Fukuda Seiko, Japan

Fukuda TMS Kit B-Safe Spindle Monitoring System

Made in Japan

Manufacturer: Fukuda Seiko

Model: TMS Kit

Features

B-Safe is optimized for the diagnosis of spindles and other machine tools by means of vibration and temperature condition analysis. By attaching the miniaturized sensor directly to the measurement point, various abnormalities can be monitored in real time. The latest version of the X offers enhanced predictive maintenance capabilities to further reduce machine downtime.

- LED alarms and high-capacity battery monitor impacts during transportation.

- Constant monitoring of real-time acceleration in XYZ 3-axis, high-resolution vibration waveform in 1-axis, and temperature

- Sensor’s built-in memory stores up to 2000 time-stamped alarm histories

- When a collision is detected, the vibration acceleration waveform for 5 seconds before and after is automatically recorded.

- Appropriate maintenance cycle is proposed by the operation statistics function.

use

- Machine tool spindle condition monitoring

- Anomaly Detection

- Anomaly Records

- Operational Statistics

- Preventive Maintenance

- Predictive Maintenance

- Machine tool spindle condition monitoring

Innovative Solutions

- 3-axis accelerometer realized by hybrid MEMS* technology

* Micro Electro Mechanical System: A micro device that integrates and combines ICs and micromachines

- Built-in piezoelectric element and temperature sensor for high-frequency vibration and temperature analysis

- Stand-alone drive and real-time logging realized by integrating memory into the sensor

body (data useful for analyzing bearing behavior such as collisions, imbalances, overloads, abnormal work cycles, wear and loss of tools, etc. are recorded and accumulated. )

Multi-platform software

HMI (Human Machine Interface) software, which is highly coordinated with B-Safe sensors, enables remote monitoring of the production line.

Always-on, multi-platform software allows you to get a lot of information from the machines you are running.

dashboard

The B-Safe HMI (Human Machine Interface) has been developed with the concept of simplicity and intuitiveness so that all information can be understood at a glance.

The latest version allows you to manage more sensors and monitor and control multiple machines simultaneously.

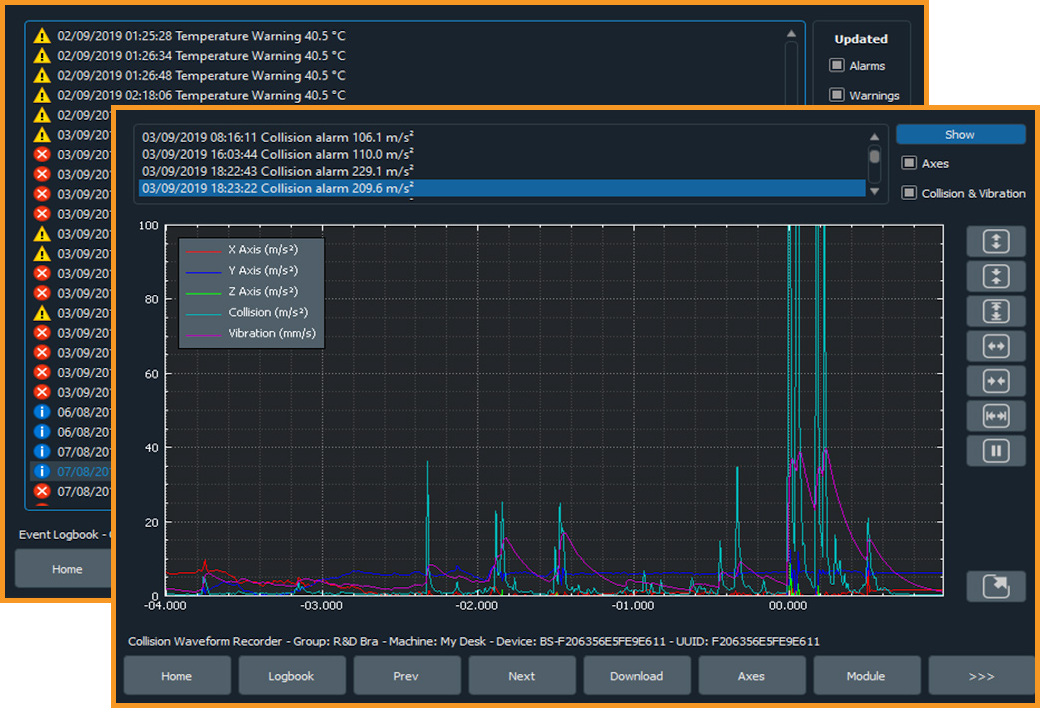

Event

The intuitive infographic of the event log feature gives you instant visibility into all activities, including abnormal alarms, warnings, check-ups, power shutdowns, and more.

When a spindle collision is detected, the system records a detailed vibration waveform for 4 seconds before and 1 second after, so that the cause can be investigated later.

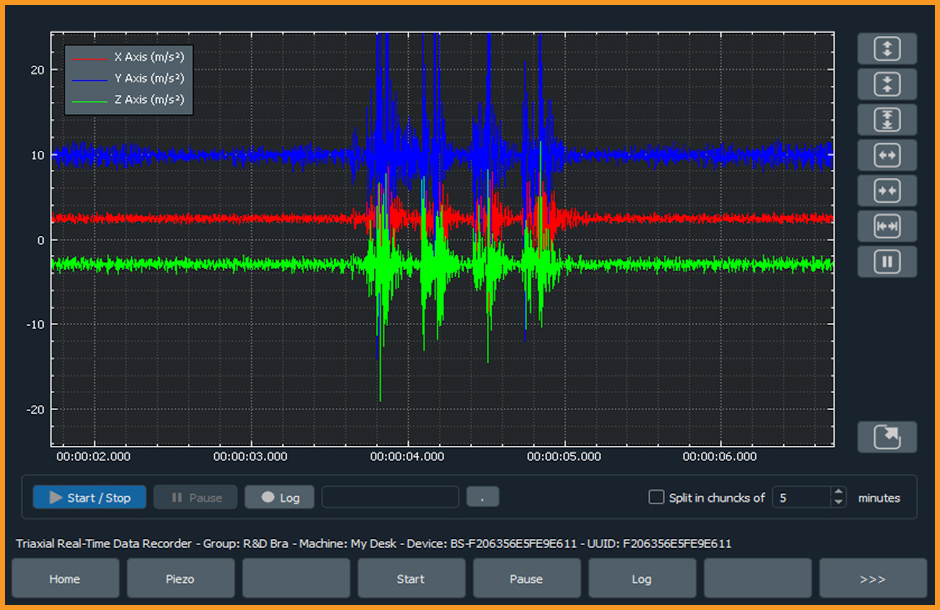

Real-time data

All sensor data (temperature sensor, 3-axis MEMS sensor, high-frequency 1-axis piezo sensor) can be monitored in real time with the B-Safe HMI software.

The B-Safe system is completely self-sustaining and manages your data. Measurement data can be exported in real time or at any time.

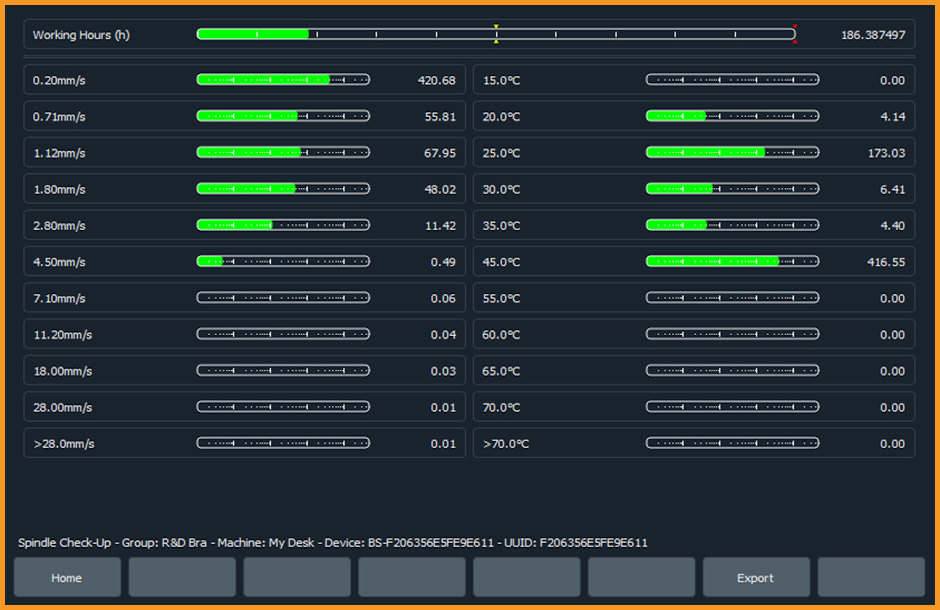

trend

Weighting statistical or trend data and customizing thresholds are included. Respond to diversifying needs.

The B-Safe cloud app also provides remote access to the ability to monitor and evaluate spindle conditions.

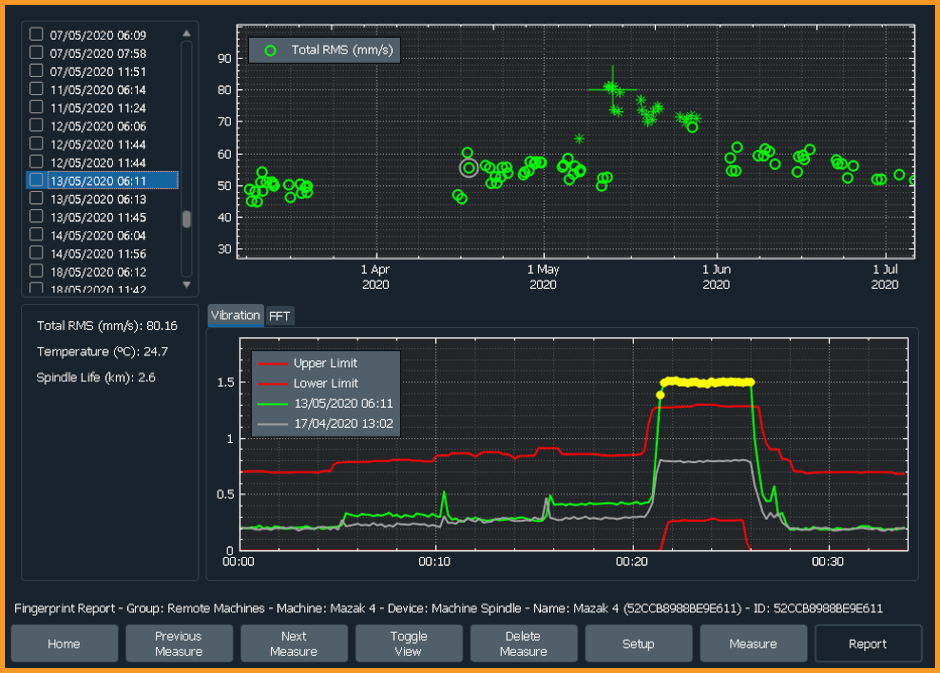

Fingerprint

This option, which is a predictive maintenance function, compares the operation tendency that differs for each spindle to a “fingerprint”, and records and learns the operation trend = “fingerprint” unique to that individual.

By accumulating machine vibration profiles obtained from daily routine operations (e.g., daily check recipes) over time, predictive signals of failure emitted from shafts and bearings can be visualized as alerts.

specification

| Sensor Dimensions | M12 x 1.0 – L41 mm (connector type) M12 x 1.0 – L32 mm (direct cable type A)M16 x 1.5 – L22 mm (direct cable type B) |

| Cable length | 5m (standard)* * Various extension adapters and cables are available |

| MEMS Sensors | ±156.96 m/s2 (±16 g) – 1,000 Hz |

| Piezo sensor | ±490.50m/s2 (±50 g) – 10 kHz |

| Operating Temperature | -40℃ ~ 85℃ |

| Shock resistance | 98,100 m/s2 (10,000 g) |

| Communication Protocols | Modbus TCP / Modbus RTU on RS485 |

Related Products

-

Vessel No.D73H550 Measurement bits (H5mm)

-

Watanabe RSK [Sheath RTD] Wall-mounted Type Straight Type

-

Hammer Caster 423S-URB Urethane Thermosetting Wheel

-

SAKUSAKU 4SS-25D 3.0S Carbide Square End Mill 4-Flute

-

Hosoda Ferrous & Non-Ferrous Metal Materials & Products

-

Tosei Sharyo GLL-DC24V Series Mechanical Lift