Sanshu Sangyo

Sanshu Sangyo Vapor Heat Treatment System For Base Rot Disease

Manufacturer: Sanshu Sangyo Co., Ltd.

Vapor Heat Treatment System for Sweet Potato Base Rot Disease

In February 2021, the National Agriculture and Food Research Organization (NARO) Agricultural Research Support Center published the “Sweet Potato Base Rot Disease Ecology and Control Measures – For Technicians (FY2020 Edition).” The latest FY2022 edition recommends “Vapor Heat Treatment at 48°C and 95% constant temperature and humidity for 100 minutes.”

For detailed treatment programs, please refer to the FY2022 edition (link to the latest version below).

For sweet potato vapor heat treatment, maintain a program that prevents heat damage to the tubers by closely balancing sterilization and damage temperatures. Ensure precise, uniform control to eliminate unevenness.

In 2021, our company collaborated with starch manufacturing companies, bio-seedling manufacturing companies, and others to conduct vapor heat treatment on 30 tons of sweet potatoes by January 2022, demonstrating its effectiveness. Furthermore, through independent testing, we improved accuracy and achieved the capability to process up to 500 kg in one chamber.

To prevent unnecessary steps, such as transferring the tubers and causing damage, we developed a technology allowing vapor heat treatment directly within the harvest containers typically used in production fields. This technology is registered as a utility model.

Additionally, to enable precise temperature control, the vapor heat treatment system uses electric heaters as a heat source.

Given the need for a carbon-neutral and decarbonized society, we have developed an energy-saving model that uses waste hot water discharged from factories. The new model supports operation using electric heaters only, a hybrid of electric heaters and hot water, or hot water only, depending on the situation (patent pending).

- Utility Model Registration: No. 3236140

- Design Registration: No. 1720661

- Trademark Registration: No. 6570474

Caution!

Perform steam heat treatment of sweet potatoes under precise temperature and humidity control, following correct treatment parameters. Failure to do so may result in damage to the valuable sweet potatoes.

What is Sweet Potato Base Rot Disease?

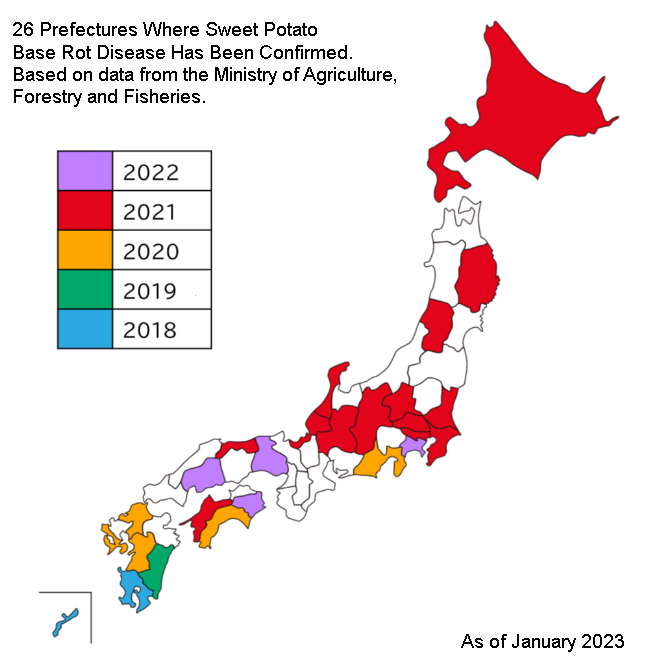

Sweet potato base rot disease was first confirmed in Japan in November 2018. It is caused by a filamentous fungus (Diaporthe destruens, formerly known as Plenodomus destruens). When this disease occurs, the leaves discolor and show poor growth, the base of the stem blackens and rots, and the underground sweet potato itself becomes discolored from the stem area and emits a moldy odor.

As of the end of June 2022, it has been confirmed in 26 prefectures, including Okinawa, Kagoshima, and Miyazaki.

The fundamental countermeasures for sweet potato base rot disease are the “three no’s”:

- Bring it in.

- Let it spread.

- Leave it behind.

To prevent the introduction of the fungus through seedlings, it is important to disinfect the seed potato beds, main fields, and seed potatoes or seedlings to promote the development of healthy seed stock.

Delivery Record

As of March of the 5th year of Reiwa (2023), 11 units of this product have been delivered. Additionally, two small test devices have been delivered to research institutions.

For sweet potatoes harvested in the 5th year of Reiwa (2023), hundreds of tons of seed potatoes were vapor heat treated using our vapor heat treatment equipment and other facilities in Kagoshima and Miyazaki prefectures.

The first step in implementing countermeasures for sweet potato base rot disease—“Do not bring it in”—has officially begun!