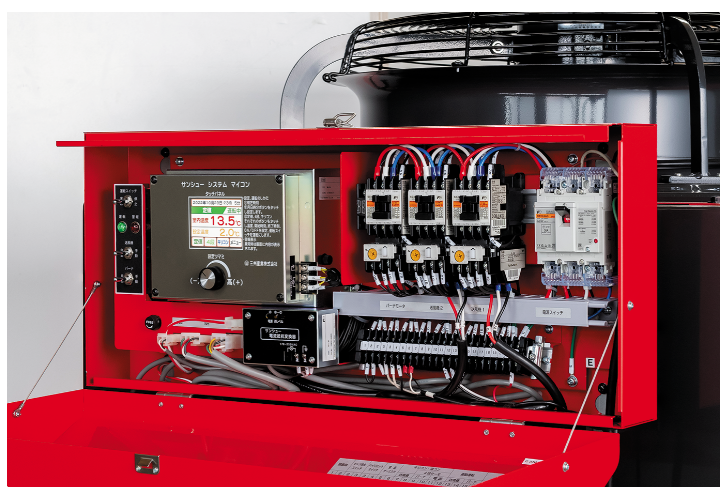

2.Microcomputer (Control unit)

Standard equipped with 4-stage thermostat and on/off controller

The cooling time for the blower fan is automatically adjusted according to the combustion time. The alarm device is optional.

3.Newly adopted ZAM® steel plate

Improved corrosion resistance of the main unit

The use of highly corrosion-resistant ZAM®+ for the outer panels has enhanced durability. You can use it with peace of mind for a long time.

※ ZAM® is a registered trademark of Nippon Steel Corporation.

4.Newly designed balance plate

Improved durability of the furnace

Maintains high thermal efficiency while suppressing the generation of condensation inside the furnace.

DF: Down-blow type

| SK-200L-DF | SK-300L-DF | SK-400L-DF |

|  |  |

| SK-500L-DF | SK-600L-DF | |

|  |

UF: Up-blow type

| SK-200L-UF | SK-300L-UF | SK-400L-UF |

|  |  |

| SK-500L-UF | SK-600L-UF | |

|  |

T: Low-floor type

| SK-500LT-DF | SK-600LT-DF | SK-700LT-DF SK-800LT-DF |

|  |  |

Specification sheet

| Model / Item | SK-200L | SK-300L | SK-400L | SK-500L | SK-500LT | SK-600L | SK-600LT | SK-700LT | SK-800LT | ||||||||

| DF | UF | DF | UF | DF | UF | DF | UF | DF | DF | UF | DF | DF | DF | ||||

| Combustion output | kw | 58.1 | 87.2 | 116.3 | 145.3 | 174.4 | 209.3 | 232.6 | |||||||||

| (kcal/h) | (50.000) | (75.000) | (100.000) | (125.000) | (150.000) | (180.000) | (200.000) | ||||||||||

| Standard heating area | m² | 495〜660 | 660〜990 | 990〜1,320 | 1,320〜1,650 | 1.650-1,980 | 1,960〜2310 | 2310〜2640 | |||||||||

| (Tsubo) | (150-200) | (200-300) | (300〜400) | (400〜500) | (500-600) | (600-700) | (700-800) | ||||||||||

| Thermal efficiency | % | 90 | |||||||||||||||

| Burner | Electric motor | W | 150 | 250 | 400 | ||||||||||||

| Nozzle capacity | G/H | 1.35 | 2.00 | 2.75 | 325 | 4.00 | 5.00 | 5.50 | |||||||||

| Weight | L/h | 6.4 | 9.5 | 12.6 | 15.8 | 19.0 | 22.8 | 25.3 | |||||||||

| Spray angle | Degree | 80 | |||||||||||||||

| Fuel oil | – | AM oil | |||||||||||||||

| Nozzle heater | w | 250 | |||||||||||||||

| Blower fan | Type | – | Pressurized propeller fan | ||||||||||||||

| Electric motor | w | 750 | |||||||||||||||

| Units | Unit | 1 | 2 | 3 | |||||||||||||

| Airflow | m²/min | 96 | 125 | 200 | 290 | 330 | |||||||||||

| Control device | Control method | – | Two-position (ON-OFF) control by microcomputer | ||||||||||||||

| Temperature controller | – | Thermistor type (Microcomputer: adjustable from 0〜35°C) | |||||||||||||||

| Safety devices | – | 1.Combustion safety control device 2.Overheat prevention device 3.Electric motor overload protection device 4.Blower fan timer 5.Hinge safety switch 6.Seismic sensor connection terminal | |||||||||||||||

| Polyduct folding width at exhaust outlet | mm | 630×2 | 450×4 | 900×2 | 460×6 | 900×2 | 450×8 | 1.100×2 | 450X10 | 1.100×2 | 450×12 | 1.100×2 | |||||

| Chimney diameter | mm | 0150 | ¢230 | ||||||||||||||

| Fuel pipe connection diameter | – | R3/4 | |||||||||||||||

| External dimensions | Overall width | mm | 760 | 950 | 1,070 | ||||||||||||

| Overall length (*1) | mm | 2,050 | 2,510 | 2,900 | 3.070 | 3.310 | |||||||||||

| Overall height | mm | 1,520 | 1,500 | 1,500 | 1,480 | 1,500 | 1,480 | 1,780 | 1,760 | 1,380 | 1,780 | 1,760 | 1.380 | 1.580 | |||

| Electrical capacity | Three-phase 200V | Rated output | W | 1.150 | 1.900 | 2.000 | 2.900 | ||||||||||

| Rated current | A | 6.3 | 9.9 | 10.6 | 14.0 | ||||||||||||

| Effective heat transfer area | m² | 3.38 | 4.57 | 5.12 | 8.21 | 9.05 | 12.36 | ||||||||||

| Total weight | kg | 320 | 310 | 380 | 360 | 410 | 400 | 650 | 630 | 570 | 680 | 650 | 610 | 780 | |||