IMC Co., Ltd.

IMC Trimmer (Hydraulic Automatic Lathe)

Manufacturer: IMC Co., Ltd.

Product: Trimmer (Hydraulic Automatic Lathe)

Features and Effects of Introducing the “Trimmer”

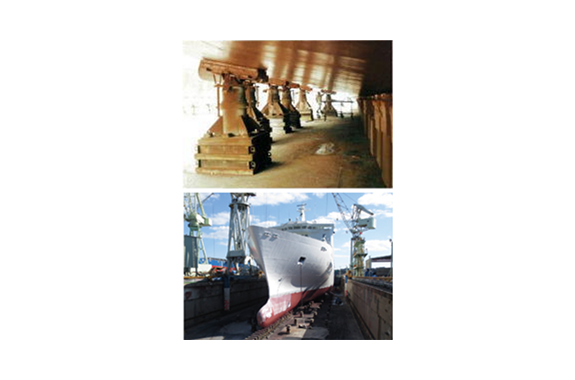

1. It reduces the labor required for skilled workers to adjust the height of blocks and the inclination of the top surface.

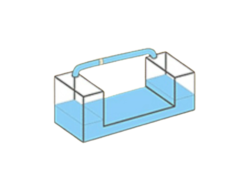

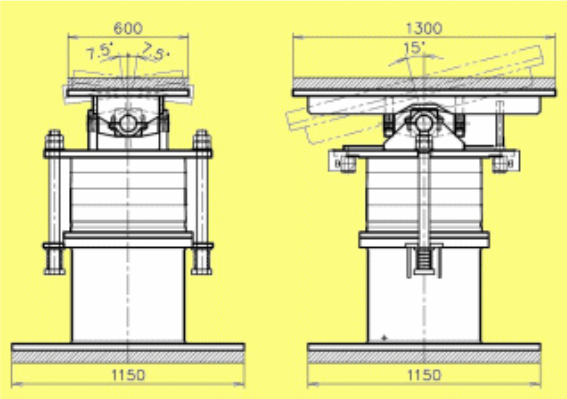

The top plate on the top of the “trimmer” can freely move 15 degrees on each side in the length direction and 7.5 degrees on both sides in the width direction.

In addition, the vertical stroke is 250 to 300 mm, so it automatically fits to the shape of the ship’s bottom.

2. There is no risk of damage to the hull due to excessive localized reaction forces

. The hull only receives reaction forces up to the support load. In addition, the reaction force is received evenly from the entire surface of the top plate.

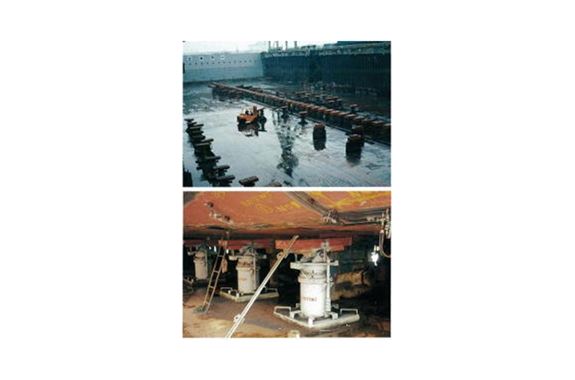

3. Improves traffic and transportability in the culvert.

Since it is a self-supporting type that does not require piping or wiring for power, it can be moved freely and keeps the culvert neat.

4. Easy maintenance and high reliability.

The structure is simple and does not require piping or wiring. Stainless steel and anti-corrosive paint are used for the exterior, which is alternately exposed to seawater and air, and important parts such as valves are housed inside where they do not come into contact with seawater.

5. Partial replacement of the bottom shell can be easily performed.

Even when the hull is supported, the top plate can be lowered by operating the valve and the Trimmer body can be easily moved. It can also be easily restored by filling it with gas.

6. Dockside running gear can be used.

No side supports are required to prevent the hull from tipping over.

| Model | 50-300-H | 30-300-H | 30-250-H |

| Support load | 490kN (50t) | 294kN(30t) | |

| stroke | 300mm | 300mm | 250mm |

| Minimum Shrinkage Height | 1410- 1530mm | 1410- 1530mm | 1165- 1285mm |

| weight | Approx. 1,730 kg | Approx. 1,730 kg | Approximately 1,600 kg |