Gore (日本ゴア)

GORE-SELECT Membranes (PEM) for Fuel Cells

Manufacturer: Gore (日本ゴア)

Made in Japan

Product type: Membranes

Overview of Membranes

Hydrogen fuel cell technology addresses the challenges OEMs across the automotive and heavy-duty transportation sectors face as they transition to more sustainable and efficient clean energy sources. Proton exchange membrane (PEM) technology has been increasingly used in passenger vehicles due to its high-power density, durability, and efficiency.

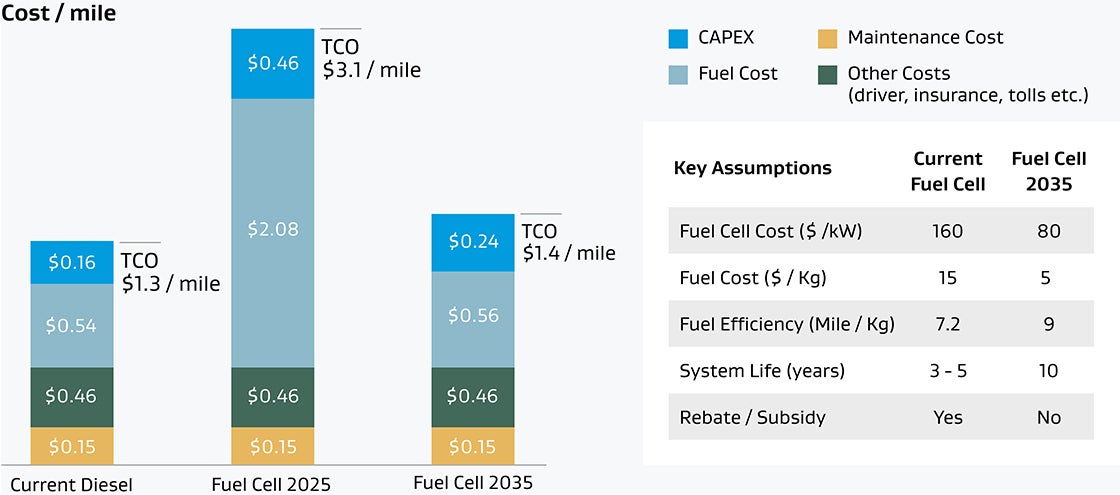

With a 50% decline in total cost of ownership (TCO) forecast over the next decade for fuel cell electric vehicles, PEM will play a pivotal role in the transition to clean transportation.

For heavy-duty vehicles (HDV), fuel cell membranes address the increasing demands for higher power output, extended operation lifecycle, and smaller systems while approaching cost parity with diesel. With the right PEM fuel cell membrane manufacturer, OEMs can minimize trade-offs in achieving minimal TCO.

PEM fuel cell membranes help OEMs lower total cost of ownership in the long-term.

Gore: A Leader in PEM Fuel Cell Technology

For over 25 years, Gore has partnered with nearly all the major fuel cell system developers and OEMs worldwide.

Gore has:

R&D leaders can rely on Gore’s extensive expertise and TCO approach to identify efficient, cost-effective solutions for the global transportation industry.

High performing, durable fuel cell membranes.

25 years fuel cell manufacturing expertise and consultation.

Proven, stable supply chain with reliable delivery.

Consistent product uniformity – ISO 9001 and 14001 certified.

Features & Benefits

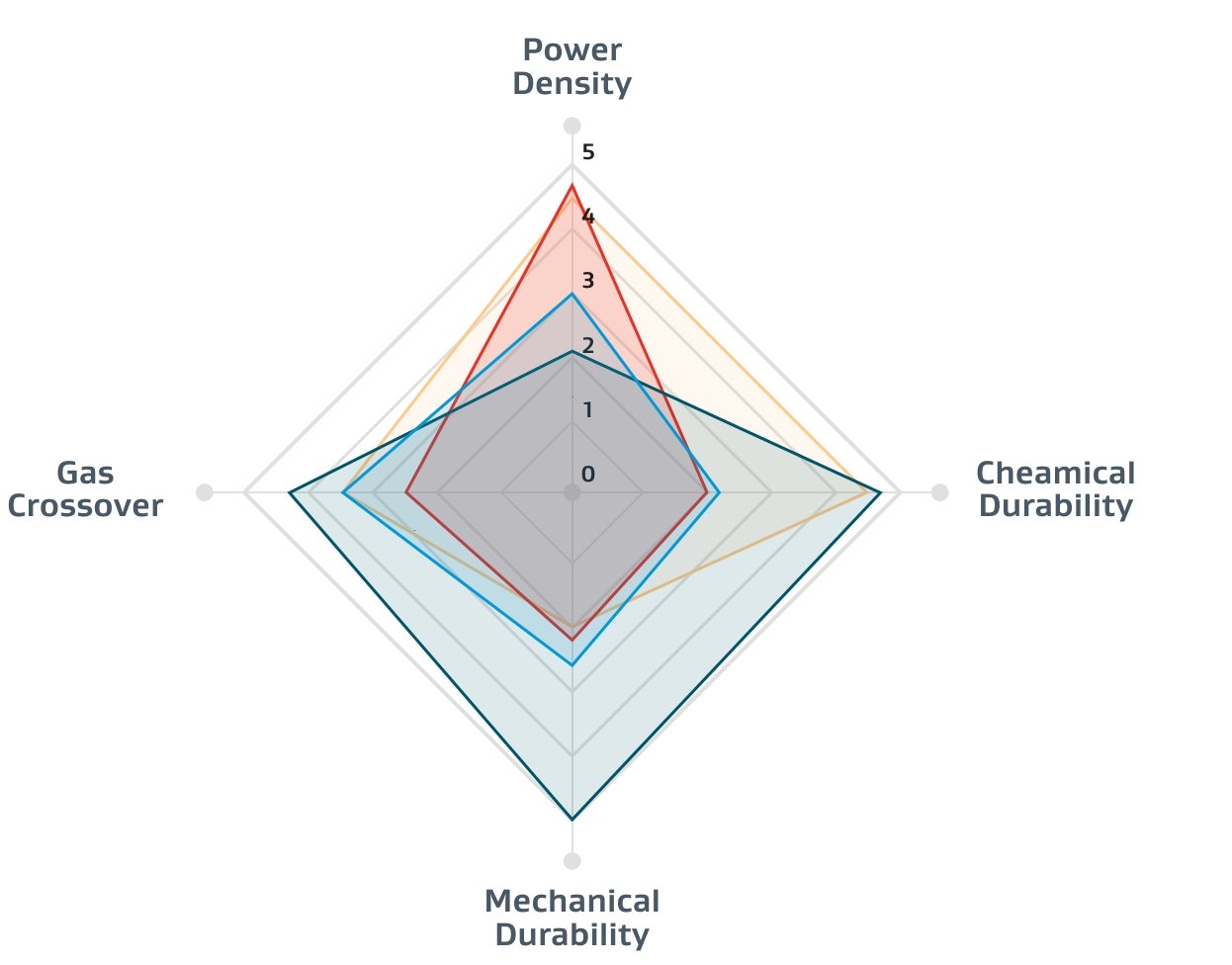

PEM fuel cell design can have a significant impact on overall system costs. Designs must consider both the upfront capital expenditure (CAPEX) and operating costs (OPEX) over the vehicle lifetime. Our reinforced, thinner GORE-SELECT® Membrane PEM reduces the trade-off between power density, durability, and gas crossover.

Minimizing Trade-Offs While Reducing TCO

OEMs can leverage Gore’s expertise and product leadership in identifying pathways to lower total cost of ownership in heavy-duty fuel cell applications.

Key Advantages

With the unique thinner, ePTFE-reinforced design of GORE-SELECT® Membrane PEM, manufacturers can be confident their requirements for performance, reliability, and cost are met with minimal compromises.

REDUCE OVERALL STACK COSTS

GORE-SELECT® Membranes offer lower proton resistance (high proton conductivity) to help reduce overall upfront and operational stack costs.

IMPROVE FUEL EFFICIENCY

Lower proton resistance (high proton conductivity) enables fuel cell stacks to operate at higher voltage and deliver the same power output. This can result in improved fuel efficiency and lower operating costs.

MITIGATE MECHANICAL DEGRADATION AND CHEMICAL CONTAMINATION

Even in extreme operating conditions, our strong, long-lasting PEM ensures high mechanical and chemical durability resulting in long-term reliability that contributes to lower overall costs and TCO.

Applications

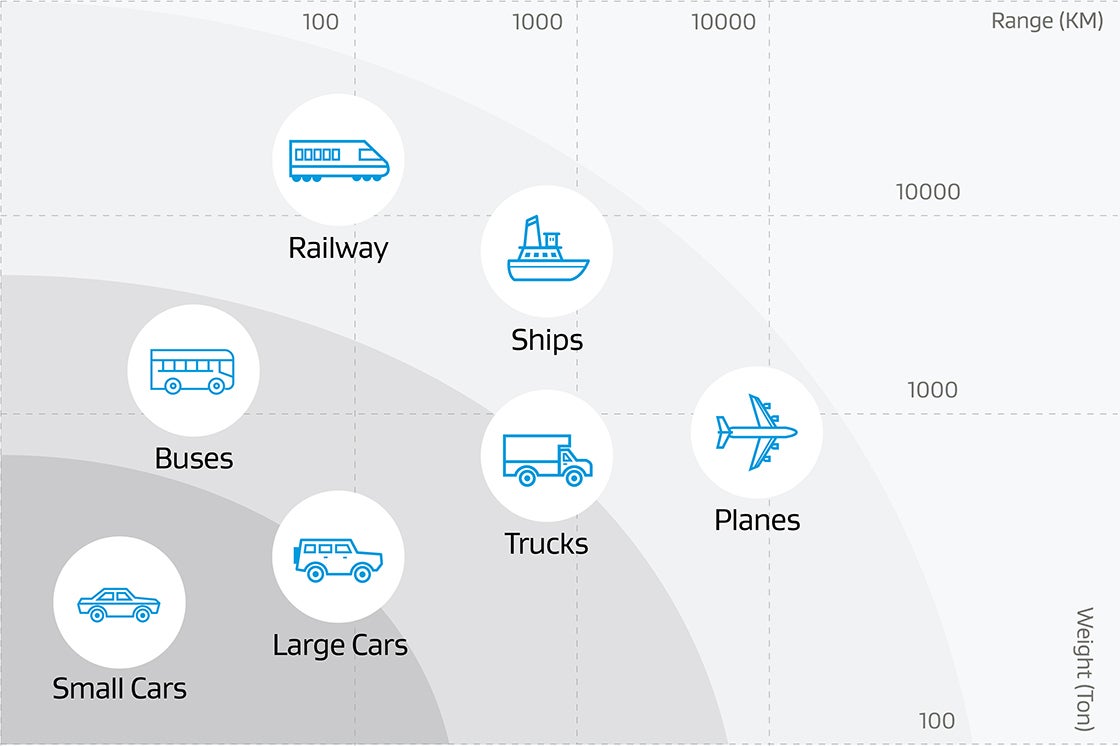

Fuel cells’ higher energy density offers greatest value to applications that are of higher weight and require higher power and greater range, such as commercial vehicles and diesel replacement applications.

Technical Specs

The GORE-SELECT® Membrane: Product Line Up

| Membrane Name | Lead Application / Market | Value |

|---|---|---|

| M775.15 | Commercial vehicle and other heavy-duty applications | High chemical durability & high power density |

| M788.12 | Automotive, back-up power, range extender, fork-lift and portable | High mechanical durability & low gas permeance & cost-effective |

| M765.08 | Passenger vehicle | High power density under dry condition & cost-effective |

| M665.12 | Stable power generation | High chemical and mechanical durability |

For information about GORE-SELECT® Membranes M735.18 and M740.18, please contact your local Gore representative.

GORE-SELECT® Membrane Attributes

Each GORE-SELECT Membrane achieves these key characteristics to varying degrees, according to operational requirements and customer-defined specifications. This allows us to offer solutions that are optimized for multiple industries and applications.