Osaka Blower MFG. CO., LTD.

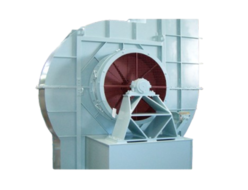

Osaka Blower Multi-Blade Fan

Manufacturer: Osaka Blower

Product Type: Multi-Blade Fan

Structure

The impeller consists of several dozen forward-curved blades that are shallow in the radial direction and long in the axial direction. The ends of the blades are riveted or welded to the main circular plate and side plate. The side plate and boss are firmly secured with multiple tie bolts, creating a strong structure. Combined with a comprehensive dynamic balancing test, this design ensures durability even at high rotational speeds.

The casing is primarily made of thick plate material, reinforced with structural steel to withstand mechanical and environmental conditions and ensure long-term durability.

The bearings used are typically ball or roller bearings, all of which are designed for long service life.

In addition, special materials such as stainless steel, Hastelloy, titanium, PVC, and high-tensile steel plates are used for heat resistance (up to approximately 1000°C), chemical resistance (acid resistance), and other specific requirements. Special structures, such as double-layer insulated casings, have also been successfully designed and manufactured.

Features and Applications

The multi-blade fan (also known as a Sirocco fan) is suitable for relatively low-pressure applications, with a pressure range of 0.1 kPa to approximately 1.5 kPa.

Its applications include:

- Ventilation for buildings and ships

- Heating, cooling, and air conditioning systems

- Drying applications

- Mine ventilation

- Boiler forced draft and induced draft

- High-temperature gas circulation for furnaces

Key Features

- Compared to other centrifugal fans, it has slightly lower efficiency.

- However, for the same pressure, it requires a lower airflow velocity, allowing for a more compact fan design.

- The pressure variation in response to airflow changes is minimal, making it suitable for systems with multiple inlets or outlets where opening or closing some ports does not significantly affect overall performance.

- On the downside, if resistance decreases and airflow increases, the required shaft power tends to rise sharply, requiring careful consideration during operation.

This type of centrifugal fan is one of the most widely used for stationary equipment on land. It is generally driven by a V-belt, though direct-drive and motor shaft-driven types are also available.