Kuwana Metals

Kuwana Metals SAM PS200 Series Pressure-Based PI Mass Flow Controller

Manufacturer: Kuwana Metals, Ltd.

Model : SAM PS200 Series

Features

- Pressure-based flow measurement architecture

- Improved Pressure Insensitive function

- Valiant repeatability

- Self-diagnostic function

Electrical Connection

Analog model 9 Pin D-sub male type (M3 screw)

| 1 | VALVE OPEN / CLOSE Connect to +15 V: OPEN Connect to -15 V: CLOSE |

| 2 | OUTPUT (0 – 5 VDC / 0 – 100 %F.S.) |

| 3 | INPUT POWER (+15 VDC) |

| 4 | POWER COMMON |

| 5 | INPUT POWER (-15 VDC) |

| 6 | SET POINT INPUT (0 – 5 VDC / 0 – 100 % F.S.) |

| 7 | SIGNAL COMMON |

| 8 | SIGNAL COMMON |

| 9 | VALVE VOLTAGE OUTPUT (0 – 4V / 0 – 100 %) |

RS-485 model 9 Pin D-sub male type (M3 screw)

| 1 | NA |

| 2 | NA |

| 3 | INPUT POWER (+15 VDC) |

| 4 | POWER COMMON |

| 5 | INPUT POWER (-15 VDC) |

| 6 | NA |

| 7 | SIGNAL COMMON |

| 8 | RS-485+ |

| 9 | RS-485- |

DeviceNet™ model CM02-8DR5P-CF (D5) DDK

| 1 | SHIELD |

| 2 | INPUT POWER (+11 – 25 VDC) |

| 3 | GND(-) |

| 4 | CAN(H) |

| 5 | CAN(L) |

EtherCAT® model (Power connector) XS3M-M524-201 OMRON

| 1 | +24VDC |

| 2 | FG |

| 3 | POWER COMMON (0V) |

EtherCAT® model (Communication connector) Cat.5 RJ45 Ethernet connector

| Category 5 networking Ethernet cable is used. |

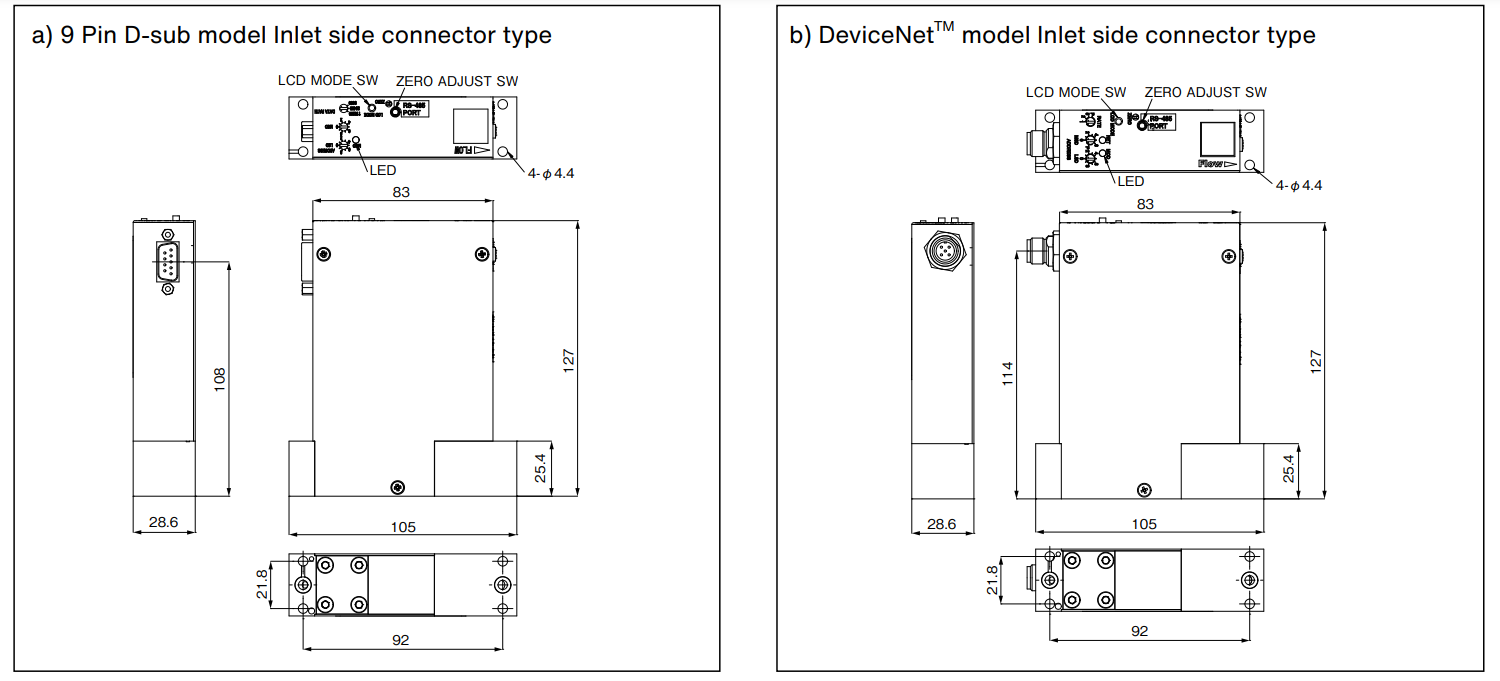

Dimensions

- 1.125” IGS™ fitting

Specifications ※ 1

| Items | Normal pressure type | Low vapor pressure type (C4F6, C4F8 or similar gas) |

|---|---|---|

| Full-Scale Range (N2 equivalent flow) | From 5 SCCM to 5 SLM (Multi-0~10) | |

| Flow Sensing | Measurement of the differential pressure | |

| Flow Calibration | Multi Gas, Multi Range (11 BINs) | |

| Settling Time (SEMITM E17-91)※2 | < 0.8s (< 0.6s (typical)) | |

| Accuracy (N2)※3 | < ±1% S.P. (10–100%), < ±0.1% F.S. (2-10%) | |

| Linearity | < ±0.5% F.S | |

| Repeatability | < ±0.25% S.P. (20-100%), < ±0.05%F.S. (2-20%) | |

| Leak Integrity | < 1×10-11Pa・m3/s (He) | |

| Flow Control range※4 | 0.5–100% F.S. | |

| Operating Pressure Range (Inlet) | 230-700kPa (abs) | 140-700kPa (abs) |

| Operating Pressure Range (Outlet) | Vacuum-80kPa (abs) | Vacuum-60kPa (abs) |

| Leak Across Valve | <0.5% F.S., <0.1% F.S. (in case that the full-scale is set for each BIN) | |

| Proof Pressure | 1.0MPaG | |

| Ambient Temp. Range | 15-50 ºC [Gas temperature needs to be equal to ambient temperature.] | |

| Accuracy of the internal pressure sensor | < ±5kPa [0-700kPa (abs)] | |

| Accuracy of the internal temperature sensor | << ±1 ºC [15–50 ºC] | |

| Control Valve Type | Normally-Closed Piezo Actuator | |

| Materials for external seals | 316L S.S | |

| Materials for gas wetted | 316L S.S., PCTFE, Ni-Co alloy | |

| Fittings | 92mm 1.125” Cseal, 92mm 1.125” WsealTM | |

| Surface Finish | Electro-polished (fitting, sensor, base) Ra=0.2μm, machine finish Ra=0.8μm | |

| Orientation | Any position | |

| Mass | 1.1kg | |

| Special function | Pressure Insensitive function microSDTM card, LCD Display to monitor the various parameter | |

| Signal interface | Analog, Digital (RS485, DeviceNetTM, EtherCAT®) | |

| Connector type | Analog : 9Pin D-sub Digital : RS485, DeviceNetTM, EtherCAT® Maintenance : RS485/Φ2.5 3-pole round connector (for all model) | |

| Input power | Analog : +15VDC ±4% 90mA, -15VDC ±4% 60mA DeviceNetTM : +11VDC 500mA – +25VDC 230mA EtherCAT® : +24VDC ±10% 120mA | |

| Flow set signal (Analog model only) | 0–5VDC / 0–100%F.S. input impedance > 1MΩ | |

| Flow out signal (Analog model only) | 0–5VDC / 0–100%F.S. load impedance > 2kΩ (required) | |

- ※1. This specification is defined based on our standard test condition with single MFC. The performance with the different condition may not satisfy

this specification, and we do not guarantee this specification under the condition with all combination of the configuration. - ※2. From 0% to 5%S.P. or greater, ambient temperature is 22ºC (Min. 15ºC, Max. 50ºC)

- ※3. Digital mode, ambient temperature is 22ºC (Min. 15ºC, Max. 50ºC, Only when the temperature changes within ±3°C

after zero point adjustment is performed in the ambient temperature.) - ※4. Valve closes if the set point applies less than 0.5%F.S.

SCCM, SLM are the unit indicates the gas flow-rate as mL/min, L/min at 0ºC, 101.3kPa (abs) condition.

F.S. = full scale, S.P. = set point

PS200 series model and the suffix codes

| Category | Description | Suffix Codes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Measurement of the differential pressure | PS200 | |||||||||

| Interface | Analog (9Pin D-sub) | A | |||||||||

| DeviceNet™ | D | ||||||||||

| L Protocol RS-485 (9 Pin D-sub) | L | ||||||||||

| EtherCAT® | E | ||||||||||

| Connector location | Top L Protocol (RS-485) model is excluded. | T | |||||||||

| Inlet side | U | ||||||||||

| External Seals | Metal seal | M | |||||||||

| Valve Type | Normally-closed | C | |||||||||

| Fitting | 92mm 1.125″ Wseal™ | BW1 | |||||||||

| 92mm 1.125″ Cseal | BA1 | ||||||||||

| Fixed Code | 0 | ||||||||||

| Optional Code | NNN | ||||||||||

| Full Scale Range | 5 to 12 SCCM | Multi-0 | |||||||||

| 13 to 20 SCCM | Multi-1 | ||||||||||

| 21 to 40 SCCM | Multi-2 | ||||||||||

| 41 to 60 SCCM | Multi-3 | ||||||||||

| 61 to 100 SCCM | Multi-4 | ||||||||||

| 101 to 200 SCCM | Multi-5 | ||||||||||

| 201 to 300 SCCM | Multi-6 | ||||||||||

| 301 to 500 SCCM | Multi-7 | ||||||||||

| 501 to 1000 SCCM | Multi-8 | ||||||||||

| 1001 to 2500 SCCM | Multi-9 | ||||||||||

| 1001 to 2500 SCCM | Multi-9 | ||||||||||

| 2501 to 5000 SCCM | Multi-10 | ||||||||||

| Example | PS200ATMCBA10NNN Multi-5 | ||||||||||

| Pressure-based MFC, Analog control, Top connector, 9Pin D-sub connector, metal seal, Normally closed piezo valve, 1.125” 92mm Cseal, no option, Full scale 200SCCM | |||||||||||

Related Products

-

Kuwana Metals Aera FC-R7700 Series Mass Flow Controller

-

Kuwana Metals SAM 1480G / 2480G Series Mass Flow Controller

-

Kuwana Metals S-A075M Chilled Tower

-

Kuwana Metals Aera Transformer Digital Mass Flow Products

-

Kuwana Metals FCMB35-10/FCD-S/SCS Series/WCB/A105/F304/PE80 Valves

-

Kuwana Metals Aera FC-R7800 Series Mass Flow Controller